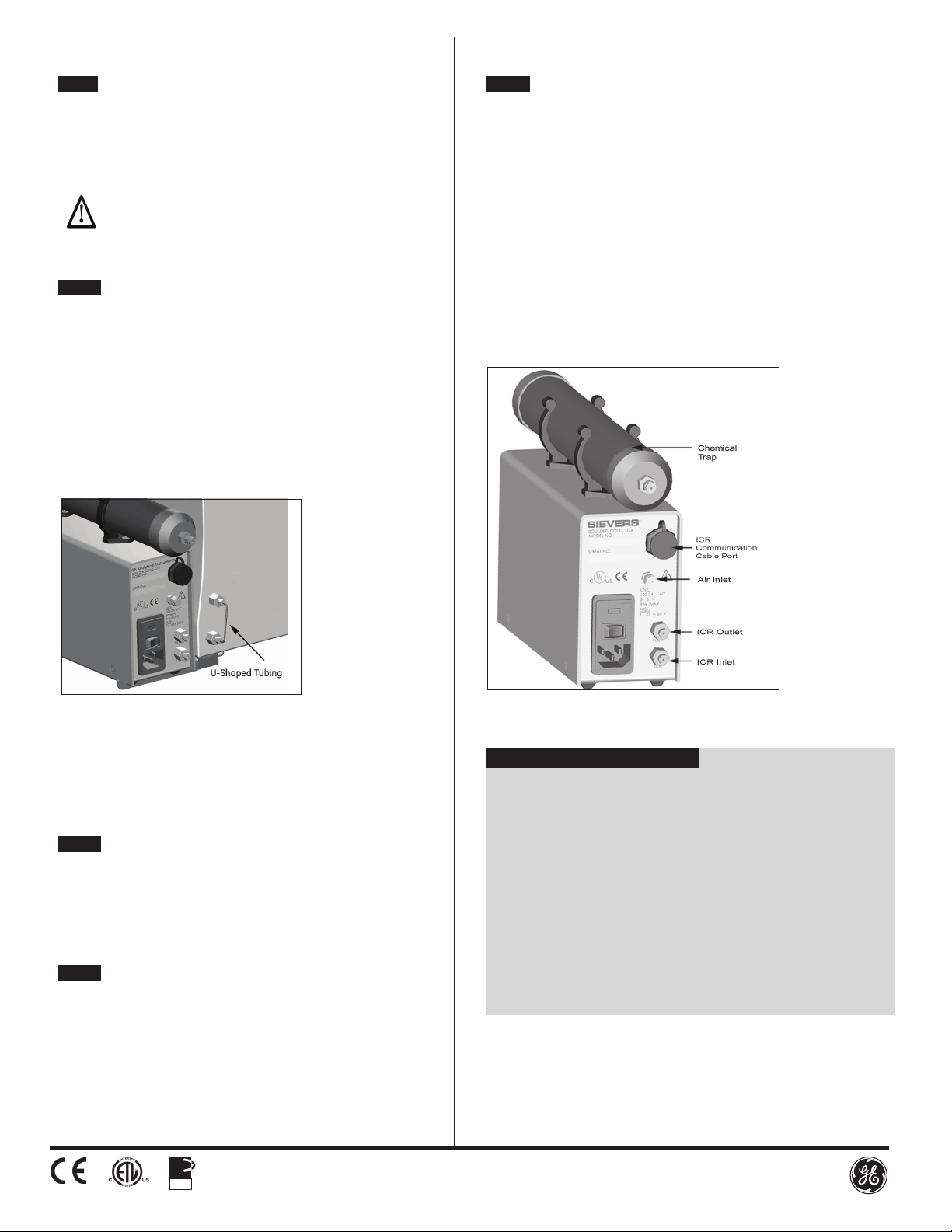

Abbildung 3. Entfernen des U-förmigen Rohrstücks

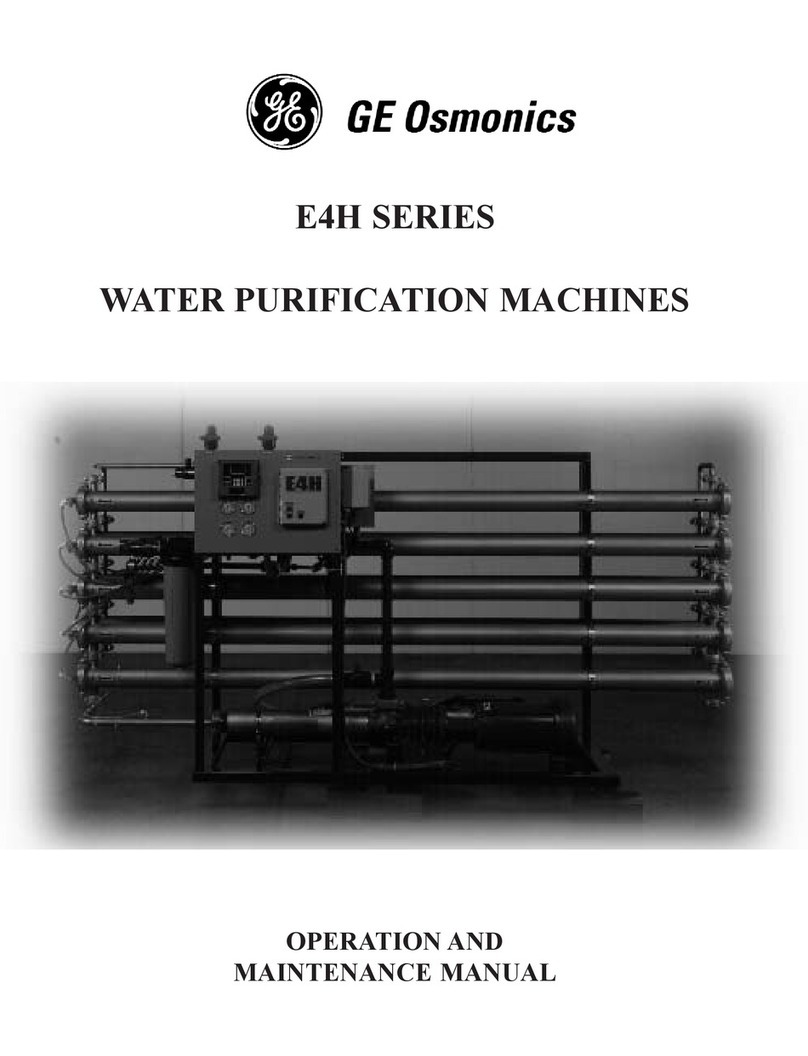

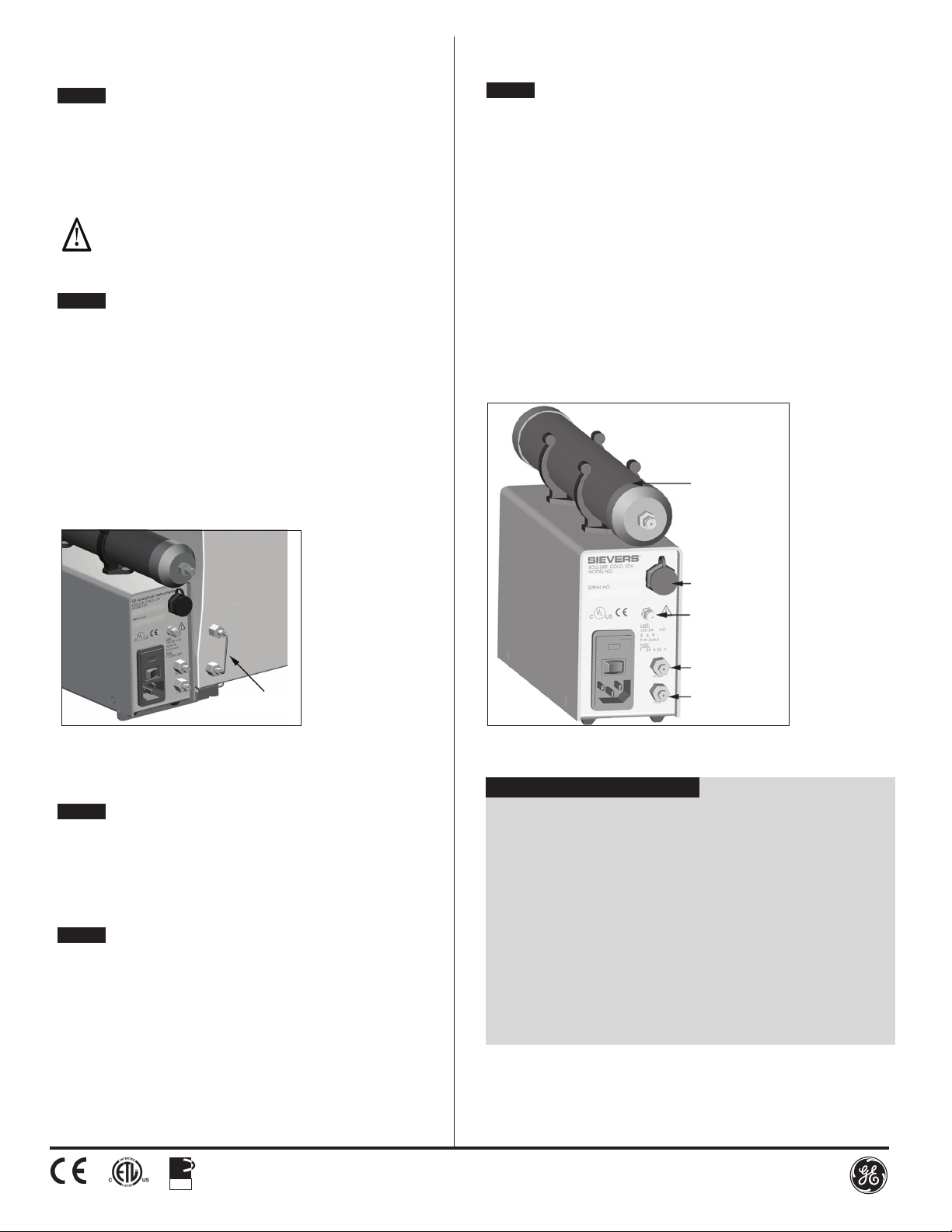

Abbildung 4. Rückansicht des Sievers 900 ICR

Schritt 5 Montieren der ICR-Halterung am Analysator

1. Befestigen Sie die große Montagehalterung, die jetzt am ICR montiert ist, an

der kleinen Montagehalterung.

2. Schieben Sie die große Halterung über die kleine Halterung und

befestigen Sie die Baugruppe, indem Sie die beiden unverlierbaren

Kreuzschlitzstellschrauben festziehen.

_________________________________________________________

HINWEIS: Die ICR-Montagehalterung kann NUR rechts am Analysator

befestigt werden.

Stellen Sie den ICR nicht in der Nähe einer Wärmequelle oder eines

Warmluftauslasses auf.

_________________________________________________________

Schritt 6 Montieren der Probenanschlüsse

Zur Herstellung des Probenusses vom Analysator in den ICR und vom ICR

zurück zum Analysator müssen die Probenanschlüsse montiert werden.

