849-80549-2

Installation Preparation

PREPARE TO INSTALL THE HOOD

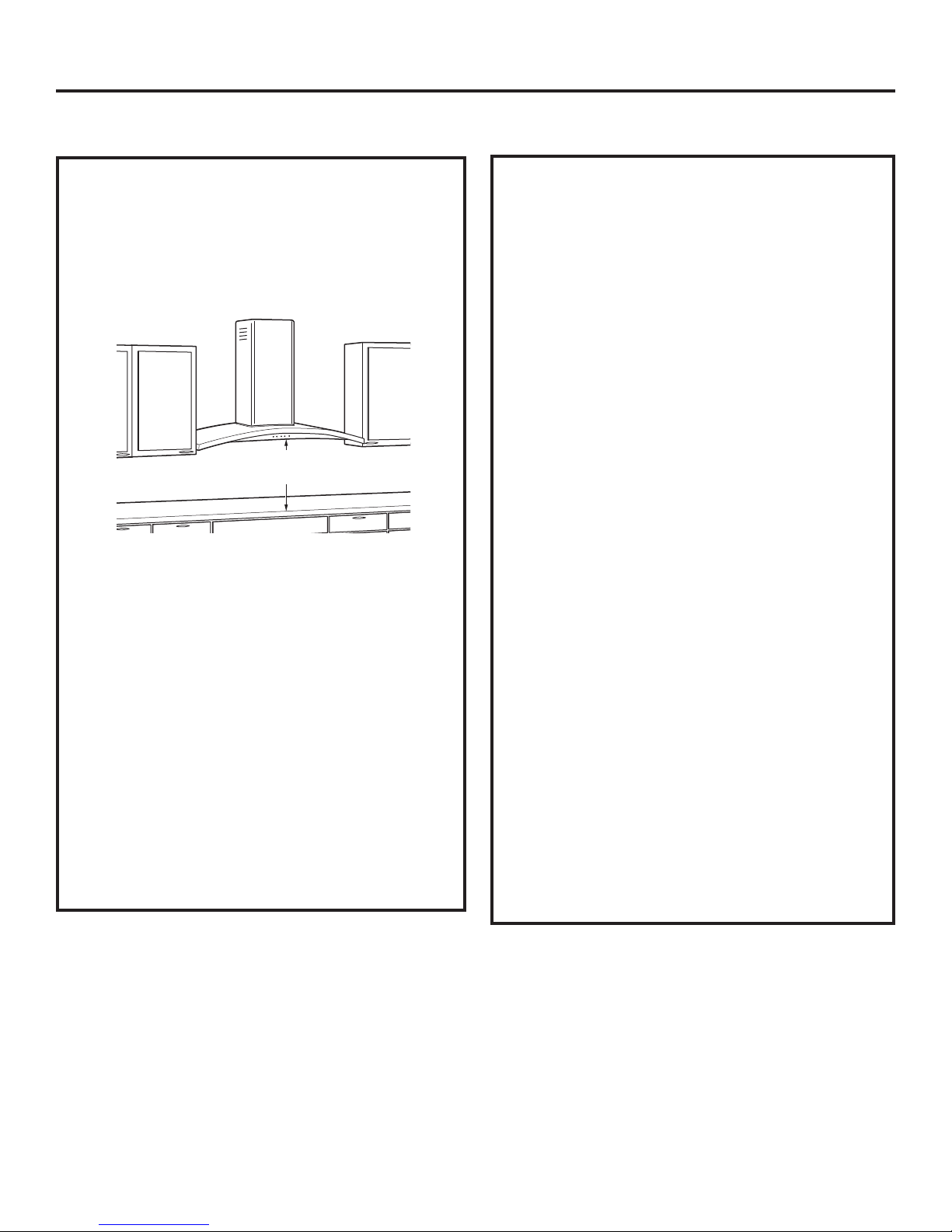

INSTALLATION CLEARANCES

These vent hoods are designed to be installed onto

a wall. They may be installed beneath a soffit or

cabinet.

