— Product Guide 103.1 — D:9

www.GeneralLock.com

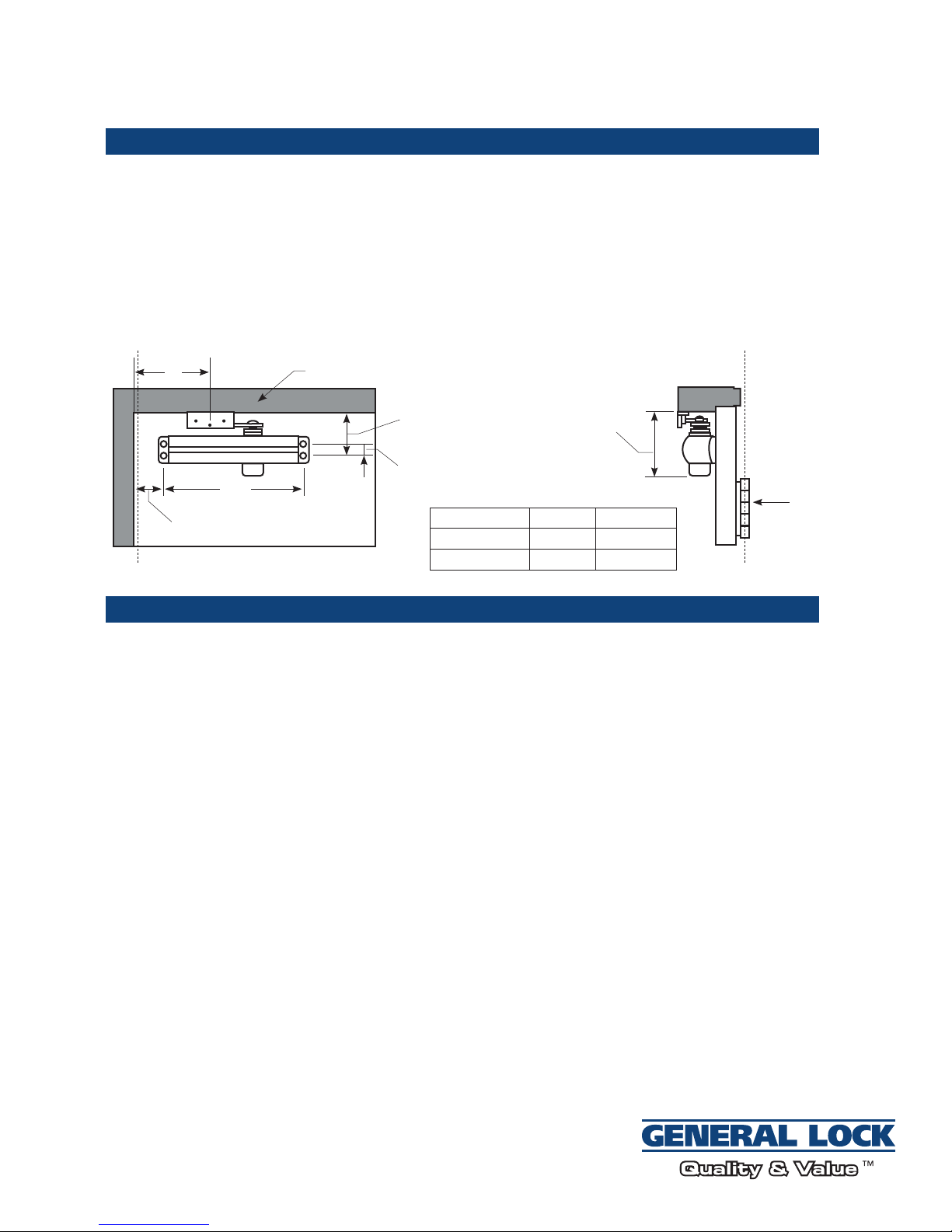

Opening Dim. A Dim. B

To 120º 8-3/4” 3-3/4”

120º and wider 11-1/4” 1-3/4”

C

L

12”

B

5-1/2”

3/4”

4-1/4”

Hinge

Jamb

A

C

L

SPECIFICATIONS:

Closer for interior and exterior door shall be needle-bearing type with a cast aluminum body. Closer

shall be non-handed to permit installation on either side of the door. Closer shall be supplied with a

standard shoe and soffit plate to allow standard, top-jamb, or parallel installation. Closer shall contain

hydraulic fluid that is non-gumming and non-freezing. Door closer shall have two separate, adjustable

regulating valves to control sweeping and latching speeds. Closer shall come standard with backcheck

feature. Closer shall fit into hole patterns 12” in width (two holes on each end) and be supplied with

machine screw and sex nuts and bolts. Closer shall be ANSI 156.4 Grade 1 and UL Listed for use on

labeled fire doors. Closer shall be available with slim or full-size covers.