Dies ist eine gesonderte Anweisung in der Betriebs- und Wartungsanleitung des

Analysators unter "Probeneinlasssystem anschließen". Beide Verfahren MÜSSEN

ausgeführt worden sein, bevor der ICR mit dem Analysator in betrieb genommen

werden kann.

1. Halten Sie die Schläuche aus dem ICR-Zubehörkit für dieses Verfahren bereit.

2. Machen Sie sich an der Rückseite des Analysators die mit "Vom ICR" (From

ICR) und "Zum ICR" (To ICR) bezeichneten Ports ausndig. Entfernen Sie das

U-förmige Edelstahl-Rohrstück, indem Sie die Valco-Armaturen mit einem

¼"-Gabelschlüssel lösen (siehe Abbildung 3).

3. Verbinden Sie mit dem Schlauch den mit "Auslass" (Outlet) bezeichneten ICR-

Port mit dem mit "Vom ICR" (From ICR) bezeichneten Analysator-Port. Ziehen

Sie die Valco-Armatur mit einem ¼"-Gabelschlüssel fest.

4. Verbinden Sie mit dem Schlauch den mit "Einlass" (Inlet) bezeichneten ICR-Port

mit dem mit "Zum ICR" (To ICR) bezeichneten Analysator-Port. Ziehen Sie die

Valco-Armatur mit einem ¼"-Gabelschlüssel fest.

Schritt 7 Montieren der elektrischen Anschlüsse

Montieren Sie das ICR-Kommunikationskabel und das AC-Netzkabel am ICR.

1. Schließen Sie ein Ende des ICR-Kommunikationskabels am ICR und das

andere Ende am Analysator an. Eventuell sind an beiden Geräten die

Anschlussabdeckungen zu entfernen, bevor das Kabel montiert werden kann.

2. Schließen Sie das AC-Netzkabel auf der Rückseite des ICRs und mit dem

anderen Ende an einer geerdeten Stromversorgung an.

Schritt 8 Vorbereiten der chemischen Falle

Wenn eine chemische Falle am ICR montiert werden soll, wird der im ICR-

Zubehörkit enthaltene Schlauchsatz benötigt.

1. Halten Sie den Lufteinlassschlauch aus dem ICR-Zubehörkit bereit.

2. Mit dem Schlauch verbinden Sie die chemische Falle mit dem ICR, indem

Sie die Messing-Muttern an jedem Ende des Schlauchs mit einem

5/16"-Gabelschlüssel festziehen.

3. Entfernen Sie den Verschluss (John Guest-Armatur) vorne von der chemischen

Falle, indem Sie die schwarze Basis mit einer Hand nach innen drücken und

die rote Armatur mit der anderen Hand herausziehen.

