GS_GSR_GCR_UserManual_V21.doc / 18.09.2009 GeoSIG Ltd.

GSR / GCR / AS User Manual Page 1

1. Introduction

a

Dear Valued GeoSIG Customer, thank you for purchasing this product.

These Instruments have been optimised to meet the requirements of the majority of customers

out of the box and may have even be delivered tailored to your needs. In any case, to be able

to get the most out of our product, please carefully study this manual, its appendices and

referenced manuals, as well as any other documents delivered with it.

This is a reliable and easy to use device, and at the same time a sophisticated product, which

requires care, attention and know-how in configuring, installing, operating and maintenance.

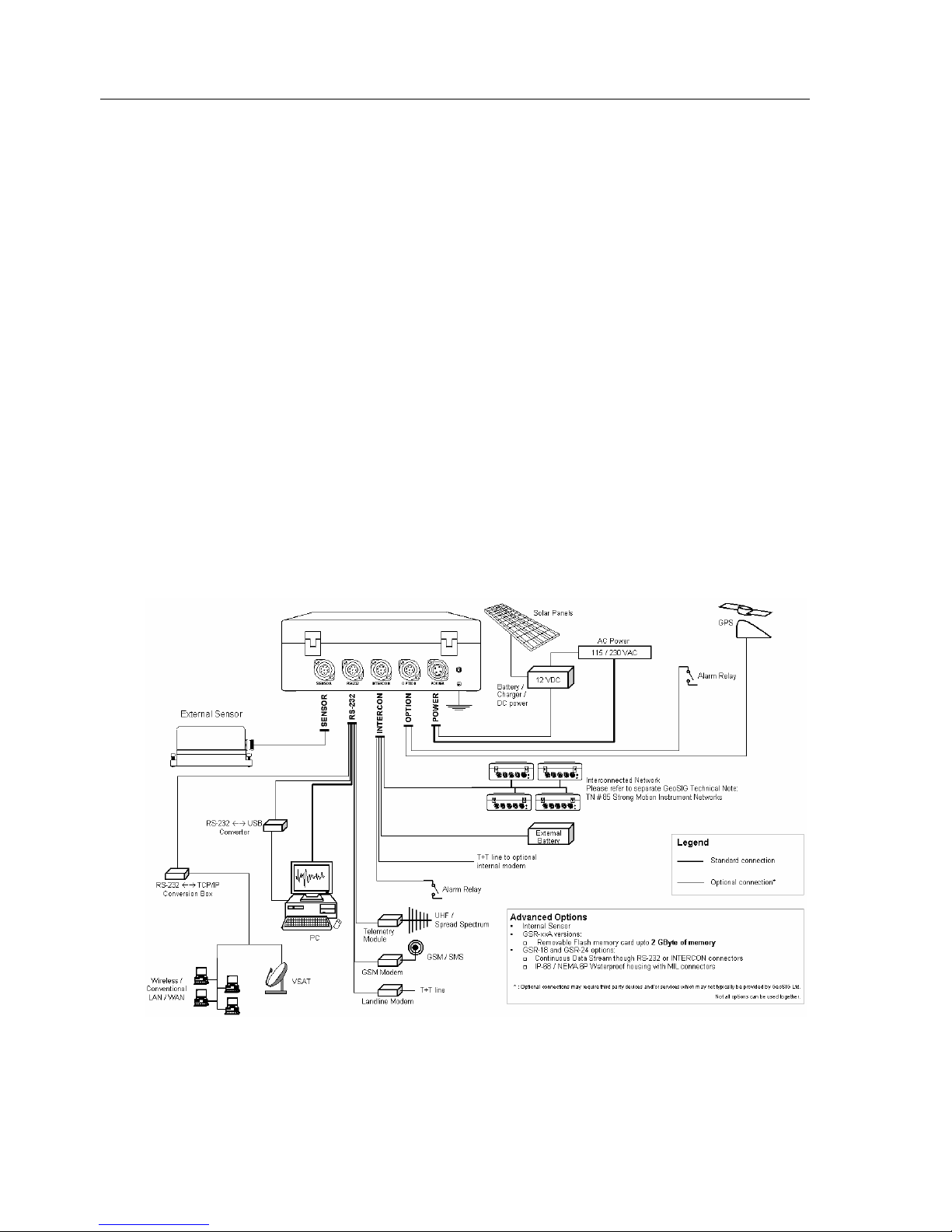

The GCR-12/16 and GSR-12/16/18 are 12, 16 or 18 Bit seismic data acquisition systems. The AS-

12/16 is a 12 or 16 Bit seismic switch with the same specifications as the GSR or GCR instruments

with alarm trigger output but without recording facility. All these devices will be referred to as

“Instrument” in this operation manual unless needed to be specific.

Several types of internally or externally mounted sensors can be used with the Instrument, like

seismometers, geophones, accelerometers or other sensors with single-ended or differential outputs.

The GSR and GCR store the event data in CMOS SRAM, which is power maintained by internal

and/or external batteries or in removable Memory Cards (Flash EEPROM/SRAM, CF Memory Card /

PC Card). Recorded data include the sensor data, clock/timing information and instrument

configuration information.

Frequency response depends on the low-pass filter chosen. For all except GCR the frequency

response is 40% of the sample rate, whereas the sample rates are 100, 200, and 250 SPS.

During normal operation the Instrument continuously amplifies, filters and converts sensor inputs to

12, 16 or 18 Bit digital form and passes these to a pre-event memory. GCR has a permanent

(continuous) recording facility, whereas in GSR and AS, when the specified triggering criteria have

been met, the Instrument either begins recording the data from the pre-event memory and/or issues

an alarm / alarm trigger. In case of recording, by selecting an appropriate length of the pre-event

memory, you can ensure that the entire event, including the first arrival, will be recorded.

Trigger algorithms include STA/LTA ratio triggering and level triggering. The STA/LTA ratio trigger

computes the short term and long term signal averages fifty times per second (every 0.02 seconds).

When the STA exceeds a pre-selected multiple of the LTA, the Instrument begins recording data. The

level trigger continuously compares the incoming signal to a selected threshold and triggers when its

value exceeds the threshold.

The Instrument is typically configured by connecting to a PC (both desktop and laptop models) with an

RS-232 communications port. Besides configuration, this connection facilitates data acquisition and

performing a complete system test from the sensor to the data storage memory, via the menu driven

software GeoDAS.

Configuration, data acquisition or system tests of an Instrument at a remote site may also be

accomplished through the use of modems or other telecommunication methods. Utilisation of a laptop

PC further yields the capability to perform these tasks at the site.

a

GeoSIG continuously improves and enhances capabilities of all products. There may be

several other connectivity, hardware or software options for the Instrument, which are not

covered in this manual. Refer to separate documentation from GeoSIG about available options.

2. Incoming Inspection

All Instruments are carefully inspected both electrically and mechanically before they leave the factory.

Please check if all received items correspond with the packing list and your order confirmation. In case

of discrepancy please contact GeoSIG or your local representative immediately.