,QVWDOOWKHVHKRRGVµ0LQWRµ0D[DERYHWKH

cooking surface.

The vent hood must be installed 24” min. and

µPD[DERYHWKHFRRNLQJVXUIDFH7KHKRRG

installation height above the cooking surface

depends upon ceiling height and duct cover

limitations. The telescopic duct cover conceals the

ductwork running from the top of the hood to the

ceiling. For supplied duct cover ceiling heights, see

table on page 13.

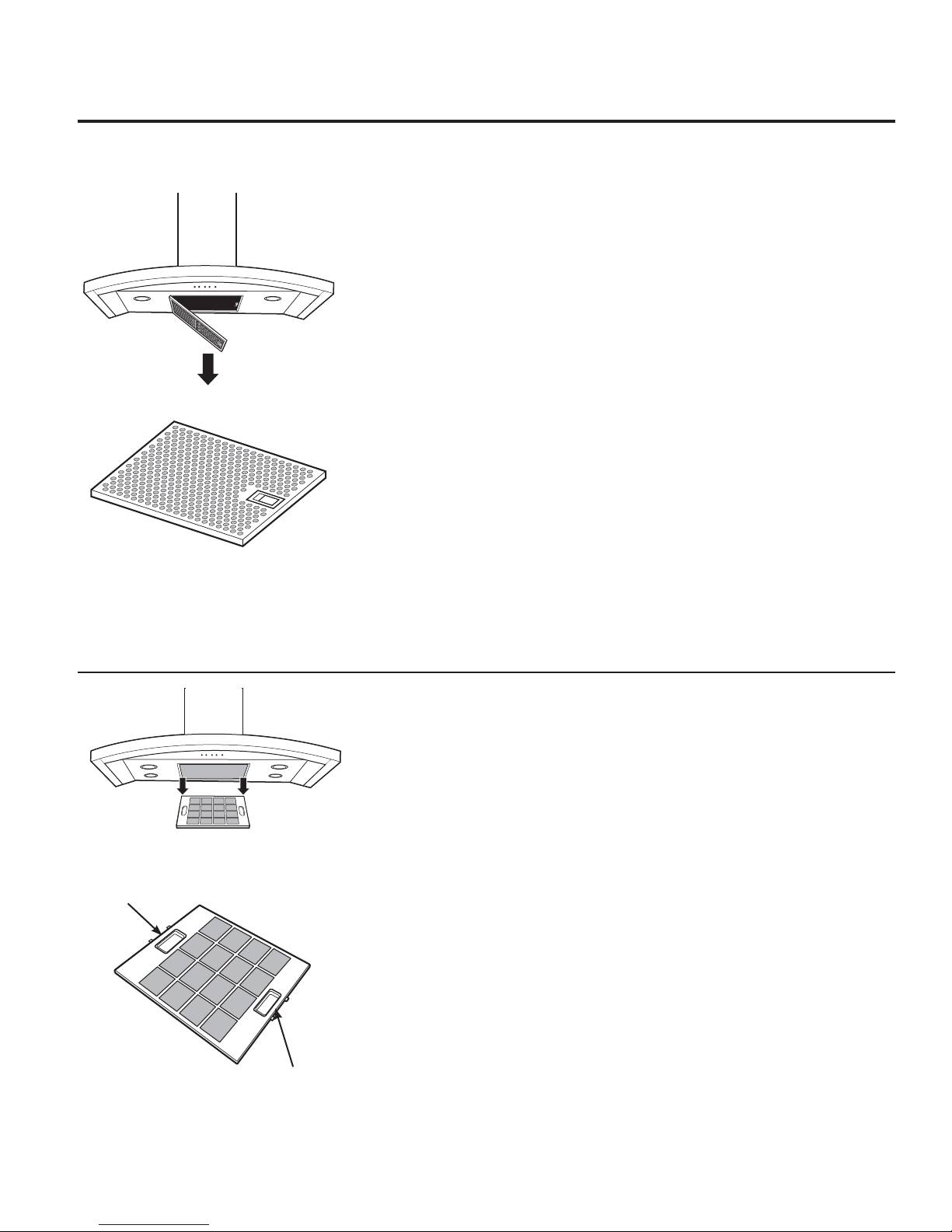

5HFLUFXODWLRQ.LW

Kit includes 1 air deflector and 1 charcoal filter and

is included with the hood.

