3

1GENERAL SAFETY INSTRUCTIONS

1.1 Basic Operation ..................................................................................................................5

1.2 Basic Safety Precautions ....................................................................................................5

1.3 Safety Instructions Governing Specific Operational Phases ..............................................6

1.4 Warning of Electrical Dangers ............................................................................................7

1.5 Grounding Instructions Shall Include the Following ..........................................................8

1.6 Before Operating ................................................................................................................9

1.7 During Operation ...............................................................................................................9

1.8 After operating ...................................................................................................................9

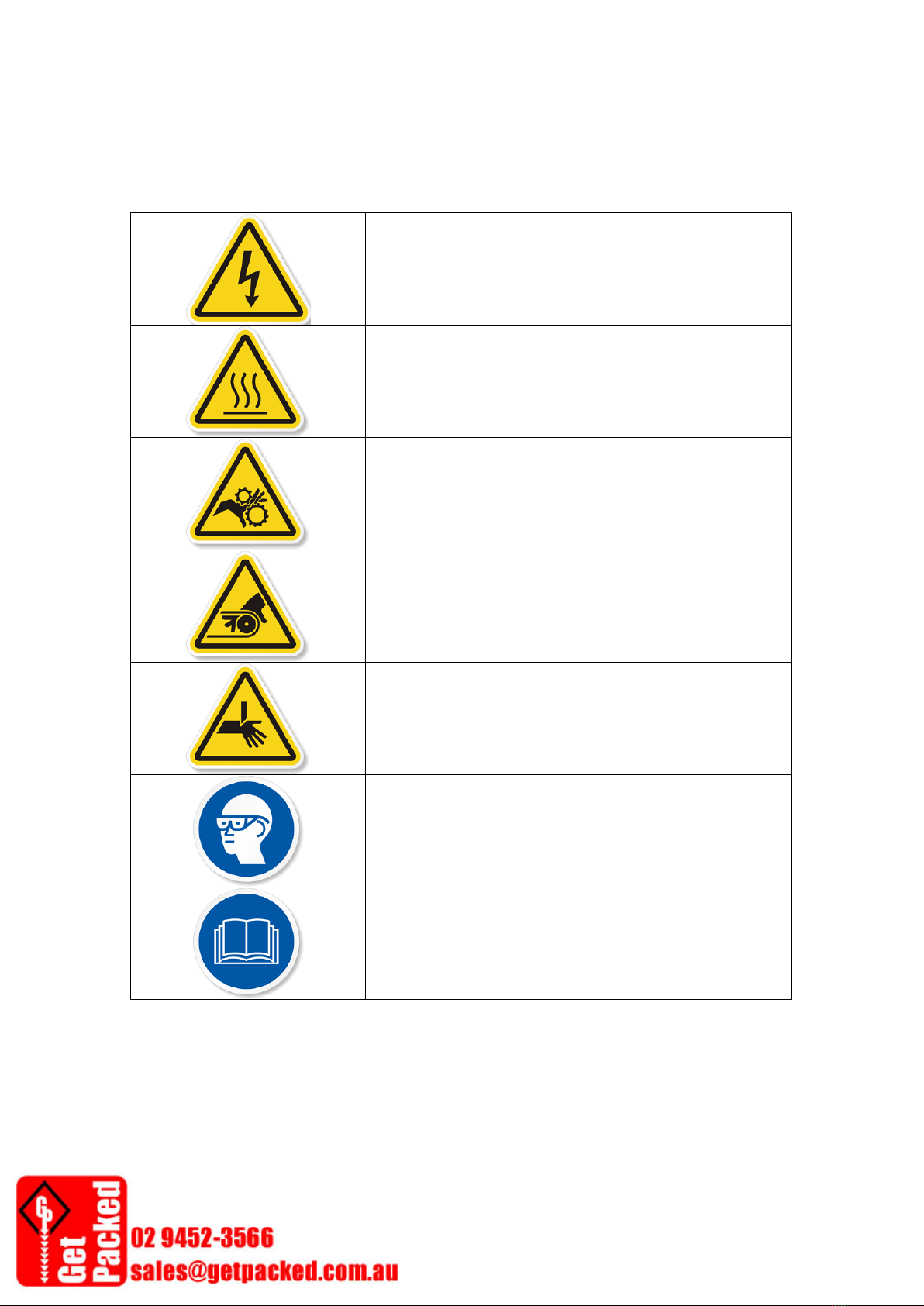

1.9 Signs .................................................................................................................................10

2MACHINE INFORMATION

2.1 Areas of Application .........................................................................................................11

