Safety

Use for the intended purpose

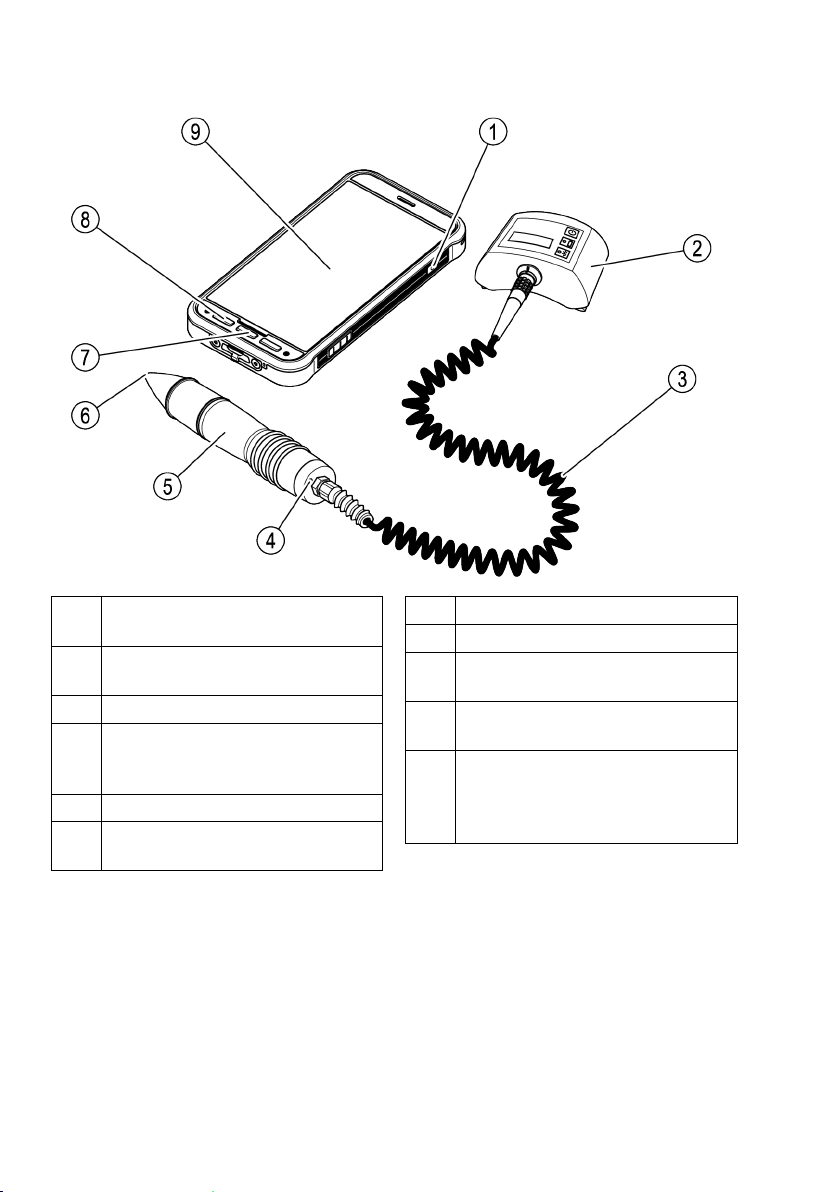

The VKP 42 steam trap testing equipment is used

for testing steam traps for loss of steam and

banking up of condensate. Do not use or operate

the VKP 42 steam trap testing equipment in

potentially explosive atmospheres.

The VKP 42 Ex steam trap testing equipment is

used in areas at risk of gas explosion for testing

steam traps for loss of steam and banking up of

condensate.

Correct use includes compliance with the

instructions given in this installation & operating

manual, in particular obedience to all safety

instructions.

Use for the intended purpose also includes

compliance with the data collector installation &

operating manual, particularly the safety notes.

Any other use of the equipment is considered to be

improper.

The following use, in particular, shall be considered

as improper use:

Using equipment without Ex protection in a

potentially explosive atmosphere

Use of the equipment by untrained personnel

Basic safety notes

Explosion hazard

Use the equipment in areas at risk of gas

explosion only under the following conditions:

In areas at risk of gas explosion, only use

equipment type VKP 42 Ex with VKPS 40 Ex

measuring transducer, VKPC 40plus Ex Com

box and VKPN 42 Ex Smart-Ex 02 *** DZ1

data collector.

Make sure that all components of the

equipment are undamaged.

Never connect or disconnect components of

the equipment in potentially explosive

atmospheres.

Never open components of the equipment in

potentially explosive atmospheres.

Do not charge batteries of individual

components of the equipment in potentially

explosive atmospheres.

Risk of explosion if the pipeline to be tested is

carrying voltage.

Before starting the test make sure that no part

of the pipeline is carrying voltage. You can

achieve this e.g. by earthing the pipeline.

There is a risk of explosion if the wrong USB

charging cable is used. Charging with the wrong

USB charging cable can damage equipment

components or batteries. If this happens,

explosion protection is no longer effective.

Only charge the VKPC 40plus Ex Com box

outside the potentially explosive atmosphere

using the supplied VKPA 40plus USB charging

cable.

Risk of explosion due to spark-over.

Do not use any items in the explosion-risk area

that could generate sparks. Do not use the

supplied file!

Pay attention to the safety notes for the

VKPN 42 Ex data collector type Smart-Ex 02 ***

DZ1. You will find these in the equipment

certificate provided.

Risk of severe injuries

Risk of deadly electric shocks if a test is

performed on live steam traps!

Make sure that the traps to be tested are not

live.

The trap to be tested is hot and under pressure.

Before carrying out any tests make sure that the

following requirements are met:

Make sure there is no skin contact with the

trap to the tested or other parts of the

installation.

Always wear protective gear when

performing the tests.

Make sure that there are no fluid leaks at the

area of the trap to be tested.

Risk of deadly electric shocks if defective

components are used!