TABLE OF CONTENT

1. GENERAL INFORMATION.................................................................................. 1

1.1 NOTE OF INSTALLATION........................................................................................1

1.2 NOTICE OF OPERATION ........................................................................................2

2. SPECIFICATION ................................................................................................. 3

2.1 SPEC. TABLE...........................................................................................................3

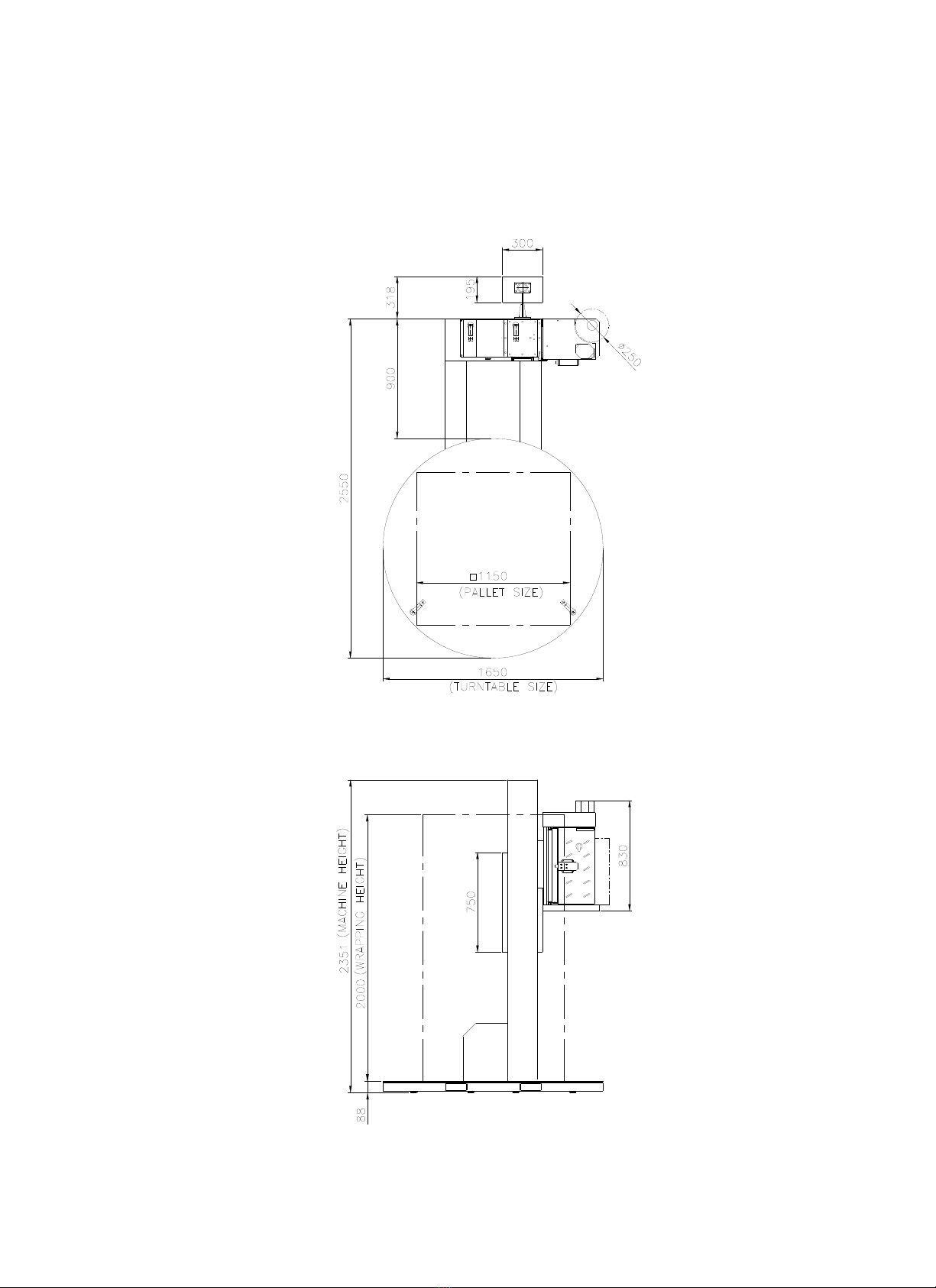

2.2 MACHINE DIMENSION............................................................................................4

2.3 MACHINE DESCRIPTION........................................................................................5

3. OPERATION DESCRIPTION .............................................................................. 6

3.1 INSTALLMENT .........................................................................................................6

