• T E C H N I C A L D A T A S H E E T •

MONOGRAM 36" WALL-MOUNTED HOOD

IMPORTANT SAFETY NOTICE

THIS INFORMATION IS INTENDED FOR USE BY

PERSONS POSSESSING ADEQUATE BACKGROUNDS

OF ELECTRICAL, ELECTRONIC AND MECHANICAL

EXPERIENCE. ANY ATTEMPT TO REPAIR A MAJOR

APPLIANCE MAY RESULT IN PERSONAL INJURY AND

PROPERTY DAMAGE. THE MANUFACTURER OR SELLER

CANNOT BE RESPONSIBLE FOR THE INTERPRETATION OF

THIS INFORMATION, NOR CAN IT ASSUME ANY LIABILITY

IN CONNECTION WITH ITS USE.

DISCONNECT POWER BEFORE SERVICING

IMPORTANT: RECONNECT ALL GROUNDING DEVICES.

ALL PARTS OF THIS APPLIANCE CAPABLE OF CONDUCTING

ELECTRICAL CURRENT ARE GROUNDED. IF IT IS NECESSARY

TO REMOVE GROUNDING WIRES, SCREWS, STRAPS, CLIPS,

NUTS OR WASHERS USED TO COMPLETE A PATH TO GROUND,

THEY MUST BE RETURNED TO THEIR ORIGINAL POSITIONS

AND PROPERLY FASTENED BEFORE POWER IS

RECONNECTED.

GROUNDING SPECIFICATIONS

Ground Path Resistance 0.10 Max.

Insulation Resistance 250K Min.

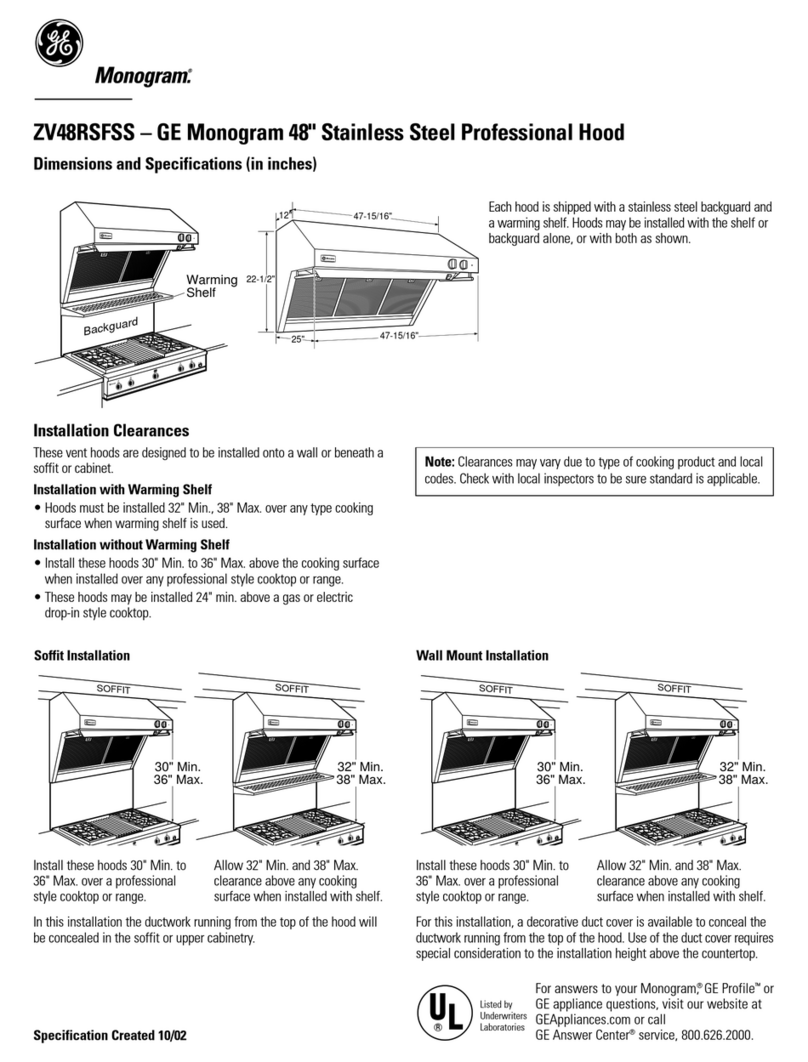

INSTALLATION REQUIREMENTS:

Power Supply

The hood must be connected to a supply circuit of the proper

voltage and frequency as specied on the rating plate. Wire size

must conform to the National Electrical Code or the prevailing local

code. The rating plate is located on the left side and is visible when

lter is removed.

