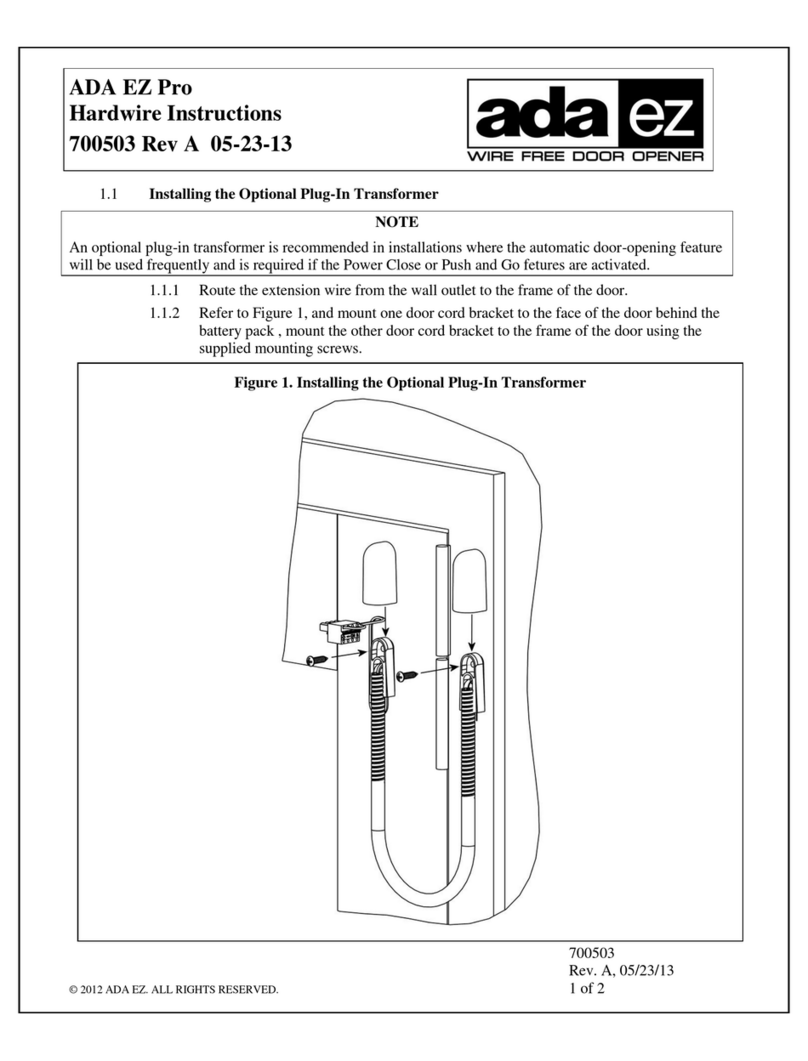

18

The clutch serves to protect the door, the

electric operator and other equipment from

undue stress or damage caused by starting

forces and/or an obstruction to the door. It

should be set NO TIGHTER than is necessary

to smoothly and consistently move the door

throughout its full range of travel. When

properly set, it will slip freely if the door should

encounter an obstruction, and it should be

possible to stop the travel of the door by hand.

WARNING: BEFORE ADJUSTMENT, REMOVE

POWER TO THE OPERATOR!

CAUTION: NEVER COMPRESS CLUTCH SPRING

BEYOND POINT LIMITED BY THE DESIGN

OF THE OPERATOR OR REPLACE IT WITH A

HEAVIER SPRING.

1. Remove cotter pin from slotted hex nut and

clutch shaft.

2. Back o slotted hex nut until there is

insucient tension on clutch spring to

permit clutch to

drive door.

3. Tighten slotted hex nut gradually until there

is just enough tension on spring to permit

operator to move door smoothly, but to

allow clutch to slip if door is obstructed.

4. Be sure cotter pin is reinstalled each time

operator is tested for clutch adjustment

and that it is locked in place upon

completion of adjustment.

Due to changing conditions of the door

and normal wear, it may be necessary to

occasionally re-adjust the clutch to obtain

dependable operation.

WARNING: BEFORE DOING SO, BE CERTAIN THAT

THE DOOR IS IN GOOD WORKING CONDITION,

IS PROPERLY COUNTERBALANCED, AND THAT

THE CLUTCH IS NOT SLIPPING BECAUSE OF

LOOSE OR MISSING HARDWARE, BINDING IN

THE TRACK, RUBBING AGAINST THE DOOR STOPS, OR DEFECTIVE OR MISADJUSTED SPRINGS. ANY

SERVICE REQUIRED TO THE DOOR, DOOR SPRINGS OR DOOR OPERATOR MUST BE PERFORMED BY A

QUALIFIED PROFESSIONAL DOOR INSTALLER.

