3

Foreword

This Installation & Operating Manual will help you

to use the following testing equipment correctly,

safely and cost-efficiently:

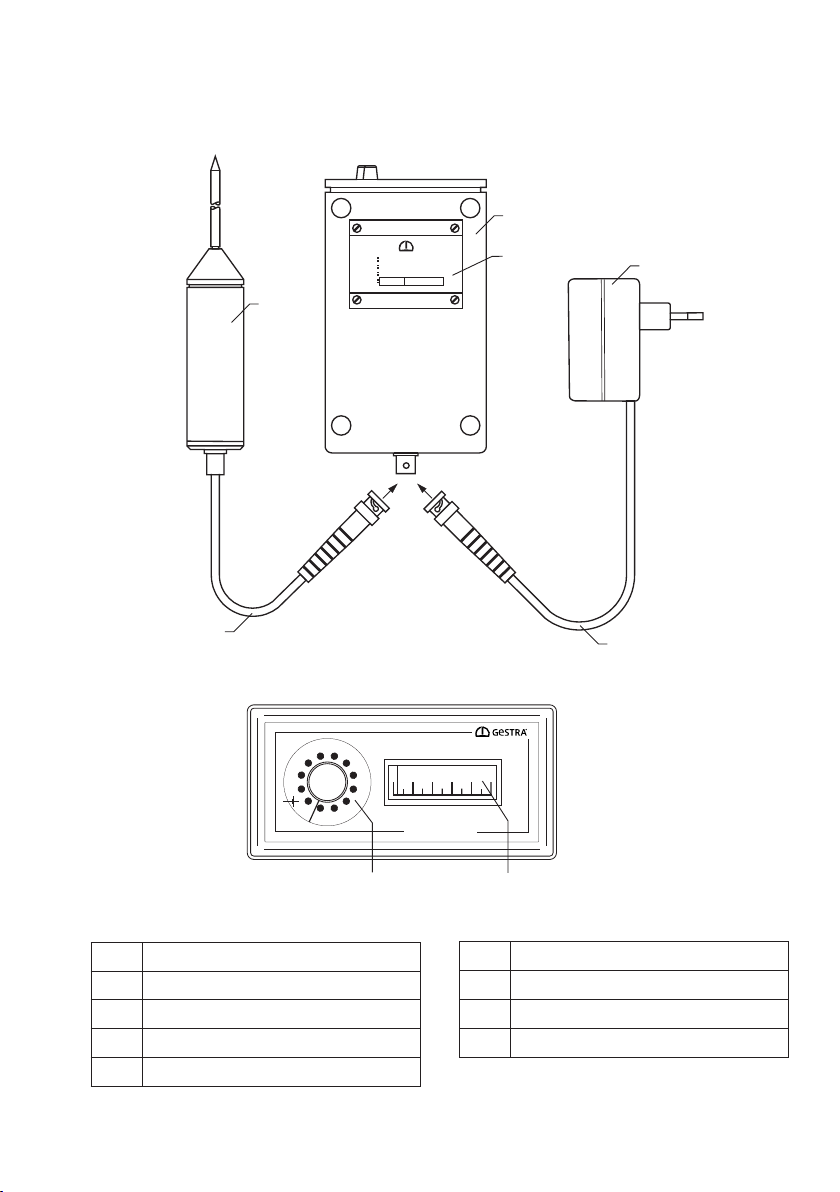

VKP 10

This steam trap testing equipment is referred to

below simply as equipment.

This Installation & Operating Manual is intended

for all persons bringing this equipment into ser-

vice, and operating, using, servicing, cleaning or

disposing of the equipment. In particular, the In-

stallation & Operating Manual is aimed at service

technicians, trained specialist personnel, and

qualified and authorised operating personnel.

Each of the above must have read and under-

stood the content of this Installation & Operating

Manual.

Following the instructions in the Installation &

Operating Manual helps to avoid danger and

increases the reliability and service life of the

equipment. In addition to the instructions in this

Installation & Operating Manual, compliance with

the applicable binding rules on accident preven-

tion in the country and location of use, and with

the generally recognised technical regulations for

safe and proper working, is essential.

Please also read and follow the instructions in

the manufacturers' operating manuals for the

data collector, particularly the safety notes.

Availability

Always keep this Installation & Operating Manual

in the leather bag for the equipment. Make sure

that the Installation & Operating Manual is avail-

able to the operator.

The Installation & Operating Manual is part of the

equipment package. Hand over this Installation

& Operating Manual if you sell or pass on the

equipment to a third party.