WARNING: IMPROPER CONNECTION OF

ALUMINUM HOUSE WIRING TO COPPER LEADS CAN RESULT

IN A SERIOUS PROBLEM. USE ONLY CONNECTORS DESIGNED

FOR JOINING COPPER TO ALUMINUM AND FOLLOW THE

MANUFACTURER’S RECOMMENDED PROCEDURE CLOSELY.

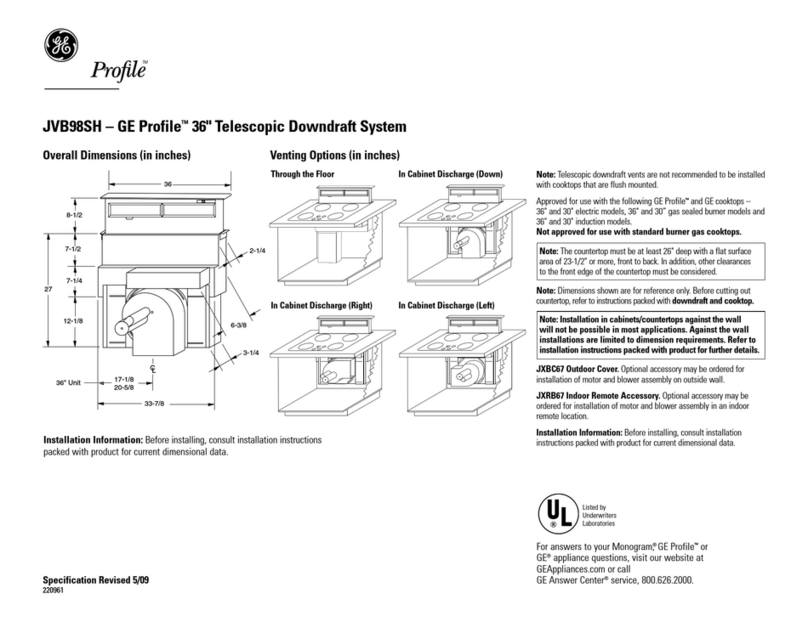

MODEL NUMBER ZV750/ZV755

IMPORTANT

SERVICE INFORMATION

DO NOT DISCARD

Pub. No. 31-14783

PUSH BUTTON OPERATION AND LED DISPLAY

Fan Keypad Operation

1 ON/OFF – Remembers the last fan speed used

2 Decreases speed

3 Increases speed

4 Boost speed

5 Delayed fan shutoff – Choose 5, 10 or 20 minutes by pushing

this button (see item 10).

Hood Lights Keypad Operation

6 Light ON/OFF – Remembers the last light level used

7 Dims light

8 Brightens light

Display LEDs

9 Clean indicator light illuminates after 30 hours of “ON” time

to remind you to clean the metal grease lters.The light

stays on until the lters are replaced. If the lights stay on

and the lters are in, adjust the right side lter in place.

Then the timer resets automatically.

10 Indicates the time the fan is set to run

11 Fan operating symbol

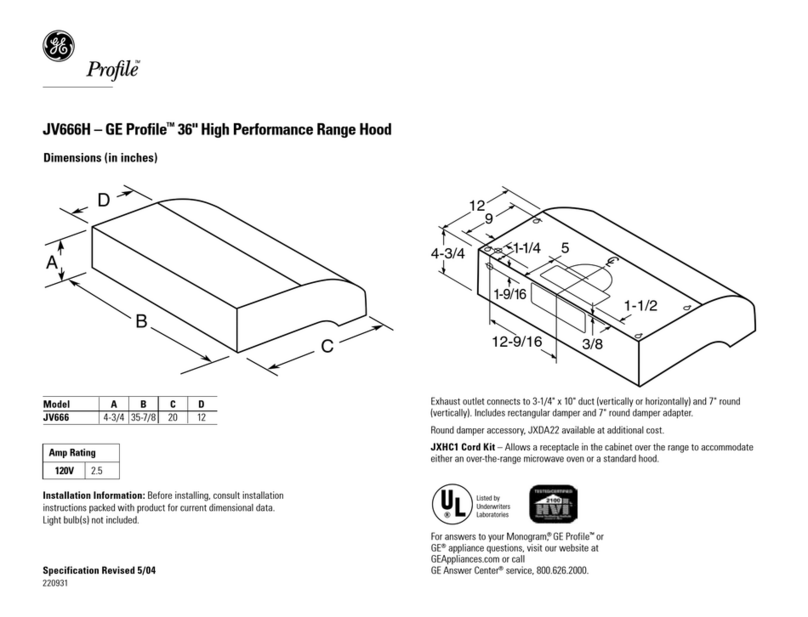

HALOGEN LAMPS

The four halogen lamps are the push-in type rated at 120V and

25 watts with a G-9 base.

