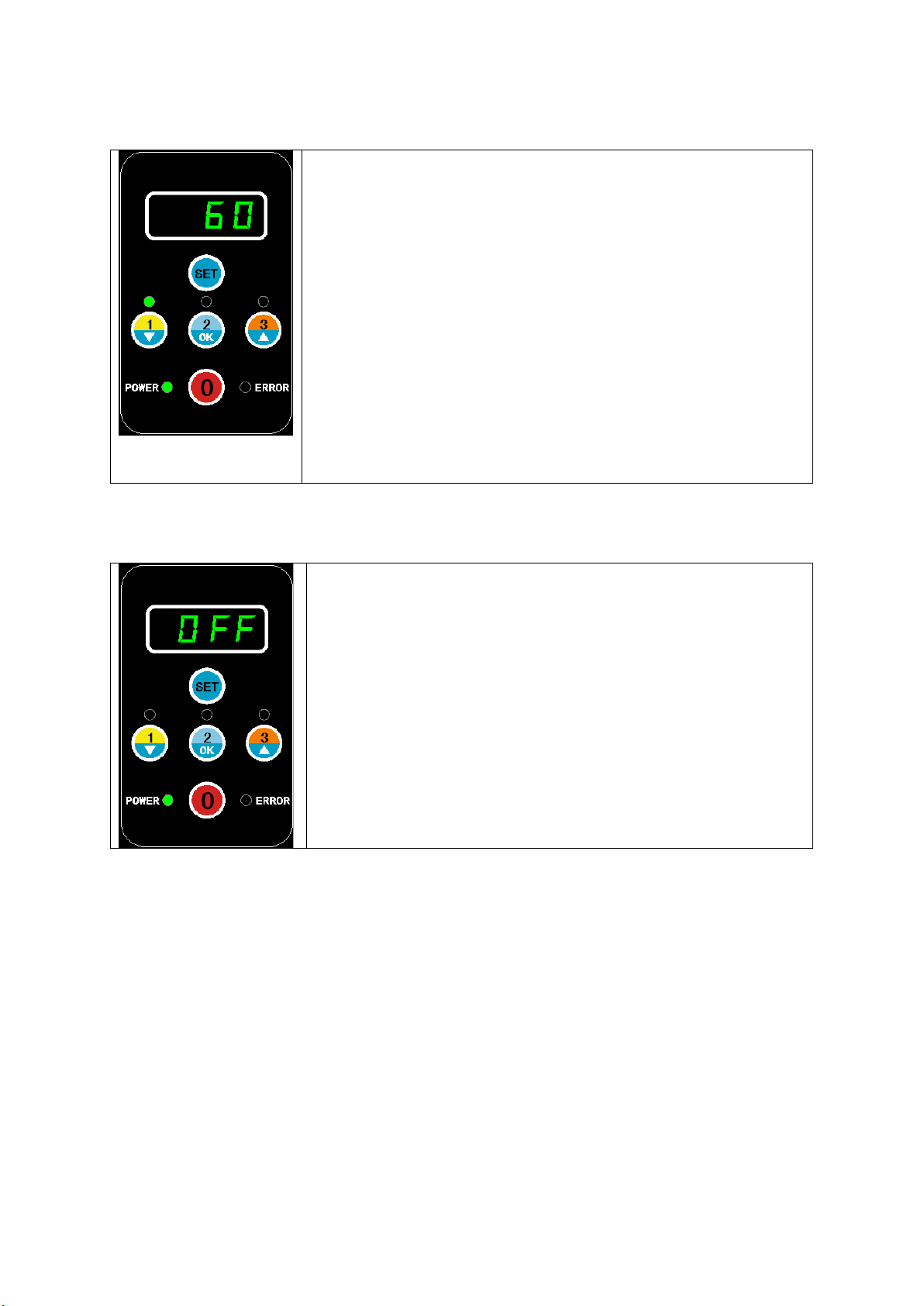

In case of an error occurs, the Error light turns on and the LED

window displays an error code. The message will not be cleared

until the fault is disappeared or the power supply is turned off.

The controller records the latest 8 errors, and the error history

can be viewed one by one in the LED window. When a new error

occurs, the oldest error record will be deleted.

