3

Exclusive Feature — TOP MOUNT FAUCET

Figure 5

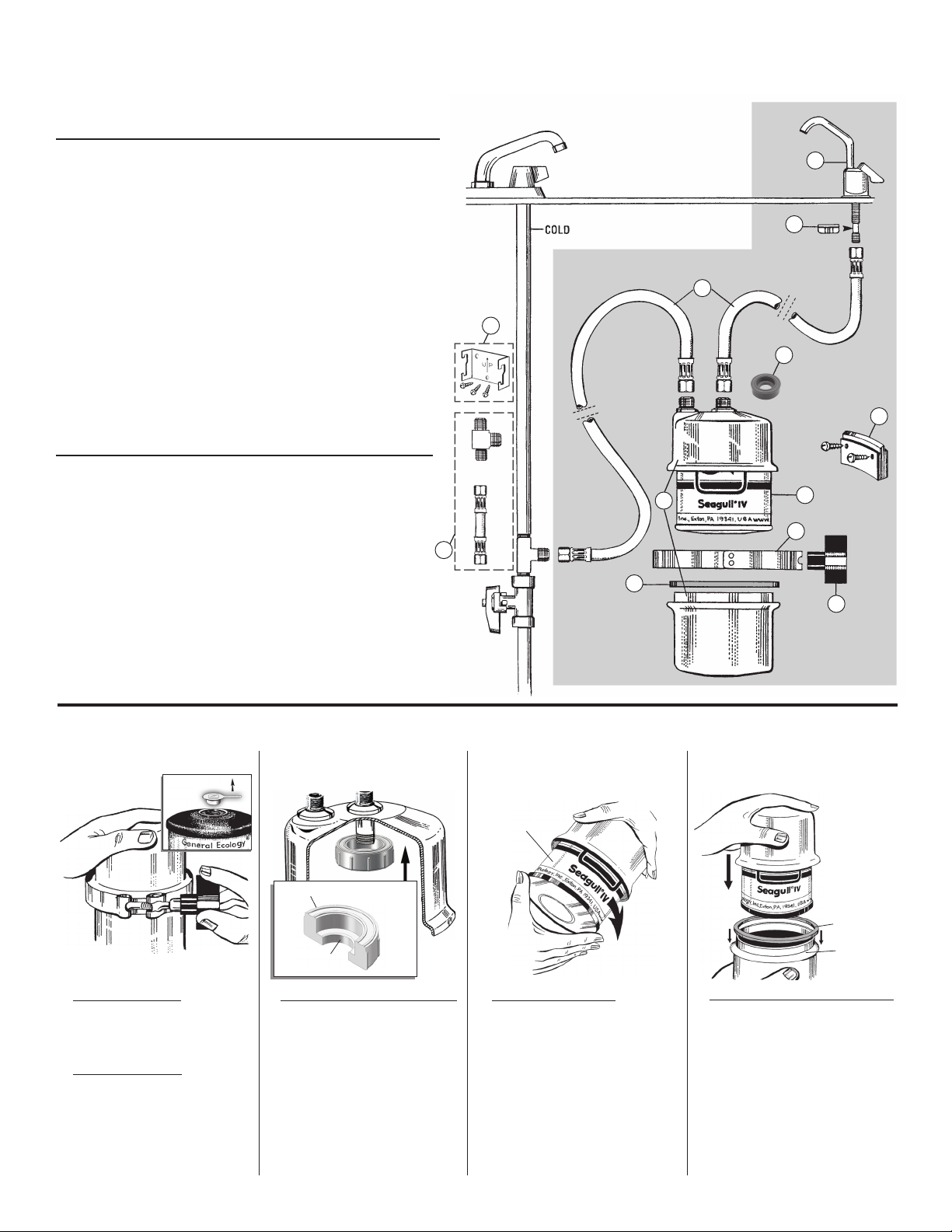

6. Install Mounting Bracket. Position

black Mounting Bracket on the inside

wall of the sink cabinet. Use the two

Self-Tapping Screws to securely install

the Bracket. (figure 4). Make sure the

Bracket location permits access to the

cold water valve location and easy

access for Cartridge changes.

7. Install Faucet. The System is furnished

with General Ecology’s exclusive “Top

Mount” Ceramic Disc Faucet. If a

suitable hole isn’t available, prepare a

¾” hole to install your faucet. Refer to

Mounting Pattern below.

Sinks and counter tops made of

porcelain, stainless steel, stone or man-

made material require special care. We

suggest you consult the manufacturer’s

guidelines or contact your dealer for

best results in drilling the ¾” hole

necessary to mount the faucet. Be sure

sink/counter top surface at drill hole is

flat and burr free.

To change “pull direction” of handle

To change “pull direction” of handle

on faucet, lift handle off stem and

reposition stainless steel pin to

alternate location. Reinstall handle.

Stainless

steel pin

Place Pin on right

or left side

Mounting Hole Pattern

for FP Faucet

.75” (1.9 cm.)

Hole Diameter

1.9” (4.8 cm)

Base Diameter

8. Connect Hose directly to Faucet Stem

and tighten securely by hand. Do not

overtighten. Insert and thread Spout

into base, Do not over tighten (figure

5). Drop free end of Connector Hose

through previously prepared hole and

position Faucet in hole.

Threaded

Spout

Figure 7

9.

Mount Faucet. Slide open side of Faucet

Mounting Nut onto reduced diameter,

un-threaded section of Faucet Stem now

beneath the sink/counter (Fig. 6). Slide

the Nut upwards to contact the threads.

Then carefully engage the threads, being

careful to not cross thread. Hand tighten

as necessary to hold the Faucet in place,

Do not use tools and do not overtighten.

Check alignment and position of Faucet,

and adjust as necessary.

Figure 8

10. Connect Inlet and Outlet lines. Connect

free end of the Hose from Faucet

Stem to Outlet (center) Port on the

Pressure Vessel. Tighten securely. Do

not overtighten. Connect remaining

Hose from fitting on cold water supply

line to Inlet (outside) Port on top of

Pressure Vessel. Do not overtighten.

Inlet Line

connects

to Cold Water

Supply.

Outlet Line

connects to

Water Faucet.

Inlet Line

Outlet Line

11. Mount unit on Bracket by placing the

V-Clamp over the raised section on

top of the Bracket. Open the Faucet to

allow air to exhaust slowly. Open Valve

on cold water service line. Check for

leaks. Allow water to run for several

minutes to clear line and system of air

and any loose materials. Please note

that for the first few days you may see

entrapped air bubbles within the water.

This is perfectly normal and will cease

after the unit has processed several

gallons of water. Also, some black

“fines” from inside of cartridge may

flow with the first few gallons of water.

These are harmless, if consumed.

Figure 9

QUESTIONS?

Visit www.generalecology.com

or Call 1-800-441-8166

for Customer Service

Figure 6