49-80520-7 9

ADVANCE PLANNING

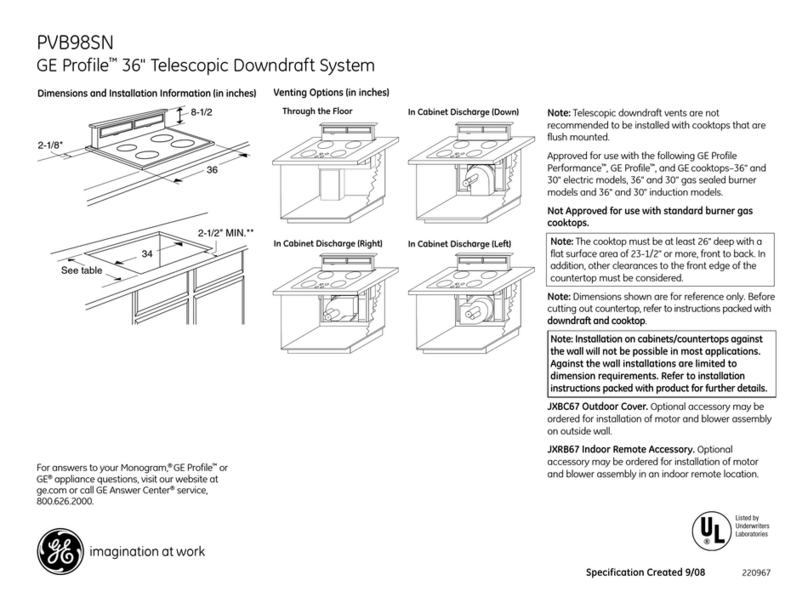

Duct Install Planning

• This hood may be vented vertically through upper cabinets,

soffit or ceiling. A duct transition piece is supplied for vertical

H[KDXVW8VHORFDOO\VXSSOLHGHOERZVWRYHQWKRUL]RQWDOO\

through the rear wall.

• Use metal ductwork only.

'HWHUPLQHWKHH[DFWORFDWLRQRIWKHYHQWKRRG

3ODQWKHURXWHIRUYHQWLQJH[KDXVWWRWKHRXWGRRUV7R

PD[LPL]HWKHYHQWLODWLRQSHUIRUPDQFHRIWKHYHQWV\VWHP

1. Minimize the duct run length and number of transitions

and elbows.

2. Maintain a constant duct size.

3. Seal all joints with duct tape to prevent any leaks.

'RQRWXVHDQ\W\SHRIIOH[LEOHGXFWLQJ

• Use the shortest and straightest duct route possible.

,QVWDOODZDOOFDSRUURRIFDSZLWKGDPSHUDWWKHH[WHULRU

opening. Order the wall or roof cap and any transition

needed in advance.

• When applicable, install any makeup (replacement) air

system in accordance with local building code requirements.

Visit GEAppliances.com for available makeup air solutions.

Wall Framing for Adequate Support

• This vent hood is heavy. Adequate structural support must

be provided. The hood must be secured to vertical studs in

the wall. See page 14.

• We strongly recommend that the vent hood with duct cover

be on site before final framing and wall finishing. This will

also help to accurately locate the ductwork and electrical

service.

POWER SUPPLY

IMPORTANT -(Please read carefully)

WARNING:

FORPERSONAL SAFETY, THISAPPLIANCE MUSTBEPROPERLY

GROUNDED.

Removehouse fuse oropen circuitbreakerbefore beginning

installation.

'RQRWXVHDQH[WHQVLRQFRUGRUDGDSWHUSOXJZLWKWKLV

appliance.Follow National electricalcodes orprevailinglocal

codesand ordinances.

Electrical supply

Thisvent hood mustbe suppliedwith120V, 60 Hz,and

connectedto an individual,properly groundedbranchcircuit,

andprotected by a15 or20amp circuit breakerortime delay

fuse.

• Wiringmust be 2wire withground.

• Ifthe electrical supplydoes notmeetthe above

requirements,call a licensedelectrician beforeproceeding.

• Routehouse wiring asclose totheinstallation location as

possiblein the ceiling,soffit orwall.See page 13fordetails.

• Connectthe wiring tothe housewiringin accordance with

localcodes.

Grounding instructions

Thegrounding conductor mustbe connectedtoa ground

metal,permanent wiring system,or anequipment-grounding

terminalor lead onthe hood.

WARNING: The improperconnection of the

equipment-groundingconductor can resultin a riskofelectric shock.

Checkwith a qualifiedelectrician orservicerepresentativeif you are

indoubt whether theappliance isproperlygrounded..

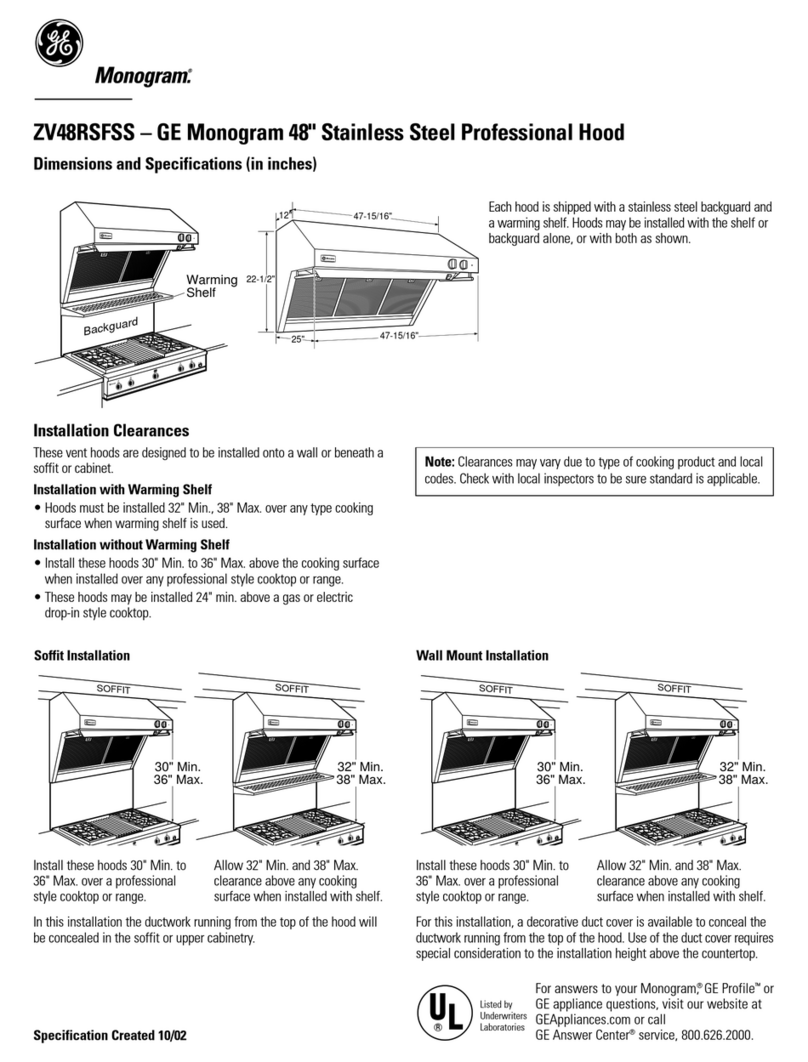

DECORATIVE DUCT COVERS

Adecorative duct coveris availableto fit bothmodelwidths.

Theduct cover concealsthe ductworkrunningfrom the topof

thehood to theceiling orsoffit.The duct coverwillfit 8 ft.to10

ft.ceiling heights. Seepage 12fordetails.

Installation Instructions