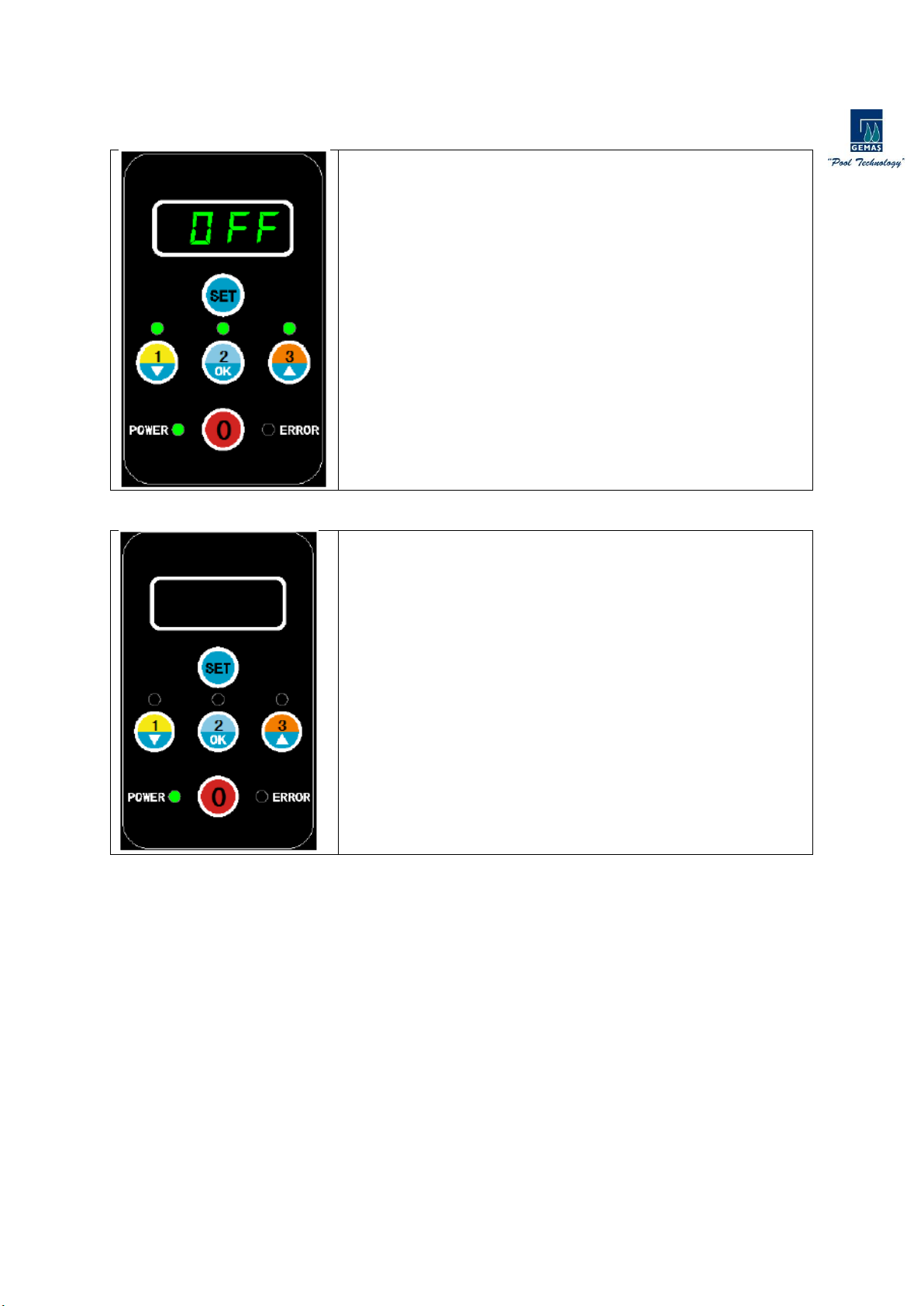

To view the error records, press the “0” button first and then

soon press the “SET” button within 500msec at standby state.

Press the “▲”button to go to the next error code. Press the “▼”

button to delete the current error record, and press the “▼”

button for at least 3sec to delete all error records. Pressing the

“SET” button or doing nothing within 30sec will exit the error

code view mode.

The first character “E” denotes “Error”, the second digit shows

the sequence of the error, and the last two digits are the error

code.