Service Instructions

The SEAGULL®IV X-6 Purification System, furnished with General Ecology, Inc.’s RS-6SG Cartridge

Module, should require little or no service other than an occasional Module replacement.The need for

changing the Module will be apparent from an obviously reduced flow rate due to clogging. Service should be

accomplished by the following procedure.

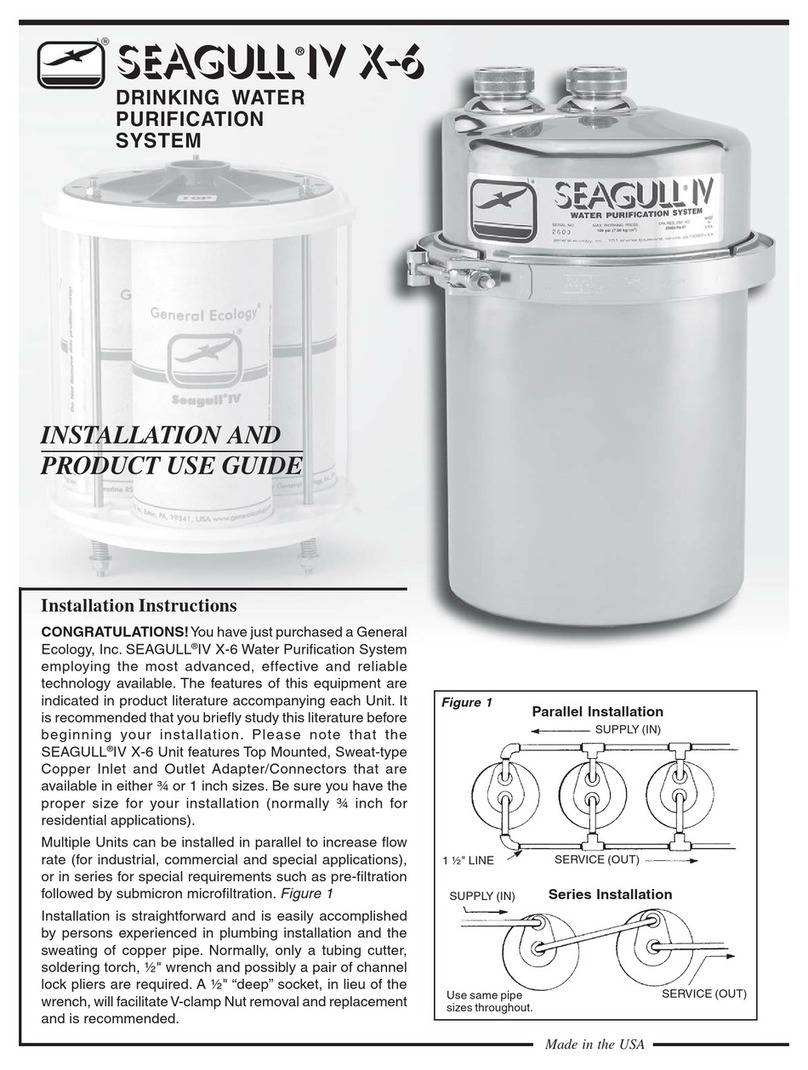

IMPORTANT: In order to avoid reinstalling the Unit in the reverse direction, the Inlet and Outlet Pipes should

be labeled prior to disconnecting the unit. On all General Ecology stainless steel Pressure Vessels, the

Port closest to the Vessel Cover’s side is the Supply (INLET) Port and the center Port is the Service

(OUTLET) Port.

Disassembly

Removing Module from Unit:

1. Close supply, open downstream valve or faucet to

relieve pressure, then close service line valves. Loosen

Closure Nuts and gradually remove Dielectric

Positioning Pads to lower Unit to supporting surface.

2. Place Unit over drain or a container to catch excess

water as the V-clamp is removed, and remove V-clamp.

3. Carefully raise the Cover from the Unit and remove the

Cartridge Module. (We recommend the use of rubber

gloves to protect the skin from direct contact with the

potential concentration of impurities that may be on the

outside of the Cartridge Module.) Dump excess water

from the Bowl and rinse clean. Be careful not to dent or

cut the Bowl Flange, nor cut, nor allow dirt on any of

the Gaskets.

4. Be sure the Rubber Pedestal is properly in place on the

raised center of the Bowl bottom.

5. Be sure Gaskets are clean and free of cuts and other

potential leak paths.

6. For ease of installation look inside of cover for center

port O-rings and apply a light coating of petroleum jelly

before aligning and re-inserting the cartridge module.

7. Lower new RS-6SG cartridge module into bowl.

8. Center the Cover on the Module while aligning it with

the Bowl Flange and press down into position.

9. Install V-clamp and tighten (do not over tighten) while

lightly tapping the outside of the V-clamp (not on the

bolt). A light coating of petroleum jelly applied to the

insides of the V segments will ease clamp installation.

Reinstallation

Placing the Unit back in service:

1. Reposition the Unit per initial installation, being careful

to replace the Closure Nut Gaskets properly and to

position the Unit to eliminate strain on the Service and

Supply Lines. Only tighten the Inlet Port Nut at

this time.