C7000 Series Door Closer Installation

Parallel Arm Installation and Specifications

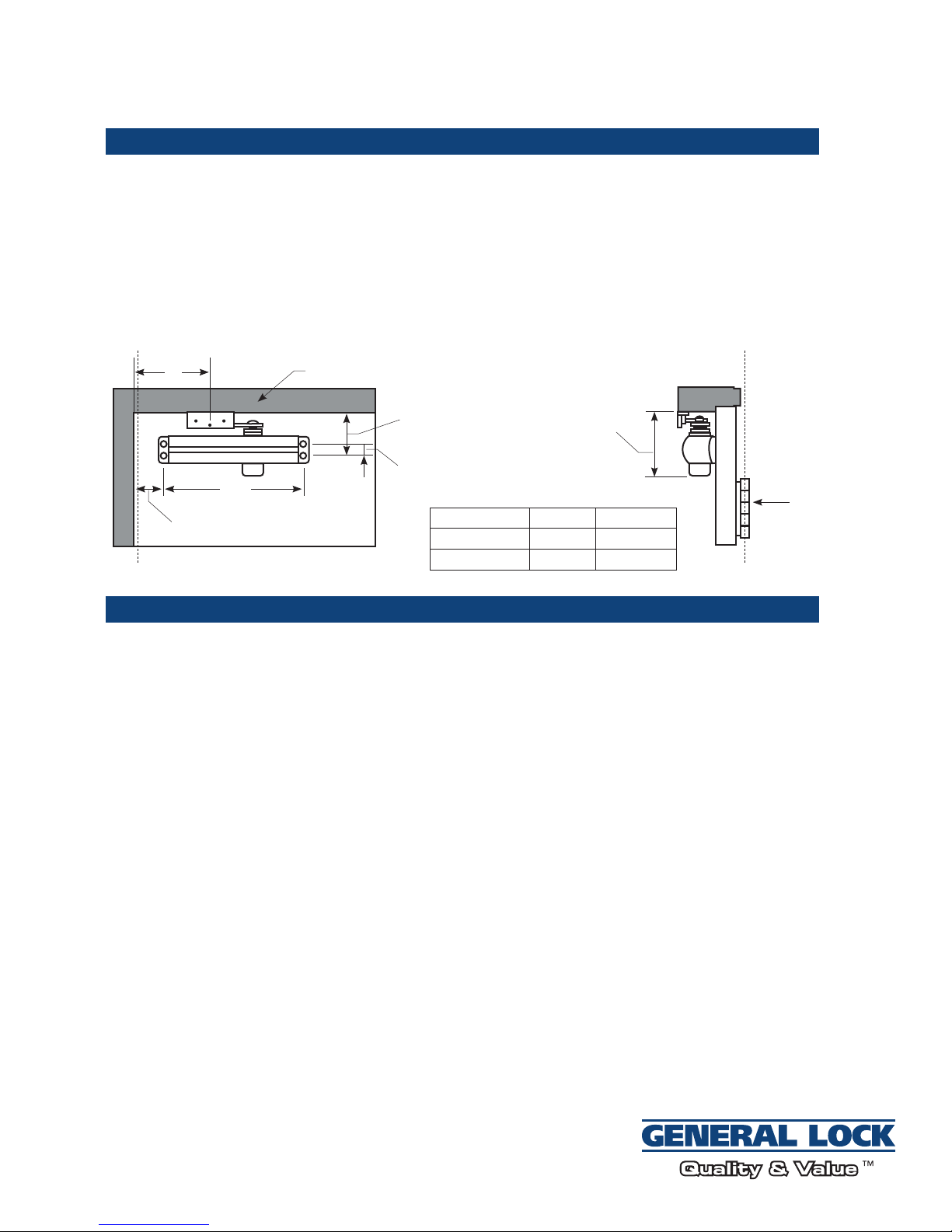

PARALLEL ARM INSTALLATION:

Parallel arm application is the least power efficient. It provides approximately 25% less power than

regular arm. It is installed on the frame stop (push) side of the door. Since it is parallel with the

door, it is chosen for appearances and is least susceptible to vandalism, making it a popular choice

in schools. Parallel arm applications require at least 4-1/2” from the top of the door to the bottom

mounting point of the door closer, or else a drop plate must be used.