Gilson Tapping Sieve Shaker Manual 4

NOTE: The main device controlled by the timer may be

restricted to operating on a more limited electrical supply

range. Check the device carefully to ensure compatibility

with your electrical supply.

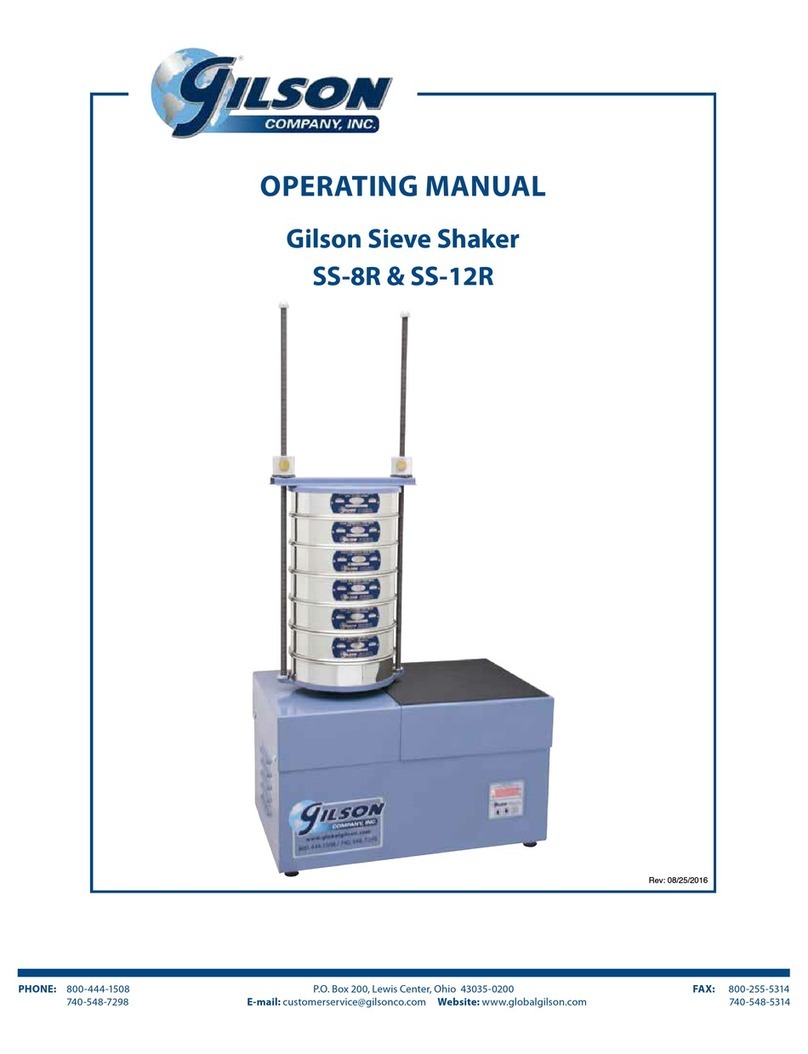

NOTE: The SS-8R and SS-12R Sieve Shakers are equipped

with a tapping mechanism which makes a loud noise. If

the noise is unacceptable, consider using the SSA-805R

Sound Enclosure.

NOTE: Bolting the machine down is not a substitute for

leveling. Bolting the shaker down will cause forces from

the unbalanced sieve stack to damage the drive mecha-

nism. This damage is not covered by warranty.

4.0 MAINTENANCE

ALWAYS

4.1 Routine Annual Maintenance

4.2 Disassembly