concrete

320

(depth below ground)

355

(minimum depth)

100

(min. distance from any

edge of the concrete)

2 of 4

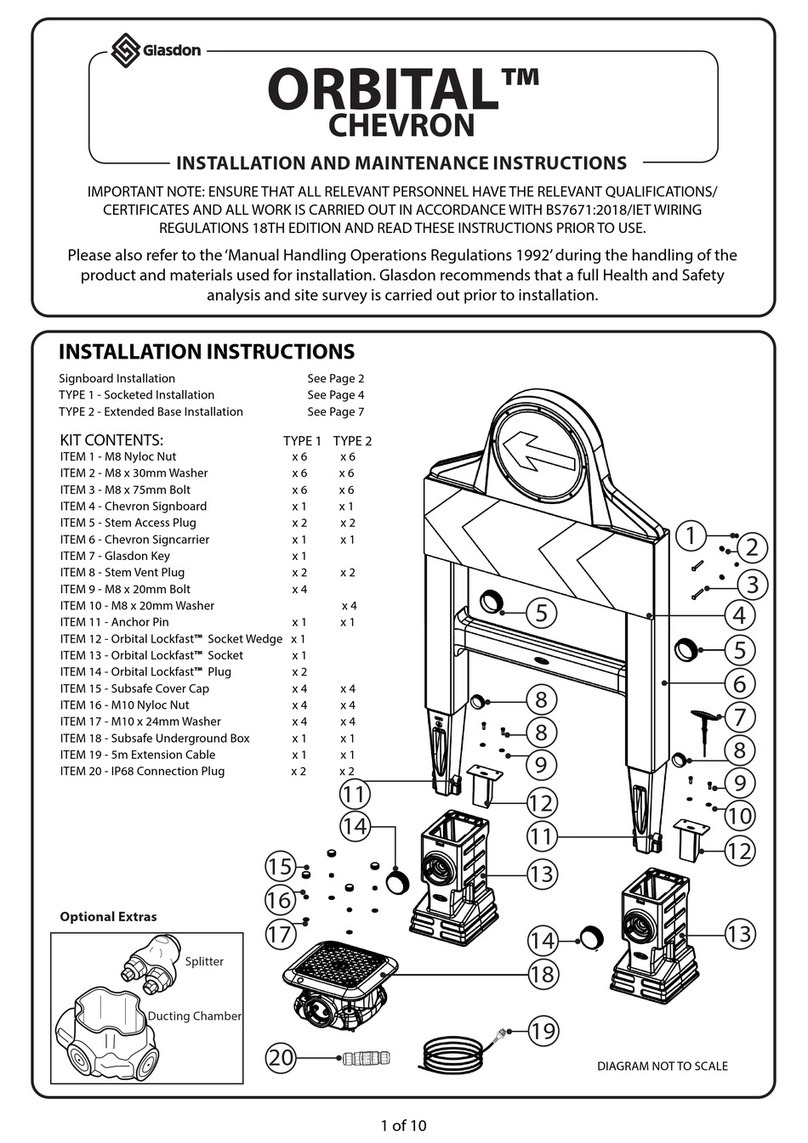

KIT CONTENTS:

ITEM 1 - Bollard (Body and Base) x 1

ITEM 2A - Adjustable Depth Concrete-in Fixing x 4

ITEM 2B - Fixed Depth Concrete-in Fixing x 2

ITEM 3 - Washer - M10 x 30mm x 4

ITEM 4 - Spacer - M10 x 28mm x 4

ITEM 5 - Washer - M10 x 50mm x 4

ITEM 6 - Cover Cap Washer Plate x 4

ITEM 7 - Screw - M10 x 100mm x 4

ITEM 8 - Cover Cap - Black or White x 4

TOOLS/EQUIPMENT REQUIRED:

- 6mm Allen Key (Supplied within kit)

- Equipment to Excavate Hole

- Concrete-Mix (Fast Setting)

- Spirit Level

- Appropriate Lubricant / Grease Spray

- Hacksaw (Optional)

1

2A

3

4

5

6

7

8

Position the Bollard (Item 1) centrally on the intended site and

orientate it correctly with regard to the site requirements (i.e.

Retroreective Sign Faces and Fluorescent Yellow Panels).

Check for buried Services before starting excavations.

Mark out and prepare a hole 430mm x 430mm x 400mm deep

(Option A), or 500mm x 500mm x 300mm deep (Option B).

Spray a suitable Lubricant/Grease (e.g. WD40) generously into

the threads of either the 4 x Adjustable Depth Fixings (Item 2A)

or the 2 x Fixed Depth Fixings (Item 2B). Then assemble these to

the base of the Bollard (Item 1) as per the diagram.

If the depth of hole is restricted to less than 400mm, the Adj-

Depth Fixings (Item 2A) can be altered by moving the bottom

washer up, then cutting the bars to the desired length with a

Hacksaw. We would recommend using the same amount of

concrete by increasing the width of the hole accordingly.

Place gravel and support blocks in the base of the prepared hole

to act as a levelling foundation for the bollard. Try the Bollard

with xings in the hole and adjust foundation accordingly until

the Bollard sits level to surrounding ground and sits vertical. Use

a Spirit Level to conrm.

Remove the Bollard from the hole and pour in the fast setting

Concrete mix to the desired level.

Orientate Bollard correctly with regard to the site requirements

(i.e. Retroreective Sign Faces and Fluorescent Yellow Panels),

then place into the hole ensuring the base is ush with the top

surface of the Concrete.

Ensure the Bollard remains vertically level during the concrete

setting period. The use of a spirit level is highly recommended.

Leave to set.

concrete

250

(depth below ground)

100

(min. distance from any

edge of the concrete)

2B

A - ADJUSTABLE DEPTH

B - FIXED DEPTH

DIAGRAM NOT TO SCALE

CONCRETE-IN FIXING INSTRUCTIONS

ALL DIMENSIONS IN MM

For speed we recommend installing with quick setting

concrete (e.g. Grade QC10) but exact installation

requirements should be assessed from a site survey.