2

Contents

Page

Usage for the intended purpose ..............................................................................................................4

Safety note .............................................................................................................................................4

Danger ...................................................................................................................................................4

Attention.................................................................................................................................................4

ATEX (Atmosphère Explosible).................................................................................................................4

Note on the Declaration of Conformity / Declaration by the Manufacturer .........................................4

Important Notes

Explanatory Notes

Scope of supply......................................................................................................................................5

Description .............................................................................................................................................5

Function .................................................................................................................................................6

System components ...............................................................................................................................6

Design....................................................................................................................................................6

NRG 16-41, -41.1; NRG 17-41, -41.1; NRG 19-41, -41.1, step 1...........................................................14

NRG 16-41, -41.1; NRG 17-41, -41.1; NRG 19-41, -41.1, step 2...........................................................14

Attention...............................................................................................................................................14

Note .....................................................................................................................................................14

Tools.....................................................................................................................................................14

Examples of installation NRG 16-41.1, NRG 17-41.1, NRG 19-41.1.......................................................15

Key.......................................................................................................................................................16

Installation

NRG 16-41, -41.1; NRG 17-41, -41.1; NRG 19-41, -41.1 ........................................................................7

Name plate / marking .............................................................................................................................8

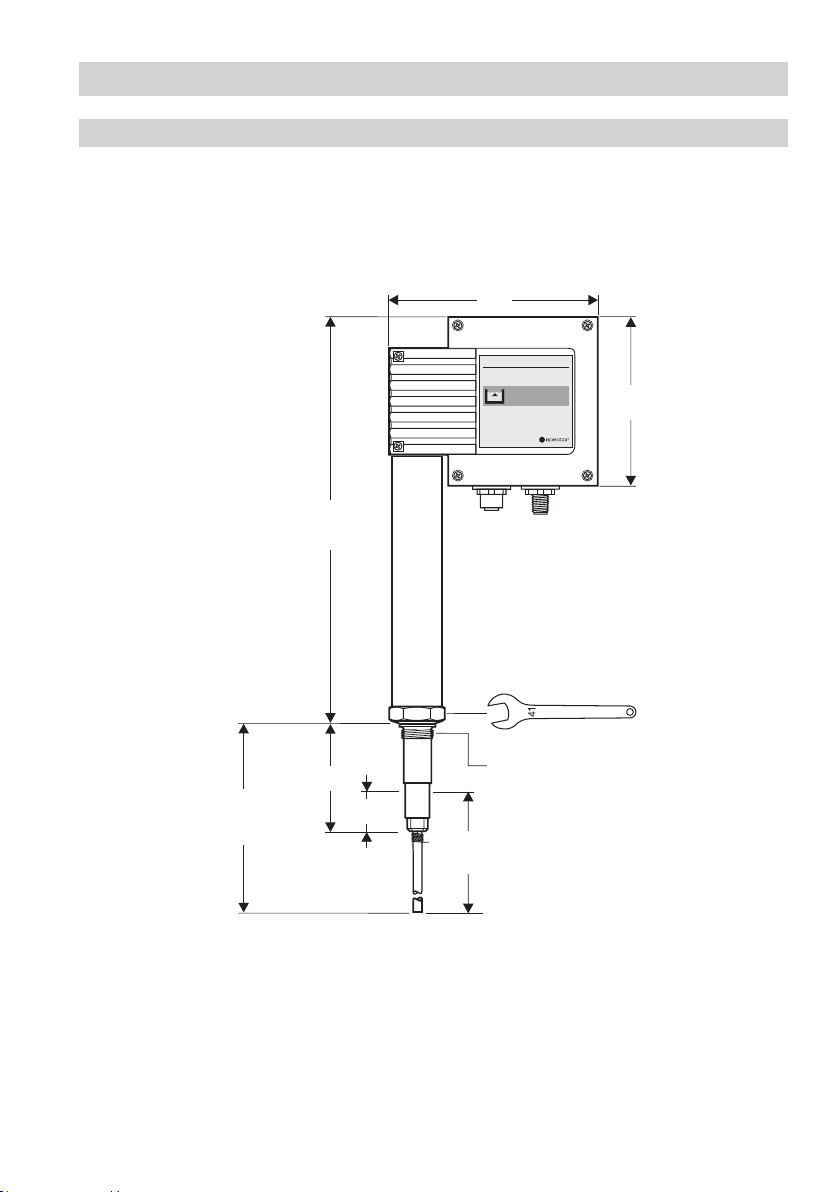

Dimensions NRG 16-41, -41.1; NRG 17-41, -41.1...................................................................................9

