3 of 26

www.NabcoEntrances.com GT1400StandardSingle/HurricaneSingleFoldingDoorInstallaonManual

Rev 6-14-21 P/N C-00177

Warning labels are universal and used to alert an individual of potenal harm to one’s self or to others. The following warning labels

are listed in a hierarchy order that denes the most potenal danger rst, and the least potenal danger last. Please refer to this

page in the event that a warning label is displayed within this manual and further denion needs to be explained.

high

Note: Indicates important informaon that provides further instrucon.

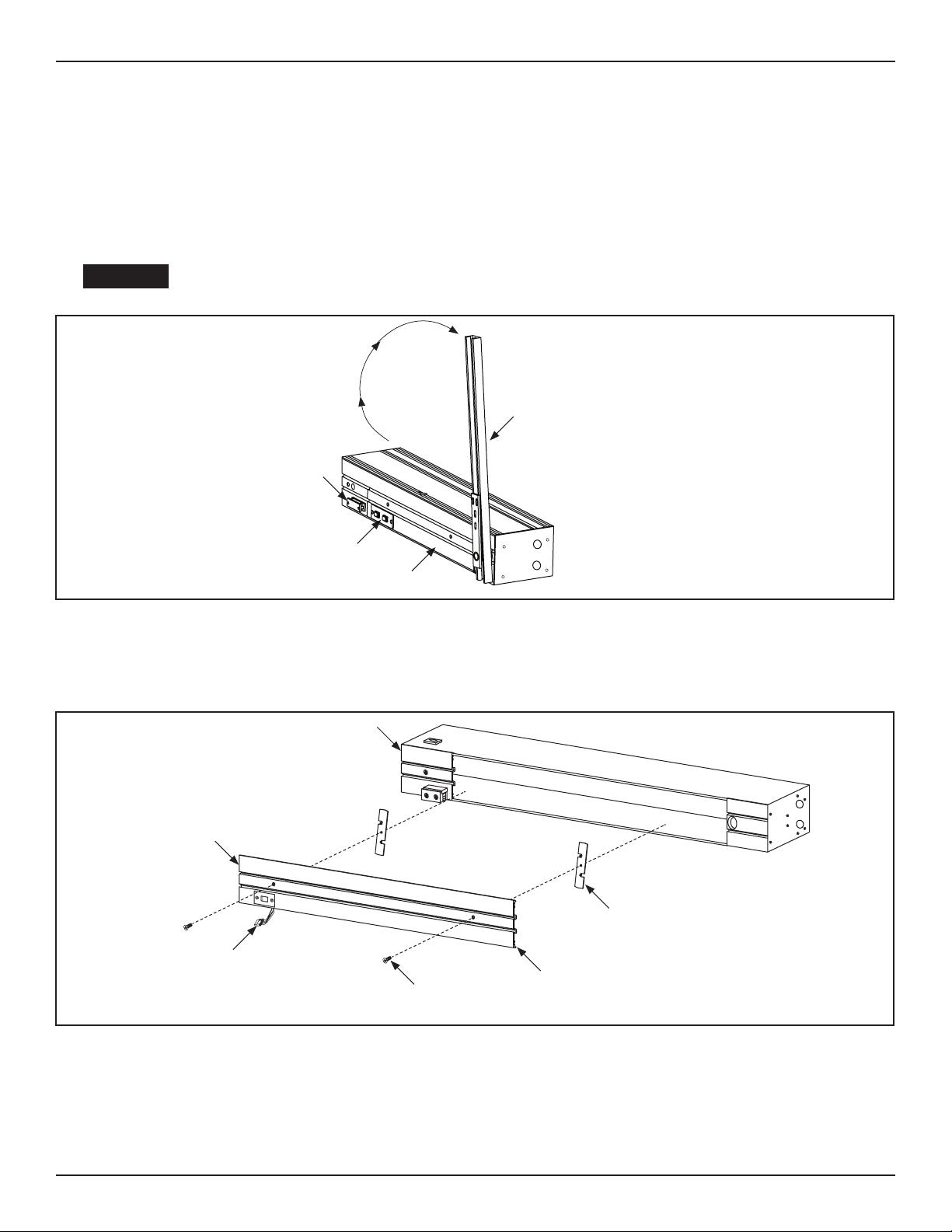

The purpose of this manual is to familiarize the installer and purchaser with the proper installaon and operaon of this system.

It is essenal that this equipment be properly installed and operaonal before the door is used by the public. It is the installer’s

responsibility to inspect the operaon of the entrance system to be sure it complies with any applicable standards. In the United

States ANSI Standard A156.10 covers the GT-1400 Fold Door System. Also in the United States all installed glass must meet ANSI

Standard Z97.1.

All automac equipment complies with UL325 and CAN/CSA -C22.2 No 247-92. Other local standards or codes may apply. Use them

in addion to the ANSI standard. The GT-1400 is listed with the Underwriters Laboratory and is idened as such on the label.