5

Always wear protective gear when

performing the tests.

Make sure that there are no fluid leaks at the

area of the trap to be tested.

Risk of deadly electric shocks if defective

components are used!

Never open the components of the

equipment.

Never use any defective or damaged

components.

Before recharging the equipment make sure

that the used cables are in good working

condition.

Information on property damage

or malfunctions

Condensation may have formed in the

equipment in the event of sudden or drastic

temperature changes.

After temperature changes leave the

equipment switched off until the temperature

of the equipment reaches ambient

temperature.

Allow any condensation on the equipment to

dry out completely.

Static charges may cause damage to electronic

components and/or lead to malfunctions.

Wear electrically insulated shoes when

performing tests.

Improper handling may cause damage to

electronic components and/or lead to

malfunctions.

Never open the components of the equipment.

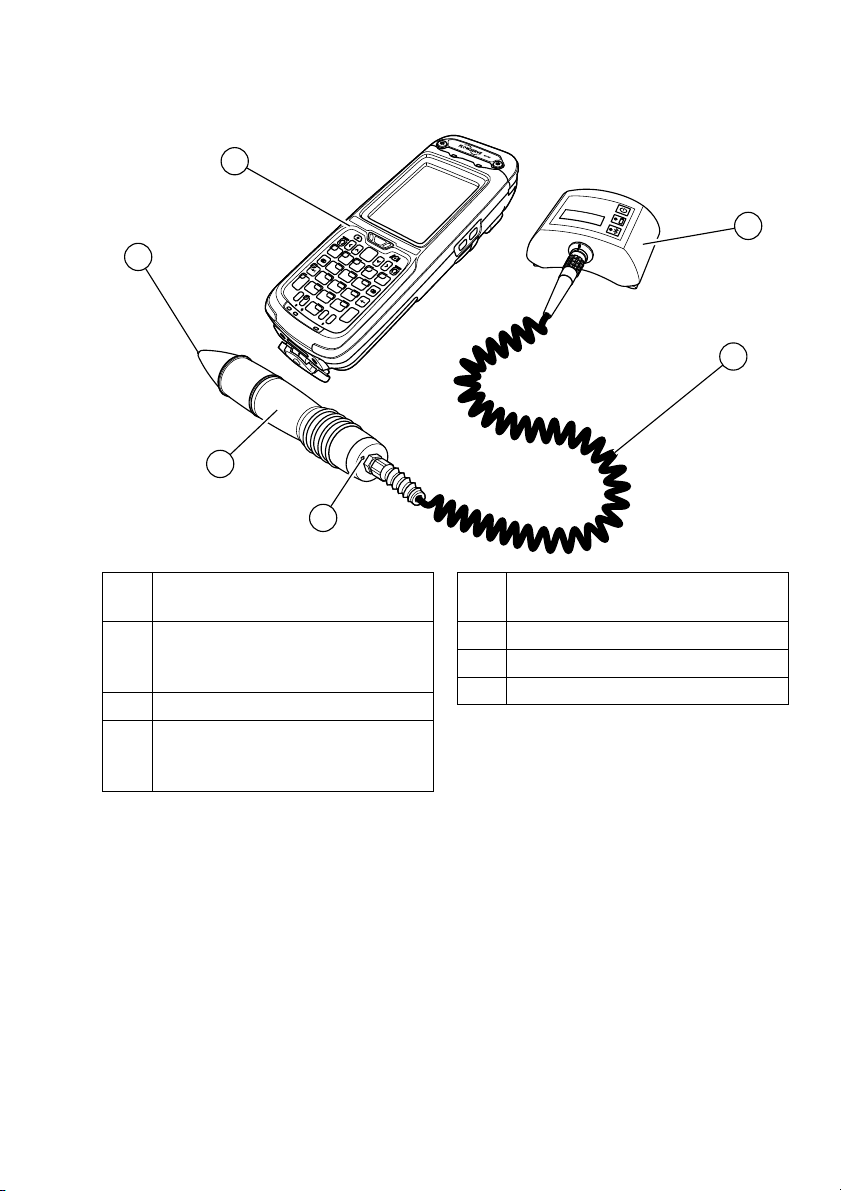

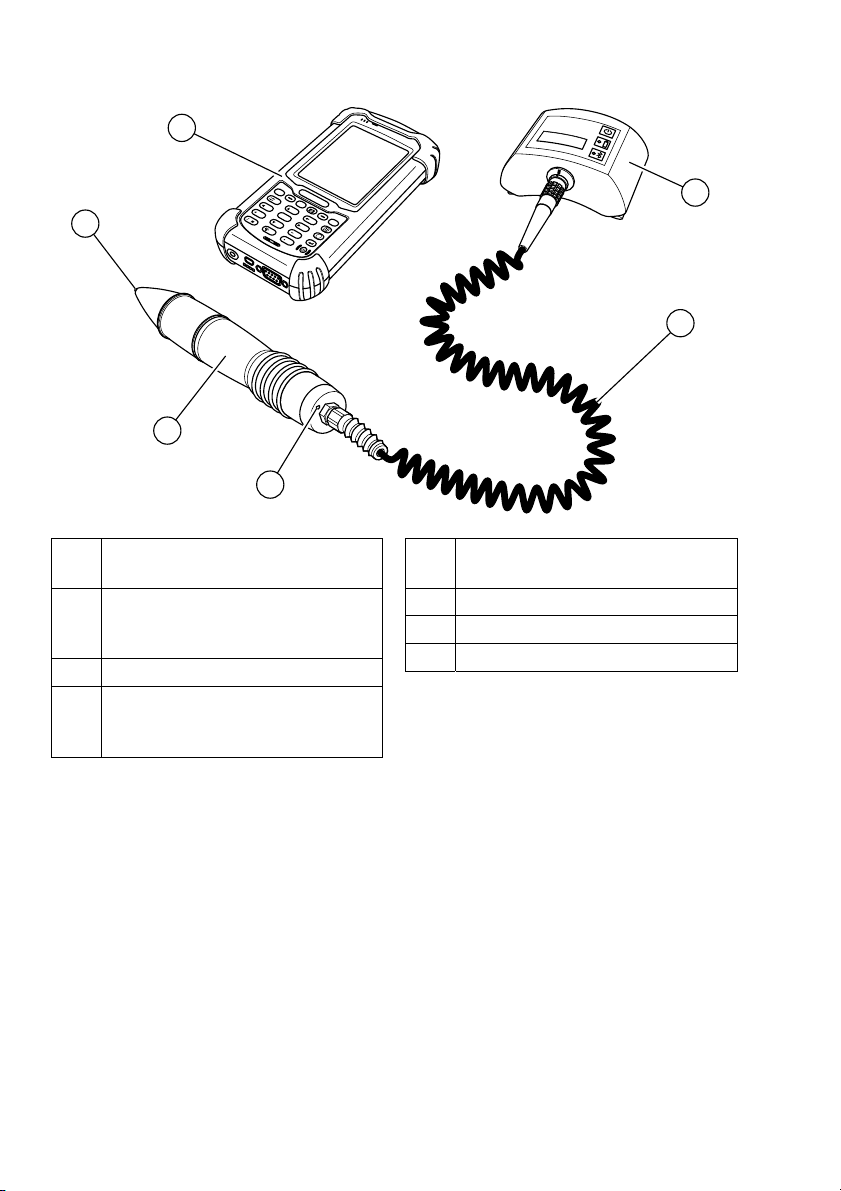

If the measuring probe does not touch the trap

firmly at the right position and angle the

readings may be incorrect.

Make sure the sensor tip of the measuring

probe touches only a bare metallic surface.

If the tests are performed on different points on

a steam trap the readings may be faulty.

Make sure the sensor tip touches always the

same test point. Make sure the sensor tip is

perpendicular to the surface of the steam trap

when it touches the test point.

Qualification of personnel

A qualified person must be acquainted with and

experienced in the following:

The pertinent on-site rules and regulations for

preventing fire and explosions as well as

industrial safety regulations

Working on pressure equipment

Working with dangerous (hot or pressurized)

fluids

Observing all notes and instructions in this

installation & operating manual and the

applicable documents

Working with personal computers (PCs)

Working with menu-driven software

Analysing and interpreting steam trap test

results

Protective gear

The required protective gear depends on the types

of fluid used and the regulations on site. For more

information on suitable safety clothing and safety

gear refer to the safety data sheet of the fluid in

question.

Protective gear comprises the following items:

protective helmet

work boots

industrial leather gloves

Depending on local rules and regulations and the

noise level generated by the plant some form of ear

protection to EN 352 must be worn.

Depending on local rules and regulations and the

fluid used in the plant some form of eye protection

to EN 166 must be worn.