3.2 REMINDER OF INSTALLATION ..............................................................................7

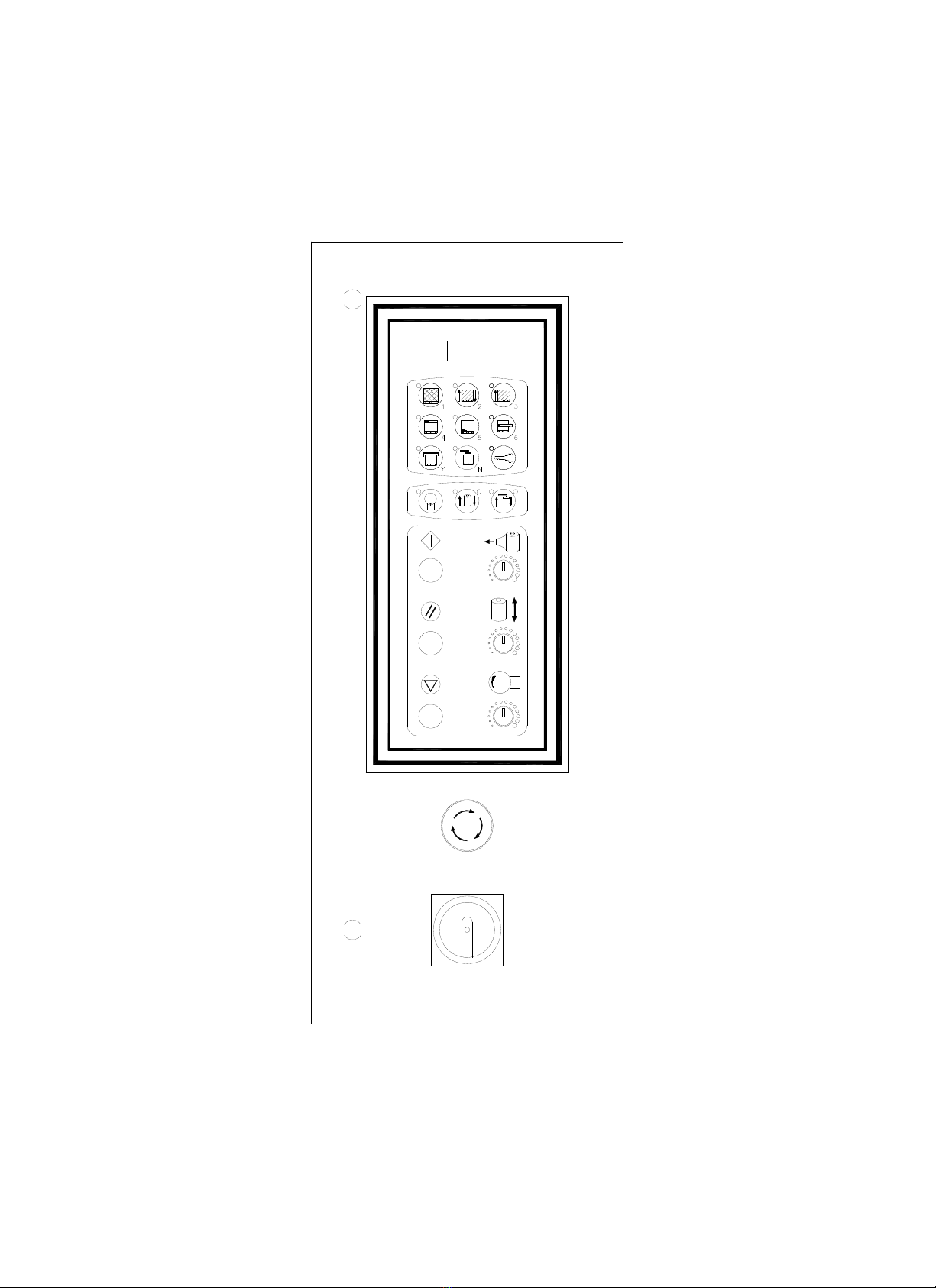

3.3 OPERATION OF CONTROL PANEL........................................................................8

3.4 OPERATION DESCRIPTION ...................................................................................9

3.5 ELEVATOR UNIT....................................................................................................14

3.6 CALIBRATION SETUP DESCRIPITION ..................................................................16

4. ELECTRICAL .................................................................................................... 22

4.1 ELECTRICAL CAPACITY.......................................................................................22

4.2 ELECTRICAL DIAGRAM........................................................................................23

5. TROUBLE SHOOTING ..................................................................................... 35

5.1 GENERAL ADJUSTMENT......................................................................................35

5.2 RUNNING AND SELF TEST ..................................................................................36

5.3 SUGGESTION FOR SOLVING “ER0” ....................................................................37

5.4 TROUBLE SHOOTING WITH EXP-108W MACHINE ............................................38

6. PART LIST......................................................................................................... 47

6.1 SEAT.......................................................................................................................47

6.2 TOWER ..................................................................................................................50

6.3 ELEVATO ...............................................................................................................53

6.4 CONTROL BOX......................................................................................................58