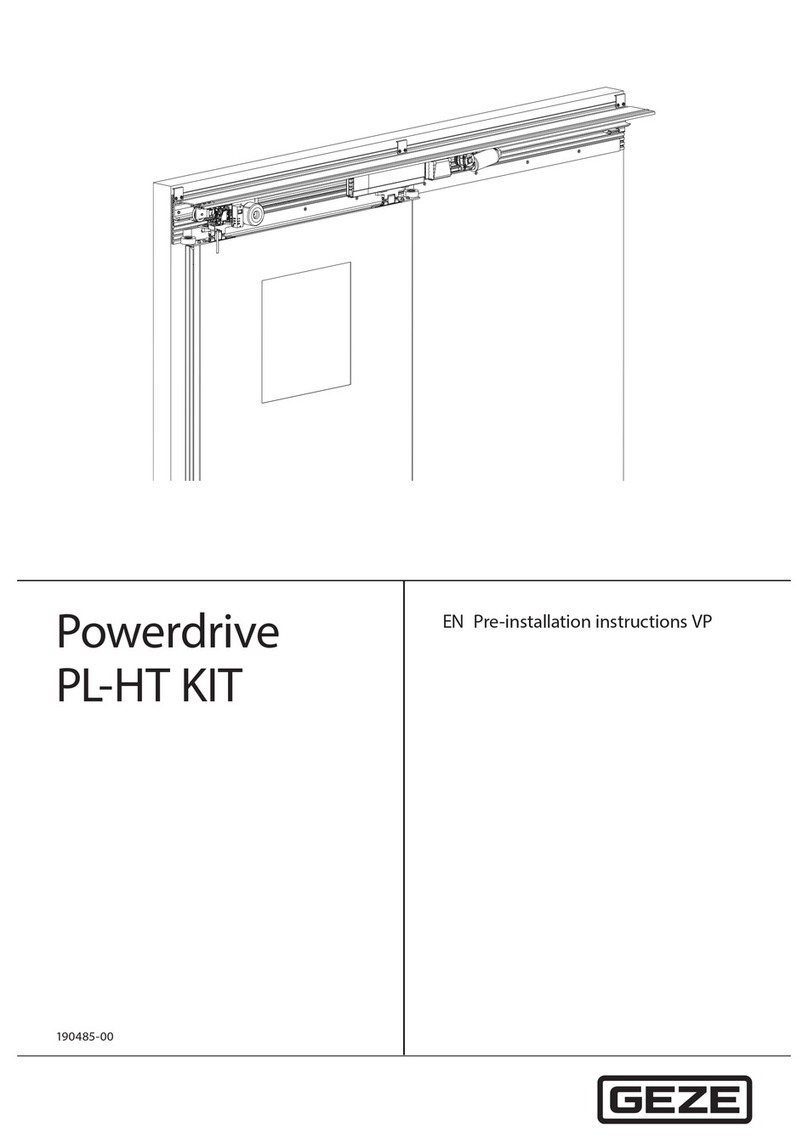

ECdrive H

2

Table of contents

1 Symbols and means of representation............................................................................................................3

2 Product liability ........................................................................................................................................................3

3 Safety instructions...................................................................................................................................................3

3.1 Intended use.......................................................................................................................................................................................................3

3.2 Safety instructions ...........................................................................................................................................................................................3

3.3 Safety conscious working..............................................................................................................................................................................4

3.4 Inspection of the installed system .............................................................................................................................................................4

3.5 Environmentally conscious working .........................................................................................................................................................4

4 Overview.....................................................................................................................................................................5

4.1 Diagrams..............................................................................................................................................................................................................5

4.2 Tools and aids.....................................................................................................................................................................................................5

4.3 Torques.................................................................................................................................................................................................................5

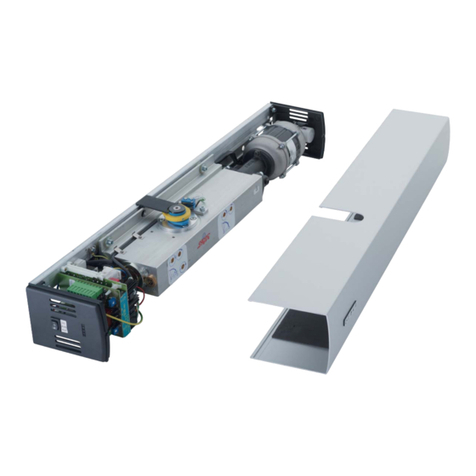

4.4 Components and assembly groups...........................................................................................................................................................5

5 Pre-installation..........................................................................................................................................................6

5.1 Prepare proles .................................................................................................................................................................................................6

5.2 Preparing runner ..............................................................................................................................................................................................6

5.3 Mounting the drive components ...............................................................................................................................................................6

5.4 Connecting transformer and control unit...............................................................................................................................................7

5.5 Connecting drive motor and control unit...............................................................................................................................................7

5.6 Installing cable holders ..................................................................................................................................................................................8

5.7 Final work ............................................................................................................................................................................................................9

6 Installation............................................................................................................................................................... 10

6.1 Preparations on site...................................................................................................................................................................................... 10

6.2 Installation........................................................................................................................................................................................................ 10

6.3 Commissioning................................................................................................................................................................................................15

6.4 Dismantling ..................................................................................................................................................................................................... 16

7 Service and maintenance ...................................................................................................................................17

7.1 Mechanical service.........................................................................................................................................................................................17

7.2 Maintenance check........................................................................................................................................................................................17

8 Troubleshooting.....................................................................................................................................................18

8.1 Mechanical faults............................................................................................................................................................................................18

8.2 Electrical faults.................................................................................................................................................................................................19