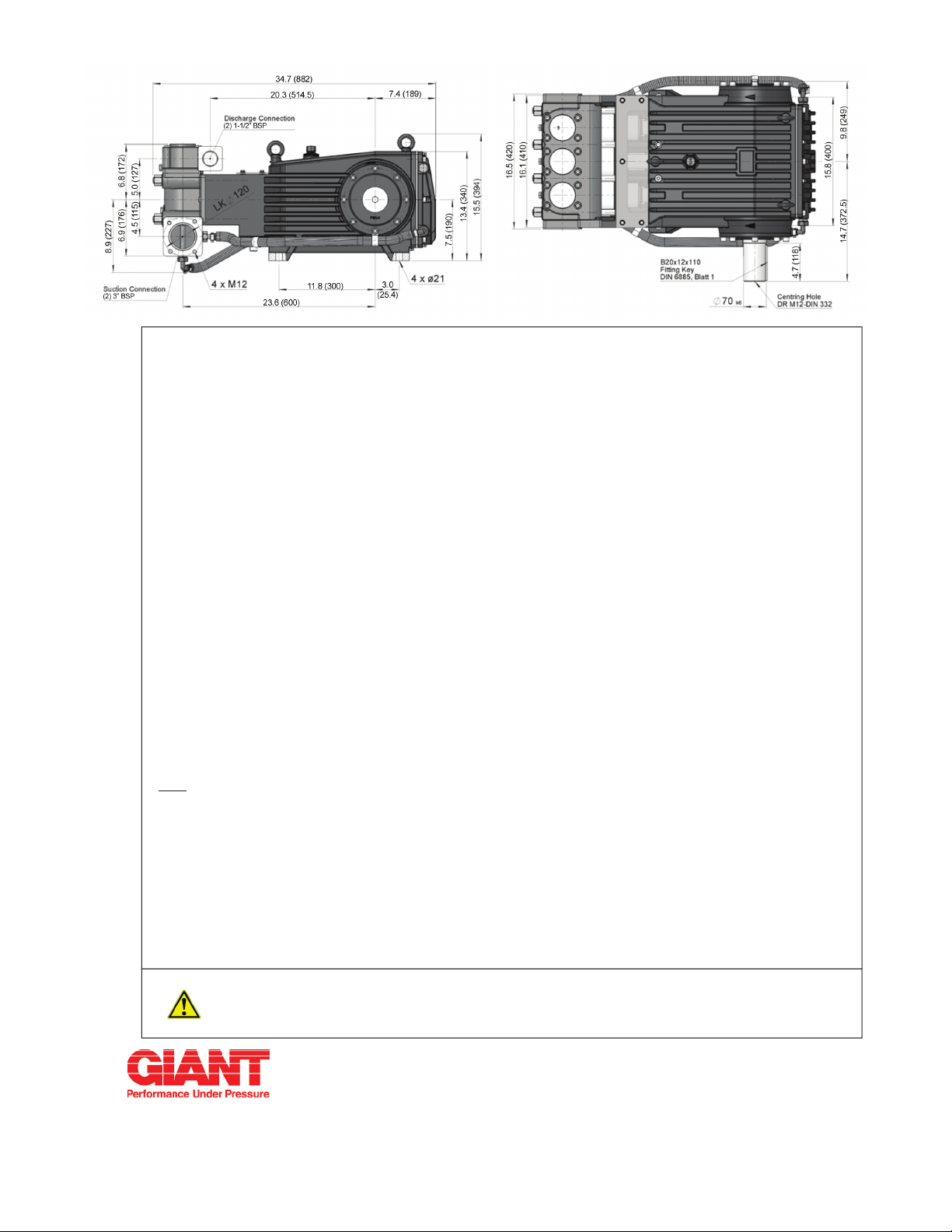

7

7. Maintenance and Servicing

Basedonthethreadtypeandtherequiredtightening

torques,observethetableonpage6.