2.

Slowly

open the Supply Line Valve allowing water to

enter the Unit.Trapped air will exhaust through the

loosely connected Outlet Port until the Unit fills. When

water starts to flow from the Outlet:

a. Close the Inlet Valve.

b. Snugly tighten the Outlet Closure Nut.

c. Open the Outlet Valve.

d. Reopen the Inlet Valve to place the

SEAGULL®IV X-6 Unit in service.

3. Allow water to run for three to five minutes to remove

air and particles from the new module.

200123A 03/09

©1996, General Ecology, Inc. ®, ™ registered trademarks of General Ecology, IncAll health claims not in accordance with local or state laws are hereby withdrawn. EPA Reg. No. 37403-PA-01

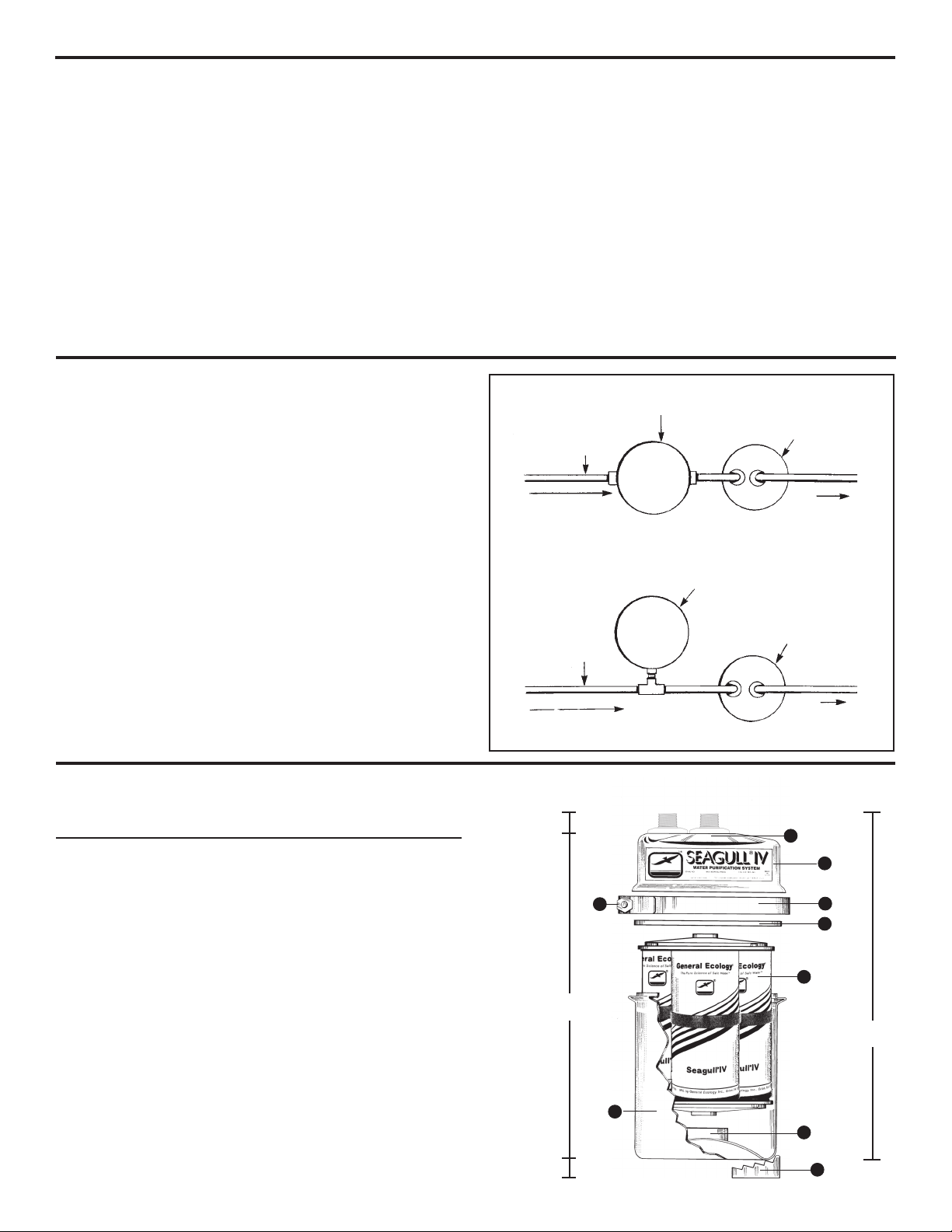

V-CLAMP

MODULE

DIELECTRIC PAD

HOUSING COVER

V-CLAMP NUT

HOUSING BOWL

OUTLET NPT PORT

(610)363-7900-fax(610)363-0412

www.generalecology.com

QUESTIONS?

Call 1-800-441-8166

in USA/Canada

for Customer Service

HOUSING

GASKET

AS9100, ISO 9001 and FAA Quality Certified

Original Equipment and PMA Manufacturer