The clutch pad will wear during normal operation and should be replaced when it becomes

dicult or impossible to suciently tighten the clutch to obtain smooth operation of the

door when it is in good working condition. To replace the clutch pad, rst loosen the motor

mounting bolts and remove the V-belt, followed by the clutch adjusting nuts, spring and

clutch pulley. Check condition of V-belt before reassembly and replace if required.

RISK OF ENTRAPMENT THAT MAY

RESULT IN SEVERE INJURY OR DEATH!

DISCONNECT POWER TO THE OPERATOR

BEFORE SERVICING OR MAKING

ADJUSTMENTS. ENSURE DOORWAY

IS CLEAR BEFORE STARTING TESTING

OF UNIT.

WARNING

ALWAYS DISCONNECT POWER TO

THE OPERATOR BEFORE SERVICING,

CONNECTING ACCESSORY DEVICES

OR MAKING ADJUSTMENTS.

CAUTION

CLUTCH ADJUSTMENT

OPERATION AND ADJUSTMENT INSTRUCTIONS

IMPROPER ADJUSTMENT OF CLUTCH

SETTING COULD CAUSE ENTRAPMENT,

INJURY OR DEATH. SET CLUTCH

ADJUSTMENT FOR JUST ENOUGH FORCE

TO OPERATE THE DOOR RELIABLY, BUT

NO STRONGER. CONTACT A SERVICE

PROFESSIONAL TO CORRECT ANY

BINDING, STICKING OR OTHER DOOR

PROBLEMS. DO NOT OVERADJUST

CLUTCH SETTING TO COMPENSATE FOR

A POORLY WORKING DOOR.

WARNING

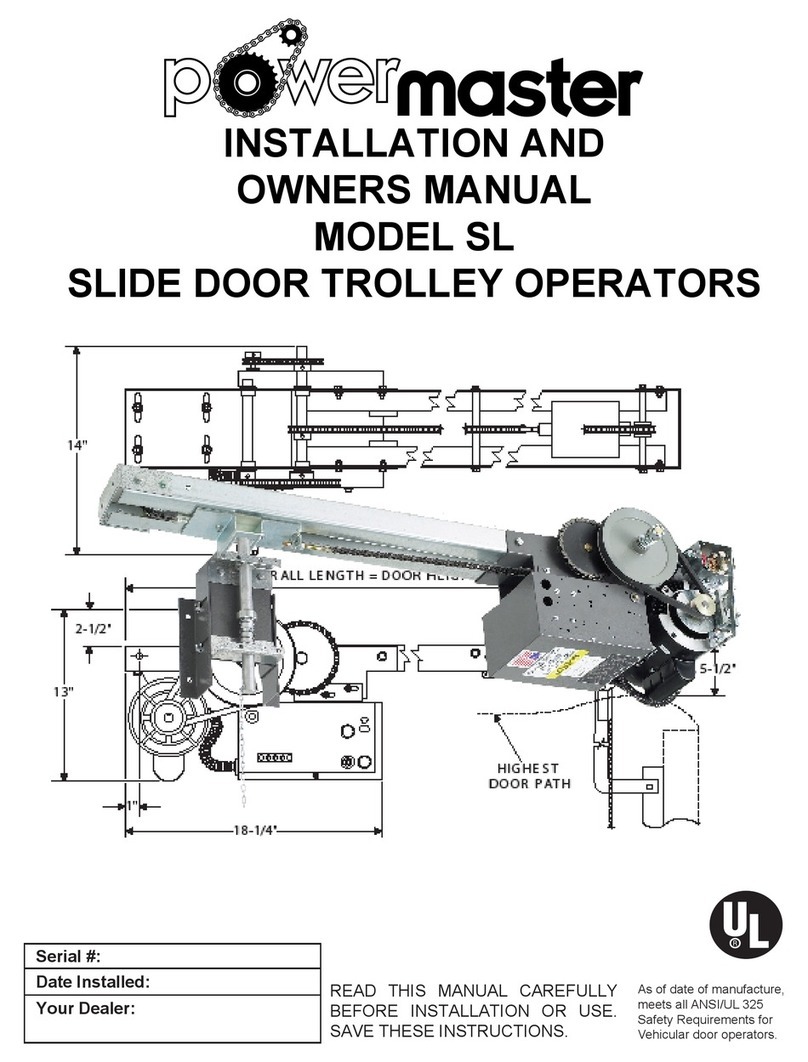

FIGURE 15