3

Pad Suspension System

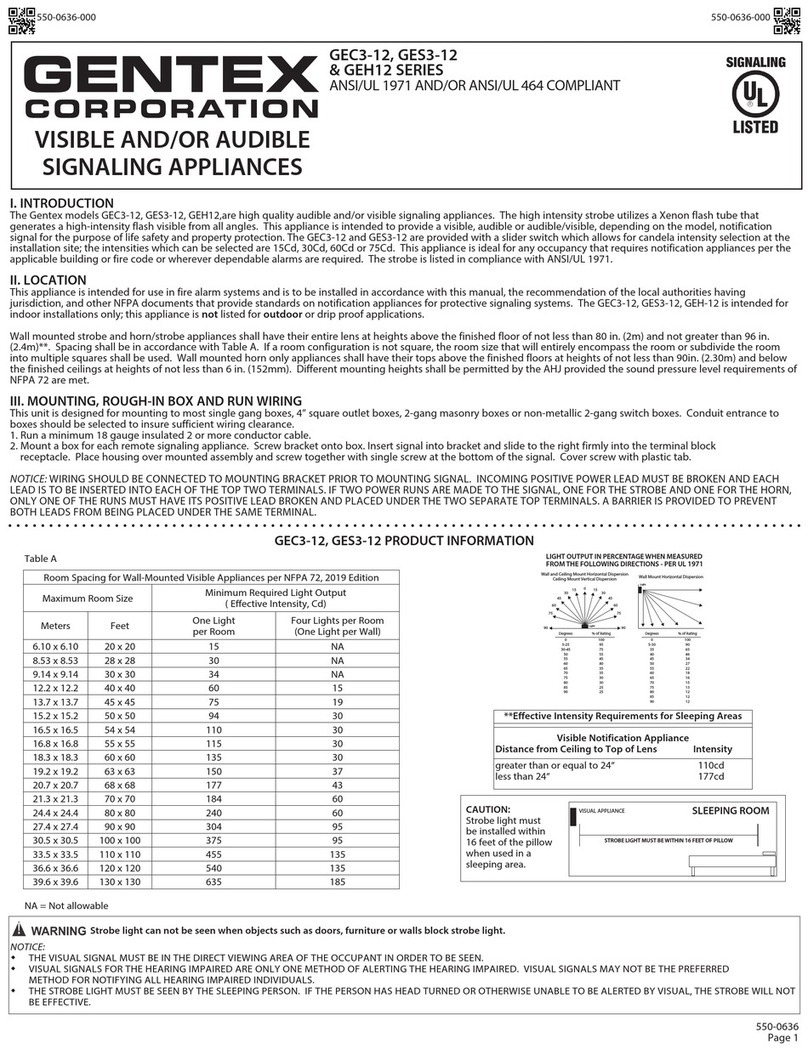

Yourhelmetisequippedwithapadsuspensionsystem(Figure 3),which

consistsofasetofeightwater-resistantpadsattachedtohookdisksonthe

insideofthehelmetshell.Thesetcontainstwotrapezoidalpads(oneincenter

frontandoneincenterback),andsixoblongpads.

Inthestandardpadconguration,thetwooblongpadsinthecrown(top)ofthe

helmetareplacedclosetogether.Inanalternateconguration,thesetwopads

canbespaced1½to1¾inchesaparttoaccommodateaheadset.

The05D11950-5pads(¾inchthick)areinstalled.The05D11950-6pads(1inch

thick)areoptional.Thedifferencesinthicknessallowforpropert.

Figure 3. Pad Suspension System

Hook disk

Oblong

pads

(crown)

STANDARD CONFIGURATION ALTERNATE CONFIGURATION

Trapezoidal pad

Oblong pad Oblong pad

Trapezoidal pad

Oblong pad Oblong pad

Trapezoidal pad

1½ to 1¾ inches

Oblong pad Oblong pad

Trapezoidal pad

Oblong pad Oblong pad

Hook disk

Oblong

pads

(crown)

The helmet is impact-qualied using the standard pad conguration.

This pad conguration provides the required impact protection at all

required impact sites. Alternate pad congurations may not provide

optimal protection at all required impact sites.