7.1 Special tools required

Thefollowingspecialtoolsarerequiredforassembly:

-Assemblingtool(codeno.15.0038)

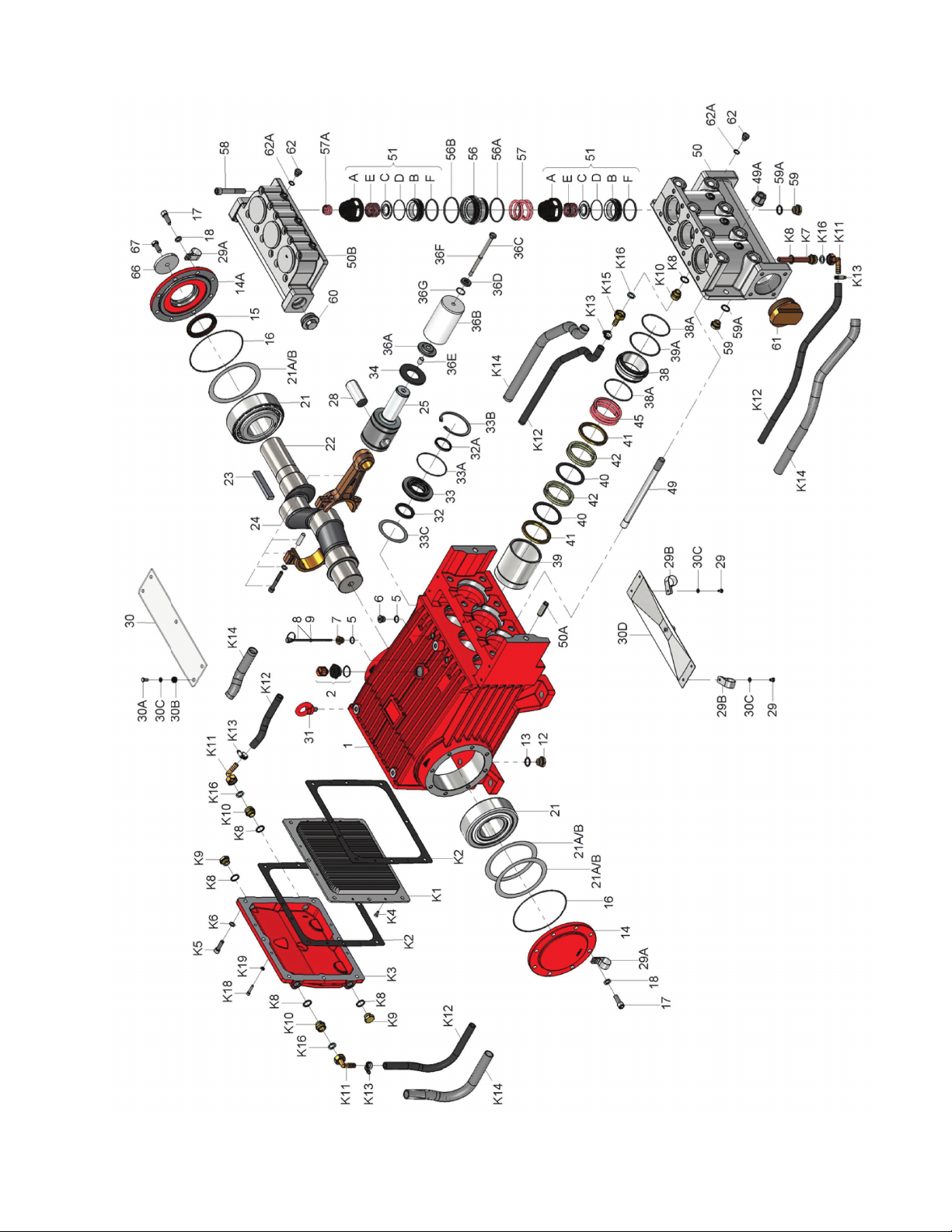

7.2 Suction and Discharge Valves

Loosenscrews(58),liftdischargevalvecasing(50B)

upandaway.

Takeoutpressuresprings(57).