Formatting features in the

document

Different types of information in the Installation

& Operating Manual are formatted in different

ways.

This helps you to distinguish easily between the

following types of information:

Normal text

Cross references

◗Lists

◗Bullet points in lists

➢Action to be taken.

These tips contain additional informa-

tion, e.g. about cost-efficient use of the

equipment.

Security

Usage for the intended purpose

The steam trap testing equipment VKP 10 is used

for testing steam traps. Do not use or operate the

steam trap testing equipment VKP 10 in poten-

tially explosive atmospheres.

Usage for the intended purpose also includes

reading and adhering to all instructions in this

manual, particularly the safety notes.

Use for the intended purpose also includes

compliance with all the instructions given in the

manufacturers' operating manuals for the data

collector.

This applies in particular to the safety notes.

Any other use of the equipment shall be consid-

ered as improper use.

The following usages in particular shall be con-

sidered as improper use:

◗The use of equipment in potentially explosive

atmospheres without explosion protection

◗The use of the equipment by untrained

personnel

3

Vorwort

Diese Betriebsanleitung hilft Ihnen beim

bestimmungsgemäßen, sicheren und

wirtschaftlichen Gebrauch des folgenden

Prüfgeräts:

VKP 10

Dieses Prüfgerät für Kondensatableiter wird im

Folgenden kurz Gerät genannt.

Diese Betriebsanleitung wendet sich an jede

Person, die dieses Gerät in Betrieb nimmt, betreibt,

bedient, wartet, reinigt oder entsorgt. Die

Betriebsanleitung richtet sich insbesondere an

Kundendienst-Monteure, ausgebildetes

Fachpersonal und das qualifizierte und autorisierte

Betriebspersonal.

Jede dieser Personen muss den Inhalt dieser

Betriebsanleitung zur Kenntnis genommen und

verstanden haben.

Das Befolgen der Anweisungen in der

Betriebsanleitung hilft Gefahren zu vermeiden und

die Zuverlässigkeit und die Lebensdauer des Geräts

zu erhöhen. Beachten Sie außer den Hinweisen in

dieser Betriebsanleitung unbedingt die im

Verwenderland und an der Einsatzstelle geltenden

verbindlichen Regelungen zur Unfallverhütung sowie

die anerkannten technischen Regelungen für

sicherheits- und fachgerechtes Arbeiten.

Beachten und befolgen Sie auch die Hinweise in der

Betriebsanleitung des Herstellers zum

Datensammler, insbesondere die

Sicherheitshinweise.

Verfügbarkeit

Bewahren Sie diese Betriebsanleitung immer in

der Ledertasche für das Gerät auf. Stellen Sie

sicher, dass die Betriebsanleitung für den

Bediener verfügbar ist.

Die Betriebsanleitung ist Bestandteil des Geräts.

Liefern Sie diese Betriebsanleitung mit, wenn Sie

das Gerät verkaufen oder in anderer Weise

weitergeben.

Gestaltungsmerkmale im Text

Verschiedene Elemente der Betriebsanleitung sind

mit festgelegten Gestaltungsmerkmalen versehen.

So können Sie die folgenden Elemente leicht

unterscheiden:

normaler Text

Querverweise

Aufzählungen

Unterpunkte in Aufzählungen

Handlungsschritte.

Diese Tipps enthalten zusätzliche

Informationen, wie besondere Angaben

zum wirtschaftlichen Gebrauch des Geräts.

Sicherheit

Bestimmungsgemäßer Gebrauch

Das Prüfgerät für Kondensatableiter VKP 10

dient zum Prüfen von Kondensatableitern.Das

Prüfgerät für Kondensatableiter VKP 10 darf

nicht im explosionsgefährdeten Bereich betätigt

oder betrieben werden.

Zum bestimmungsgemäßen Gebrauch gehört auch

das Beachten und Befolgen aller Angaben in dieser

Anleitung, insbesondere der Sicherheitshinweise.

Das Beachten und Befolgen aller Angaben in der

Betriebsanleitung zum Datensammler gehört

ebenfalls zum bestimmungsgemäßen Gebrauch.

Dies gilt insbesondere für die darin enthaltenen

Sicherheitshinweise.

Jeder andere Gebrauch des Geräts gilt als

bestimmungswidrig.

Insbesondere folgender Gebrauch gilt als

bestimmungswidrig:

der Einsatz eines nicht explosionsgeschützten

Geräts im explosionsgefährdeten Bereich

der Einsatz des Geräts durch nicht

eingewiesenes Personal