ISO

9001:2008

QUALITY

MANAGEMENT

SYSTEM

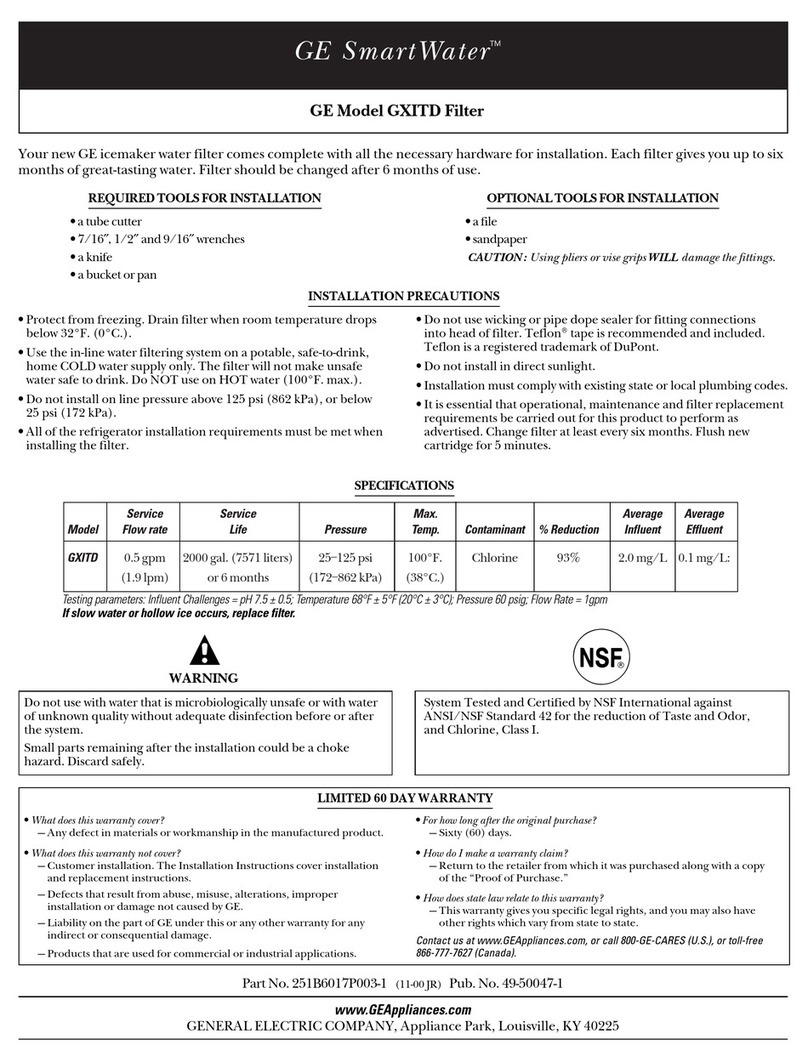

Spezikationen

Leistungsbedarf (100-240) ± 10% VAC, 50/60 Hz, 9 Watt

Sicherungen 0,25 A, 250 V SloBlo (5 X 20 mm)

Umgebungstemperatur 50-104 °F (10 - 40 °C)

Relative Luftfeuchte bis zu 95%, nichtkondensierend

Maximale Höhe 3.000 m (9.843 ft)

Installation/Überspannungskategorie II

Verschmutzungsgrad 2

Abmessungen (Höhe x Breite x Tiefe) 12,2 cm x 8,2 cm x 33,4 cm

(4,8 " x 3,2" x 13,1")

Gewicht 2,6 kg (5,75 lbs.)

Sicherheitszertikate CE, ETL-gelistet. Erfüllt UL-Standard

61010-1, zertiziert nach

CSA C22.2 No. 61010-1.

Schritt 9 Abschließendes Einrichten

1. Vergewissen Sie sich, dass das Probeneinlasssystem am Analysator angeschlossen

ist. Schlagen Sie bei Bedarf in der Betriebs- und Wartungsanleitung des Analysators

nach.

2. Wenn Sie den ICR in Verbindung mit einem tragbaren Analysator verwenden wollen,

montieren Sie den Schlauchführungsclip auf der Rückseite des Analysators und

führen Sie dann das Kommunikationskabel durch den Clip. Der Clip sichert das

Kommunikationskabel, wenn der Analysator mit dem an der Halterung montierten

ICR getragen wird.

3. Etablieren Sie einen Zuuss von Probenwasser, wenn der Analysator als kontinuierlicher

Probendurchuss angeschlossen ist.

4. Schalten Sie den Analysator ein.

5. Schalten Sie den ICR ein.

6. Legen Sie zum Starten des ICR-Betriebs den ICR-Schalter in Inline-Stellung.

7. Wenn Sie manuelle Einstellungen für die Reagenzien-Durchussrate verwenden

möchten, stellen Sie die Durchussrate entsprechend für den Gebrauch mit ICR ein.

Anweisungen benden sich in der Betriebs- und Wartungsanleitung des ICRs unter

"Einstellen der Reagenzien-Durchussraten".

Chemische Falle

Anschluss ICR-

Kommunikationskabel

Lufteinlass

ICR-Auslass (Outlet)

ICR-Einlass (Inlet)