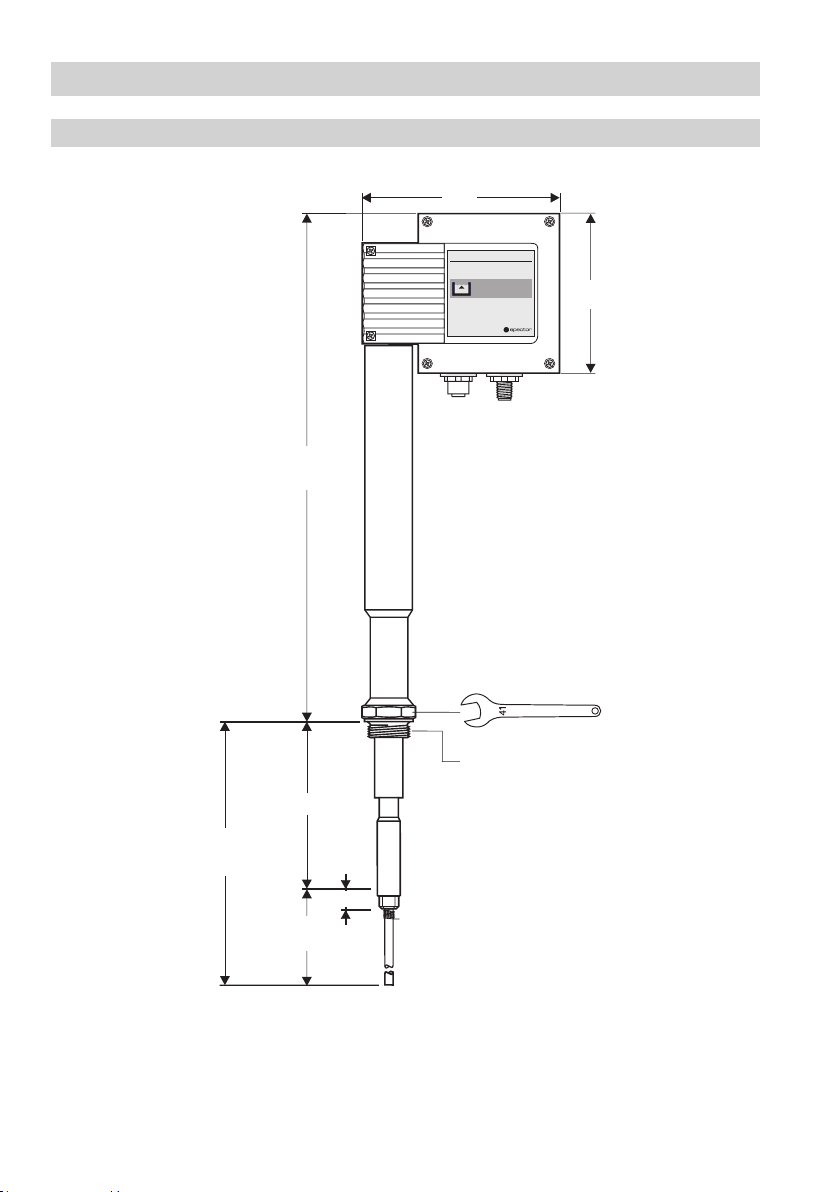

Dimensions NRG 19-41, -41.1..............................................................................................................10

Technical Data

NRG 16-41, -41.1; NRG 17-41, -41.1; NRG 19-41, -41.1 ......................................................................11

Key.......................................................................................................................................................13

Design

NRG 16-41, -41.1; NRG 17-41, -41.1; NRG 19-41, -41.1 ......................................................................12

Key.......................................................................................................................................................13

Functional Elements