Operation Manual for ZBL-R620/R630 Rebar Locator

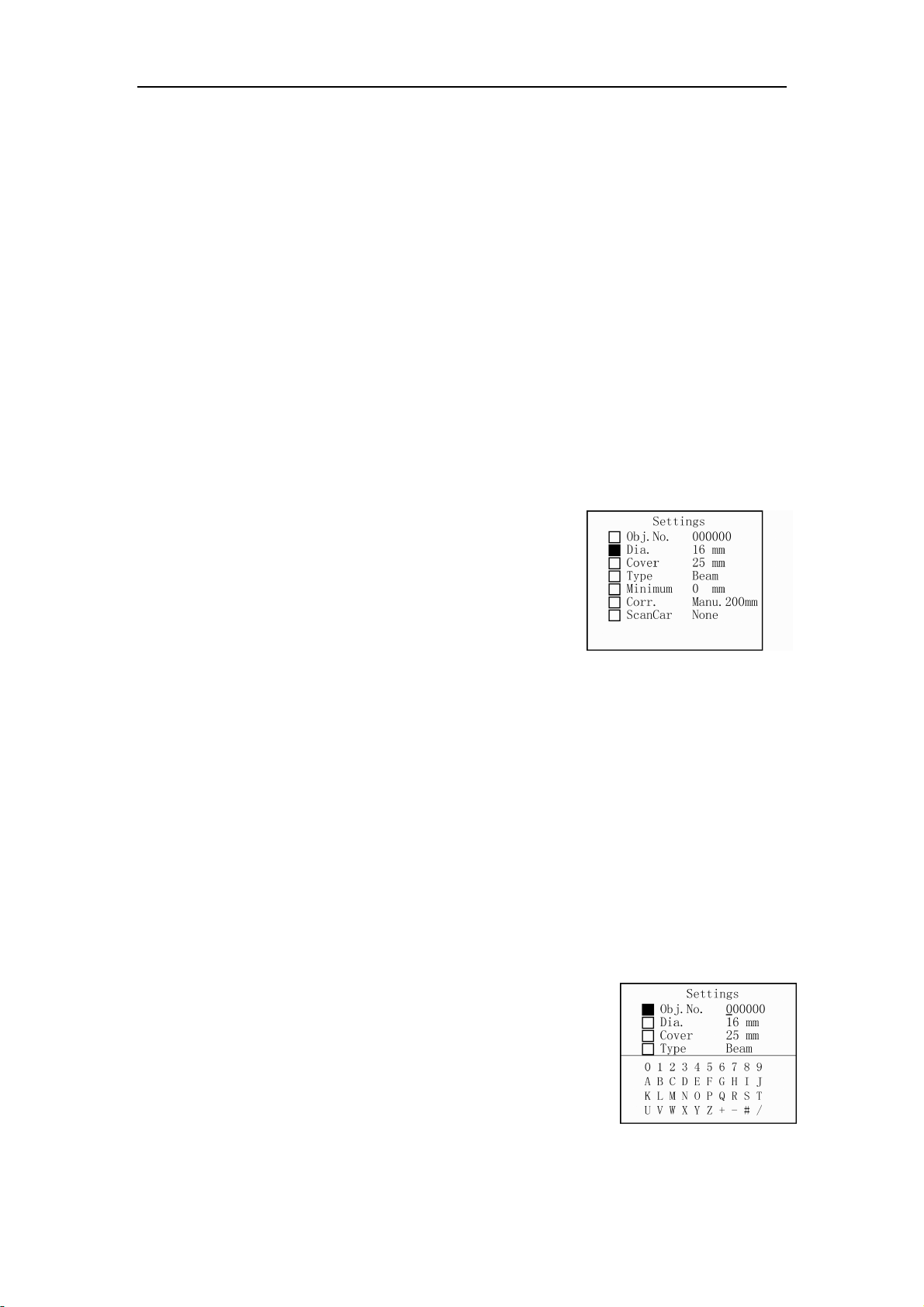

symbols. The initial object code is 000000. When restarting, enter the parameter

setting interface, the initial object code is the previously used code incremented by

one character.

Move the cursor to “object code”, press 【Enter】key, the curser moves to below the

first digit of the code.

Press 【←、→】keys, move the cursor to the digit requiring modification;

Press 【↓】key, a cursor displays in the top-left corner of soft-keyboard;

Press 【↑, ↓、←、→】keys, select a character from the soft-keyboard;

Press 【Enter】key, the selected character now appears in the new object code.

The cursor of object code moves to the next digit and the cursor in soft keyboard will

disappear.

If the next digit needs to be changed, repeat the operation above.

When the object code setting is complete, press the【Save】key to save this object

code. The cursor will disappear, and the interface automatically returns to the

parameter setting interface.

2)Diameter setting – Set the test rebar diameter. The initial value is automatically set to

the previously used rebar diameter value.

When accessing the current setting, the cursor will be shown beneath the diameter value.

Press 【↑, ↓】keys, to increase or decrease the rebar diameter value;

Press 【Save】key, setting are saved, the cursor disappears and the interface

automatically returns to the parameter setting interface.

3) Thickness setting – Set the concrete cover thickness of test rebar, the available range

is 10 ~ 99mm, the initial value is automatically set to the previously used rebar thickness.

When setting thickness:

Press 【↑, ↓】keys, increase or decrease the thickness value,

Press 【Save】key, save setting, the cursor disappears, and the interface

automatically returns to the parameter setting interface.

4) Concrete component type – type of concrete component, including “beam” and

“board”.

Press 【↑, ↓】keys, switch between beam and board. It can automatically judge

if the value of thickness conforms to the international 50204 standard.

5) Minimum thickness – when fast general testing, set the allowed minimum concrete

cover thickness of test rebar. The available range is 0 ~ 100 mm, the initial value is 0 mm.

Press 【↑, ↓】keys, set the minimum concrete cover thickness;

Press 【Save】key, save current setting, the cursor disappears, and the interface

automatically returns to the parameter setting interface.

When the concrete cover thickness is found to be smaller than the minimum thickness,

the apparatus will give a warning. In such an event the thickness value will not be

displayed or saved.

Note: When the minimum thickness is set as 0, the alarm function may be

unavailable.

6) Data correcting – There are two modes, “manual” and “none”, the initial mode is set to

“none”, in which case the apparatus will not make any corrections to the data. To access

this option,