NOTE: Installation height should be measured

from the cooking surface to the lowest part of the

hood. This hood may be installed onto a wall and

vented to the outdoors, or it can be installed for

recirculating operation. For recirculation operation,

a Recirculating Kit (included) is required.

24” Min.

µ0D[

ADVANCE PLANNING

Ductwork Planning

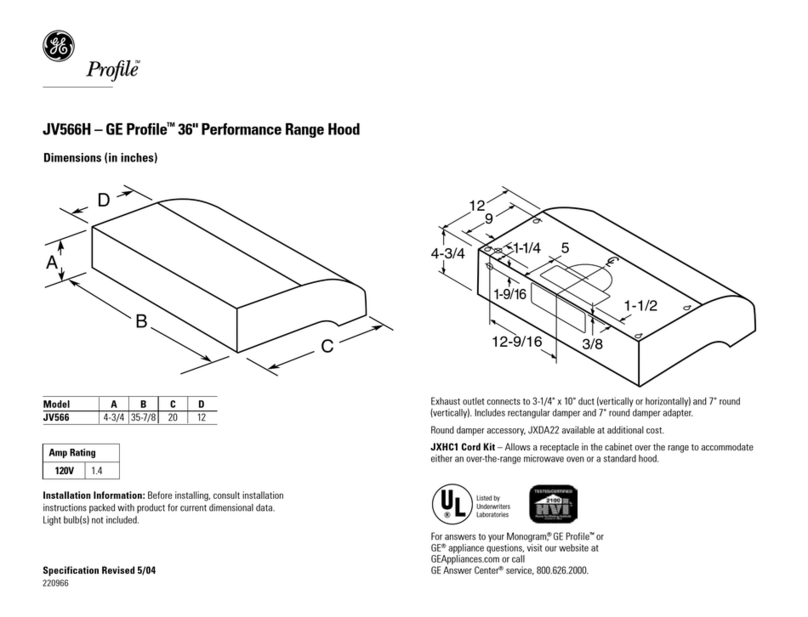

• This hood is designed to be vented vertically

through the ceiling. A duct transition piece is

VXSSOLHGIRUYHUWLFDOH[KDXVW8VHORFDOO\VXSSOLHG

elbows to vent horizontally through the rear wall.

See page 10.

'HWHUPLQHWKHH[DFWORFDWLRQRIWKHYHQWKRRG

• 3ODQWKHURXWHIRUYHQWLQJH[KDXVWWRWKHRXWGRRUV

• Use the shortest and straightest duct route

possible. For satisfactory performance, duct run

VKRXOGQRWH[FHHG·HTXLYDOHQWOHQJWKIRUDQ\

duct configurations.

• Refer to “Duct Fittings” chart to compute the

PD[LPXPSHUPLVVLEOHOHQJWKIRUGXFWUXQVWRWKH

outdoors.

• Use metal ductwork only.

• A transition piece for 8” round duct is supplied.

Use 8” round duct.

• Install a wall cap or roof cap with damper at

WKHH[WHULRURSHQLQJ2UGHUWKHZDOORUURRIFDS

and any transition and length of duct needed in

advance.

• When applicable, install any makeup (replacement)

air system in accordance with local building code

requirements. Visit GEAppliances.com for available

makeup air solutions.

Wall Framing for Adequate Support

• This vent hood is heavy. Adequate structural

support must be provided. The hood must be

secured to vertical studs in the wall. See page 14.

• We strongly recommend that the vent hood with

duct cover be on site before final framing and

wall finishing. This will also help to accurately

locate the ductwork and electrical service.