TO CHANGE THE LAMPS

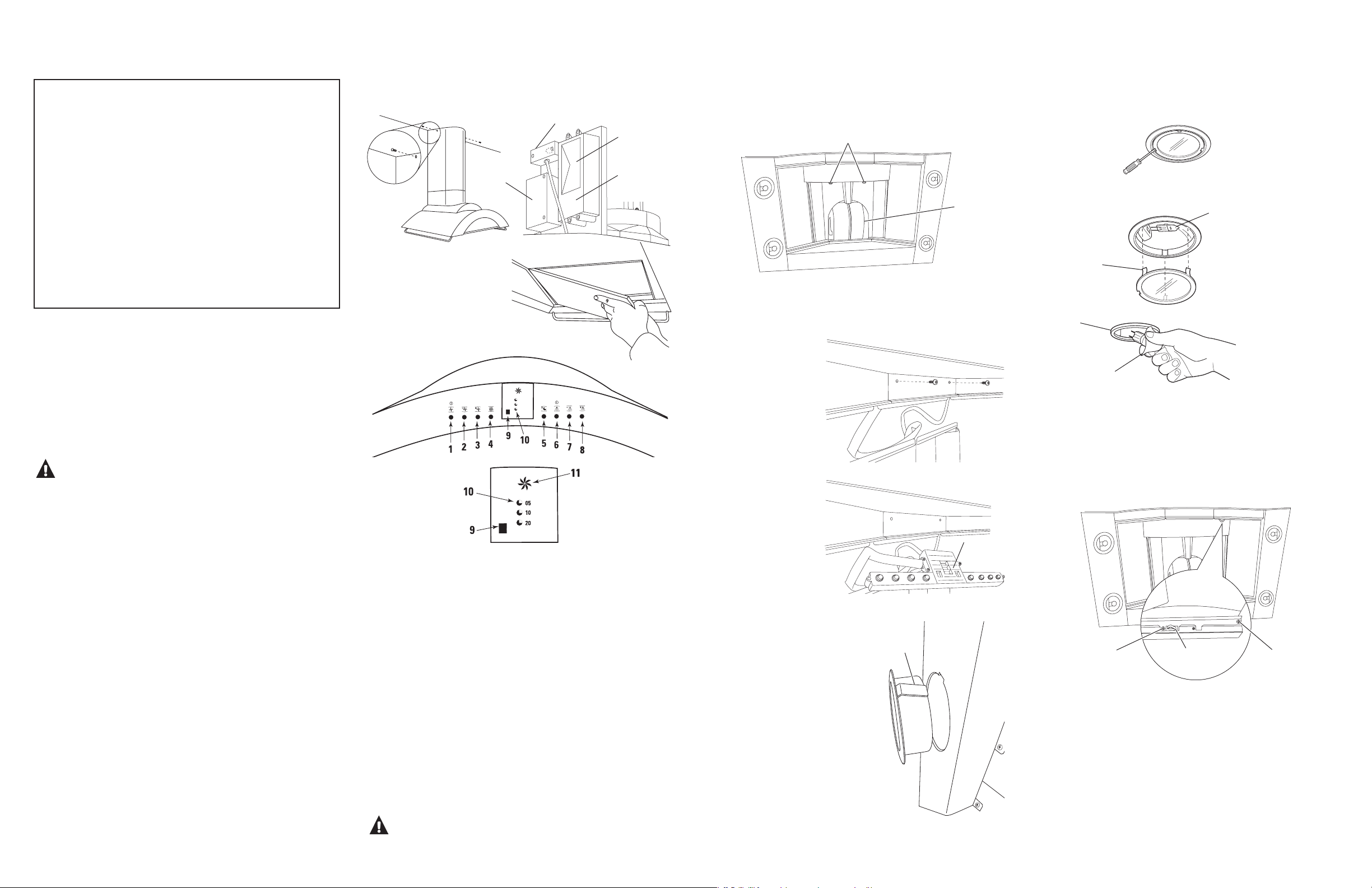

FILTER MICROSWITCH

A microswitch is mounted in the lter channel on the right side. It

senses when lters are removed. The red display light glows when

the lter is removed, if the lter is not making contact with the switch,

or after 30 hours of fan operation to remind the user to clean the

lters. Make sure the lter is seated properly when installed and the

lter light is not on.

TO REMOVE AND REPLACE FILTER MICROSWITCH

Remove 2 screws and lift out the switch. The harness is connected

to the PCB assembly. Refer to the schematic to locate and

disconnect the control CN7.