Pulloutthecompletevalves(51)togetherwiththe

pressurevalveholder(56)usinganassemblytool

(orderno.07662).

To dismantle valves:

Thespringtensioncap(51A)isscrewedtogether

withthevalveseat(51B).

Screwoffspringtensioncap,takeoutsprings(51E)

andvalveplate(51C).

ChecksealingsurfacesandO-rings(51D,51F).

Replacewornparts.

Beforere-fittingthevalves,cleanthesealing

surfacesinthecasingandcheckforanydamage.

Tightenscrews(58)totherequiredtorque.

Checktorquetensionafter8-10operatinghours.

8.3 Seals and Plunger

Screwoffhexagonnuts(49A)andhosecoupling

(K11andK15),removepumpheadtogetherwithseal

case(38)fromcrankcase(1).

Ifnecessary,carefullytapthevalvecasing(50)past

thecentringstud(50A)usingarubberhammer.

Ifnecessary,supportthepumpheadby

restingitonwoodenblocksorbyusinga

pulley.

Removetensionscrew(36C)andtakesealsleeve

(39)togetherwithallmountedpartsoutofthedrive.

Pullplungerpipeoutofsealassemblyandcheckfor

anydamage.

Pulloutspiralrings(42),guiderings(41)andsupport

rings(40)andcheckforanydamage.

Becarefulnottodamagesealsleeve(39)

andguidering(41).

Checktheinnerdiameteroftheguidering

forwearandifnecessaryreplacetogether

withspiralring(42)andsupportring(40).

Cleanallparts.

Newpartsshouldbelightlycoatedwith

silicongreasebeforeinstallation.

Insertthesealunit(40,41,42,43)intothesleeve.

Pushtheceramicplungercarefullythroughtheseals

fromthecrankcaseside.Ifnecessary,thesealscan

beheldtightlyusingasuitablepipesupportheldon

theothersideofthesealsleeve.

Takeoutthesealcase(38)fromthevalvecasing

(50)andcheckO-rings(38A)(ifnecessarysecure2

screwdriversinthefrontO-ringgroovetoextractseal

casingfromvalvecasing).

Coatsealswithsilicongreasebeforeinstalling.

Mountingsurfacesofthecrankcaseand

valvecasingmustbecleanandfreeof

damage.

Thecomponentsmustlieexactlyand

evenlyononeanother.

Thesameexactnessappliesforall

centringpositionsinthecrankcase,

intermediatecasing,pressure-andvalve

casing.

Theymuststandverticallyoneachother.

Coatthesealsleevelightlywithanti-corrosivegrease

(e.g.molycoteno.Cu-7439)initsfittedareatowards

thecrankcase.

Insertsealsleevesintotheircrankcasefittings.

Coatthethreadsofthetensionscrew(36C)lightly

withthreadglueandinsertittogetherwithanew

copperring(36D)throughtheceramicpipe.

Turnthepumpbyhanduntiltheplunger(25)rests

againsttheplungerpipe.

Tightentensionscrewtotherequiredtorque.

Threadgluemustnevercomebetween

theplungerpipe(36B)andcentring

sleeve(36E).

Overtensioningoftheplungerpipeby

excessivetighteningofthetensionscrew

and/ordirtordamageonthemounting

surfacescanleadtoplungerpipe

breakage.

Insertthesealtensionspring(45)andO-rings(38A,

39A)intothesealsleeve(39).

Mounting Valve Casing:

Putsealcases(38)inthecentringholesofthevalve

casing,thenpushvalvecasingcarefullyontocentring

studs(50A).

Tightenhexagonnutsevenlyandcrosswisetothe

requiredtorque.

Thetorquetensiononthescrews(49A)

mustbecheckedafter8-10operating

hours;thepumpmustbeatzero

pressure.

Thereafterthetensionistobechecked

every200operatinghours.

If required, supplementary assembly instructions

can be requested from the manufacturer Giant

Industries.

GP8076 PUMP REPAIR INSTRUCTIONS