4 of 10

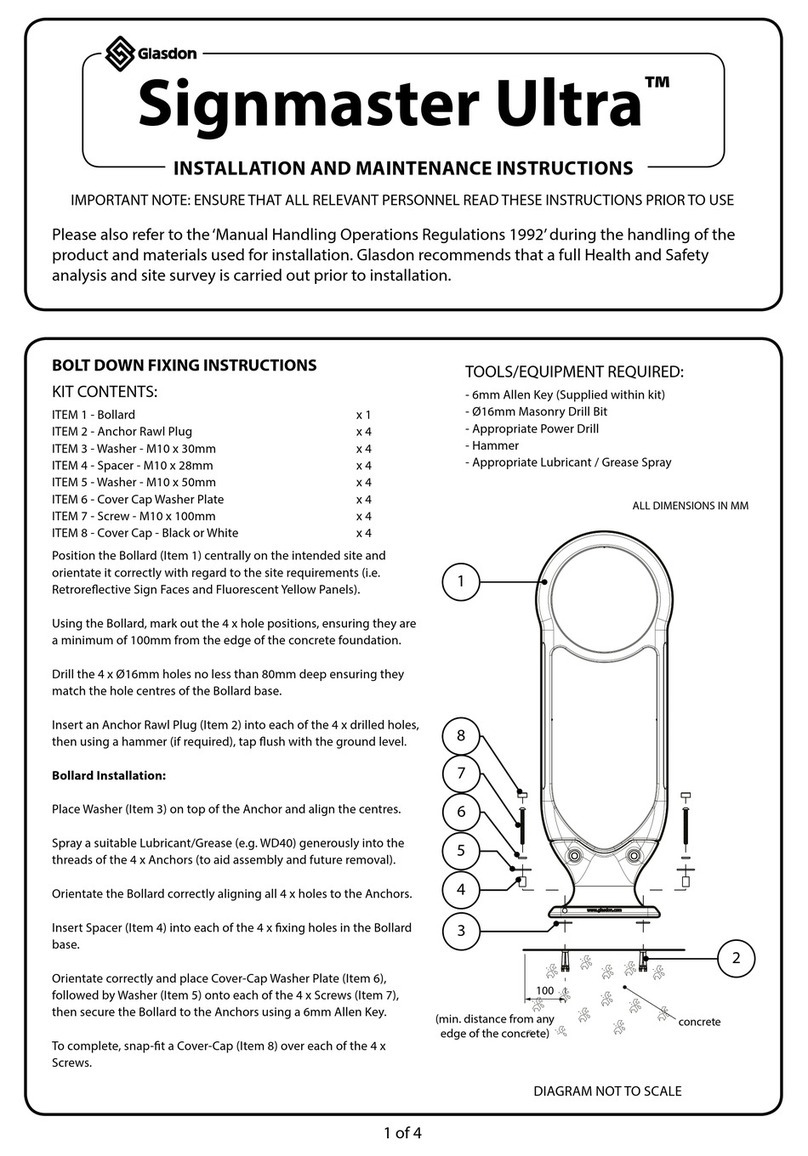

SOCKET INSTALLATION INSTRUCTIONS

1.

TYPE 1

2.

3.

5. 6.

Determine the orientation of the installation. Place the

signcarrier into the sockets (ITEM 13), determine where the

power supply source is in relation to the installation and mark

out the hole locations to suit site requirements and place the

Subsafe box (ITEM 18) in place.

Excavate x2 holes or a trench to the above dimensions for the

sockets and lay a depth of 50mm of gravel or sand in the base

of the hole for drainage.

Excavate a hole for the Subsafe to the above dimensions and

lay a depth of 50mm of gravel or sand in the base of the hole

for drainage. Adapt the excavation to suit cable entry/exit

locations and duct requirements. Choose a suitable location to

install the Subsafe relative to the signcarrier.

Excavate trenches and lay the required ducting. Between

the Subsafe and power supply source and the Subsafe to the

Orbital socket, thread the following cables: 1. Power supply

from the source to the Subsafe 2. Circuit cabling from the

Subsafe to the socket that requires the electricity supply.

Position the Subsafe box into the hole and orient to suit

direction of supply. Feed the power supply cable through the

ducting and into the gland, tighten well using a 13mm socket/

spanner and connect ducting end to unit. We recommend

leaving sucient cable inside the box to enable connection to

an IP rated cutout (not supplied).

Place the sockets into the deeper excavations. Ensure the

sockets are orientated correctly. The sockets should be

installed with the word ‘FRONT’ facing oncoming trac.

Note: Take care to avoid buried services when excavating the holes.

4.

Stem with

LED connection

13

18