Type K Thermocouple Pipe Clamp Temperature Probe

Using the 80PK-10 to Measure Pipe Temperature

2

Using the 80PK-10 to Measure

Pipe Temperature

1. Using the miniature thermocouple connector,

connect the 80PK-10 to a compatible Type K

temperature measuring device.

2. Turn on the measuring instrument and select the

appropriate range and scale.

If you are using a temperature conversion module

(the 80TK, for example), insert the module into

the VΩand COM inputs of the meter and select

the mV dc function.

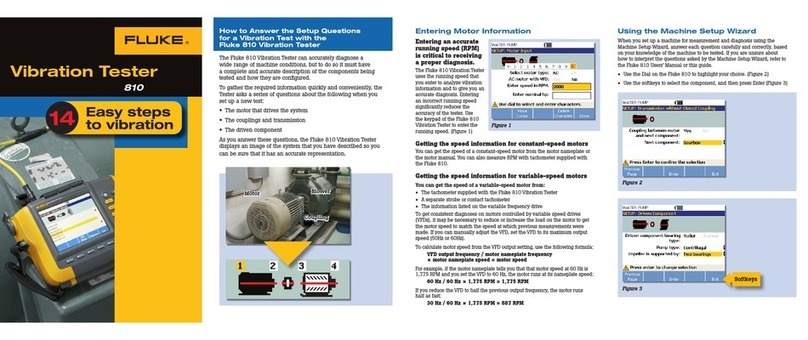

3. Slide the protective cover towards the inside of

the jaw to reveal the thermocouple.

4. Using your thumb or the palm of your hand, press

down on the plunger to open the jaws of the probe

wide enough to easily encompass the pipe.

Center the pipe on the “V” notch (see Figure 1)

on the jaw of the probe and relax pressure on the

plunger.

5. Read the temperature on the measuring

instrument. When no heat or cold is applied to the

sensor the measuring instrument should display

the ambient temperature. If the instrument does

not readout properly, refer to “Troubleshooting”.

6. When measurement is complete, remove the

80PK-10 from the pipe and slide the protective

cover back over the thermocouple. This cover

protects the thermocouple when not in use.

Measurement Considerations

The 80PK-10 is designed to be compatible with any

temperature-measuring instrument that accepts

miniature Type K thermocouples with cold reference

junction compensation. The accuracy of the

temperature-measurement is a factor of the combined

accuracy of the temperature measuring instrument and

the 80PK-10.

A lowering of the temperature at the sensor contact

point is less likely (and response time is faster) on

clean, polished, thermally conductive surfaces, then

on surfaces with low thermal conductivity, such as

plastic or rough, greasy surfaces. To obtain the best

thermal contact and performance, the pipe must be

centered in the “V” notch of the probe jaw.

To get the most accurate temperature measurement,

adjust the connection between the sensor and the pipe

until you get the maximum or minimum temperature

reading.

WCaution

To prevent damage to the probe,

do not rotate the clamp when

measuring the temperature of a

rough surface.

Troubleshooting

When no heat or cold is applied to the probe, the

measuring instrument should display the ambient

temperature. If the measuring instrument does not do

so, try the following:

1. Verify that the temperature measuring instrument

is designed to be used with Type K

thermocouples. The instrument should have a

yellow input connector and/or be marked with a

“K”.

2. Check for an open circuit indicator on the

measuring instrument. Some thermometers have a

built in circuit to indicate if the connected probe

is open. (All Fluke instruments have this feature.)

Refer to instruments owners’ manual to see if this

feature is available.

If you suspect a broken connection, use an

ohmmeter to check probe continuity from pin to

pin. If the ohmmeter reads ≤10 Ω, the probe is

good.

3. Short the two input connectors to the instrument

with a piece of wire. If the instrument is

functioning properly it should display the ambient

temperature.

Cleaning

WCaution

To prevent damage to the probe,

do not use solvents that may

deteriorate the handle and plunger

of the probe.

Using warm-soapy water, brush the sensor lightly

with a toothbrush. Excessive or abrasive brushing can

damage the sensor and void the warranty. If necessary

dip the brush (but not the sensor) in rubbing alcohol.