Gilson Company, Inc. 1-Touch Vibratory Sieve Shaker: SS-10

Page 4

1.0 UNCRATING & ASSEMBLY INSTRUCTIONS

2.0 PREFACE

1. The SS-10 weighs approximately 90lb (40kg). Use

appropriate equipment and manpower to uncrate the

sieve shaker. Wear safety glasses and work gloves.

2. Examine the shipping carton for signs of damage before

opening. Report damage to the shipper immediately.

Leave the carton as intact as possible to facilitate return

shipping, if necessary.

3. Lift the Base Assembly (Item (1). See the Exploded

Diagram on pg. 10) from the carton, and position it on

a solid, level work surface. Examine the unit again for

damage that may have been concealed.

4. The plastic Clearance Spacer (2) is secured for ship-

ping to the top of the SS-10 Base Assembly with three

1/4-20 x 1.75 stainless steel flat-head screws (4). Us-

ing the included Allen key wrench, remove the three

screws and set aside. Leave the spacer on top of the

base assembly.

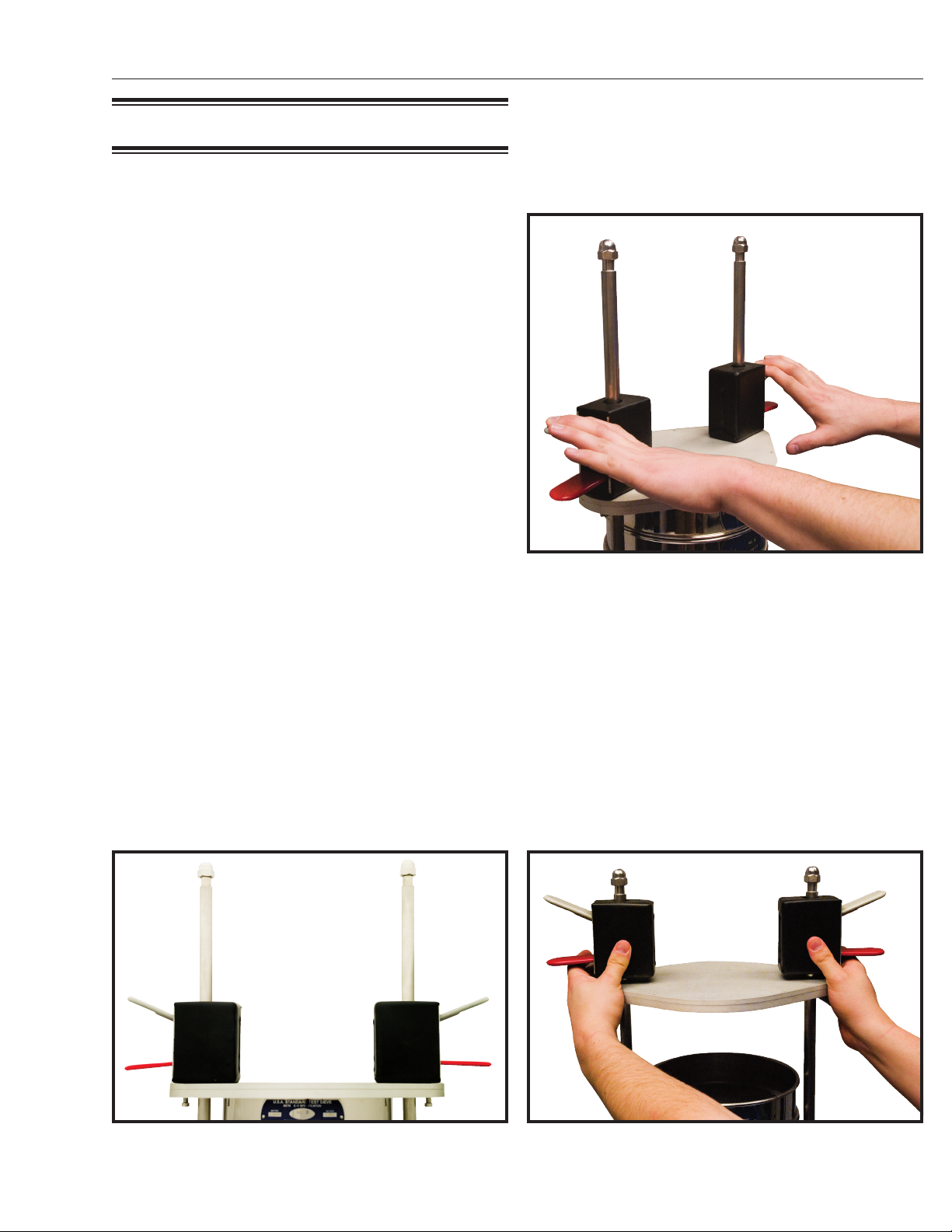

5. The Sieve Stack Assembly includes the two Clamp Rods

(5), bottom and top Covers (3 and 6), Clamps (9), and

top and base Gaskets (12 and 13), shipped partially

assembled. To complete assembly, rotate the Clamps

so that the tabs are facing outward. Slide the Top Cover

Plate up and secure it to the clamps by installing the

10-32 x 1 Shoulder Bolts (10) through the bottom of

the plate into the threaded holes in the bottom of each

clamp. Tighten Securely.

6. Place the Sieve Stack Assembly on top of the plastic

Clearance Spacer, aligning the three holes in the spacer

and base plate with the threaded holes in the top of the

base assembly. Install the three stainless steel flat-head

screws, and tighten securely.

7. Install the Base Gasket (13) into the recess in the Bot-

tom Cover (3).

8. Move the assembled SS-10 into place on a solid, sub-

stantial, and level work surface capable of supporting

the machine during operation.

9. Insert the female end of the included power cord into

the power connection on the back of the SS-10. Power

ON/OFF is controlled by the rocker switch adjacent to

this connection.

Gilson’s new 1-Touch Vibratory Sieve Shaker for 8in and

200mm sieves combines the latest in electronic control with

proven particle sizing technology for fast, accurate separa-

tions. Three-dimensional sieving action evenly distributes

and continuously reorients particles across the mesh sur-

face to insure optimum sieving performance. The SS-10 is

suitable for a variety of materials with particle sizes from

No.10 (2mm) to No.635 (20µm). Fast-acting sieve clamps

adjust quickly with little effort. Power level, sieving time

and interval pauses are all controlled and programmed on

the touch screen. Up to 99 testing profiles can be stored in

memory to insure exact repeatability.