2.2 Environmental Information .............................................................................................11

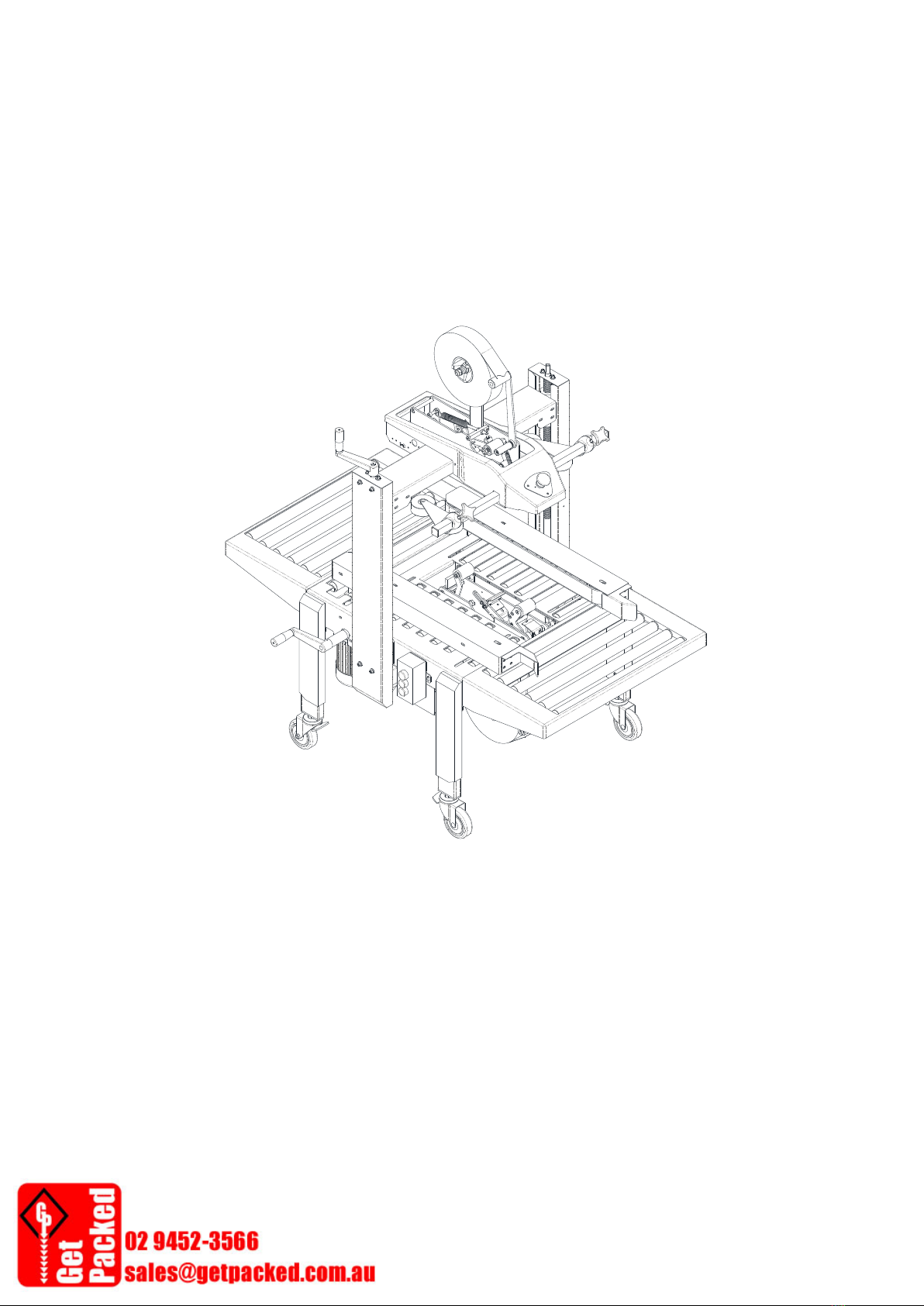

2.3 Machine Description ........................................................................................................12

2.4 Safety Devices ..................................................................................................................12

2.5 Technical Specification .....................................................................................................14

2.6 Identification Data of the Machine ..................................................................................16

3BEFORE OPERATING THE MACHINE

3.1 Shipping ............................................................................................................................17

3.2 Transportation & Unload Machine from Pallet ...............................................................17

3.3 Operation Space ...............................................................................................................18

3.4 Construction and Units ....................................................................................................19

3.5 Control Panel ....................................................................................................................19

3.6 Tape Threading ................................................................................................................21