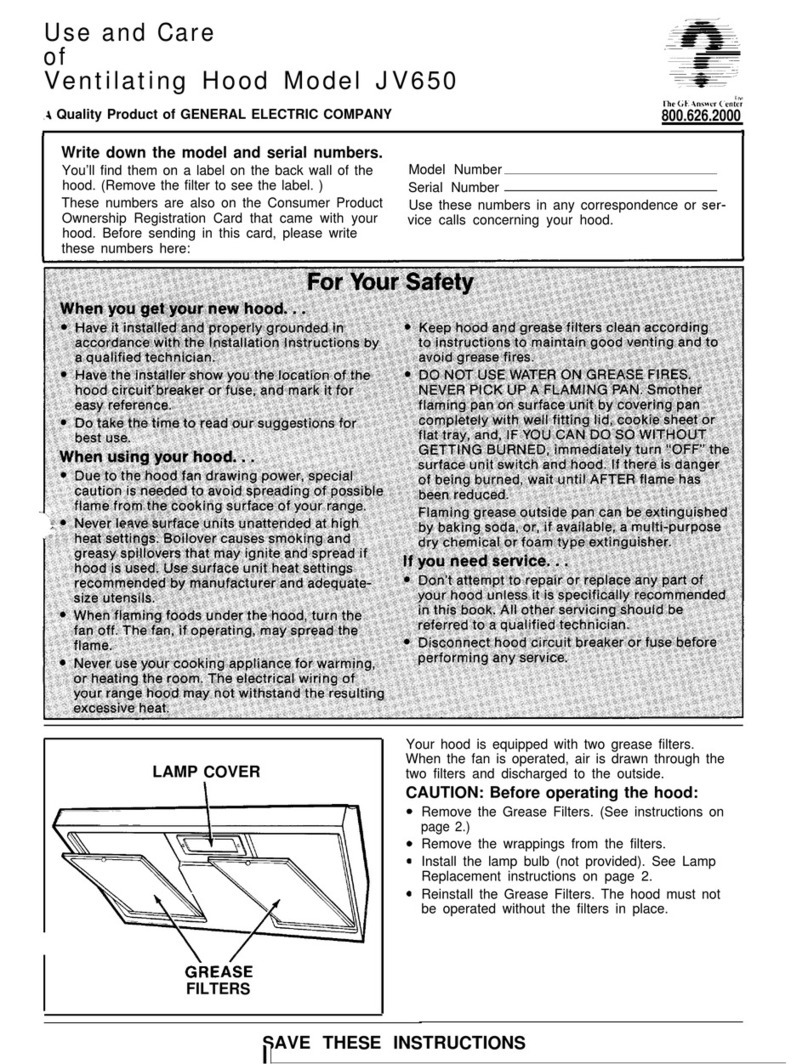

ACCESS TO LIGHTING,

BLOWER AND WIRING

1. Remove metal grease lters.

2. Remove charcoal lters

(if present).

TO ACCESS THE USER INTERFACE ASSEMBLY

Remove 2 thumbscrews holding the control bracket plate. Remove

the plate.

Remove 2 screws that

secure the control behind

the front glass.

Remove the interface

assembly by unplugging

the ribbon harness

connector from the

control PCB.

IMPORTANT: Before

replacing the assembly,

check the operation of the

hood by plugging the new

User Interface Assembly

cable into connector

CNII on the Control PCB.

If the unit does not work,

replace the control board

rst and then recheck

whether the existing user

interface assembly is OK.

Reverse these steps to

reinstall the User Interface

Assembly.

TO REPLACE A HALOGEN LAMP

ASSEMBLY

Reach inside the chassis and press

with ngers against the metal spring

clips. Pull the lamp assembly out

and disconnect the wire connector.

TO ACCESS ELECTRICAL COMPONENTS:

1. Remove two screws from top duct cover at ceiling and slide top

cover down.

2. Lift and remove both duct covers. Set covers aside.

USER INTERFACE ASSEMBLY

The replacement assembly has three PCBs mounted in a plastic

enclosure with eight push buttons and a ribbon cable with ferrite

bead looped through the other end of the cable ribbon. It consists

of the Fan Touch Control PCB, Lamp Touch Control PCB and the

Display PCB.

CAUTION: Components are electrically HOT on

the electronic control when voltage is connected to the hood.

Junction box

Service

manual

Bulb

Tab

Use gloves

or cloth

Receptacle Use a new 120-volt,

25-watt halogen lamp

with a G-9 base. Do

not substitute other

lamps.

Replace lens cover. Make sure the tabs are inserted into the slots.

Removable inner

lamp lens cover

Outer trim ring

(lamp assembly)

Do not remove

Use a small at-blade screwdriver to remove the lamp lens cover.

Spring

clips

Remove 2 thumbscrews

Fan motor

Filter microswitch Remove screwRemove screw

05-09 JR

PCB

Capacitor

User

Interface

Assembly