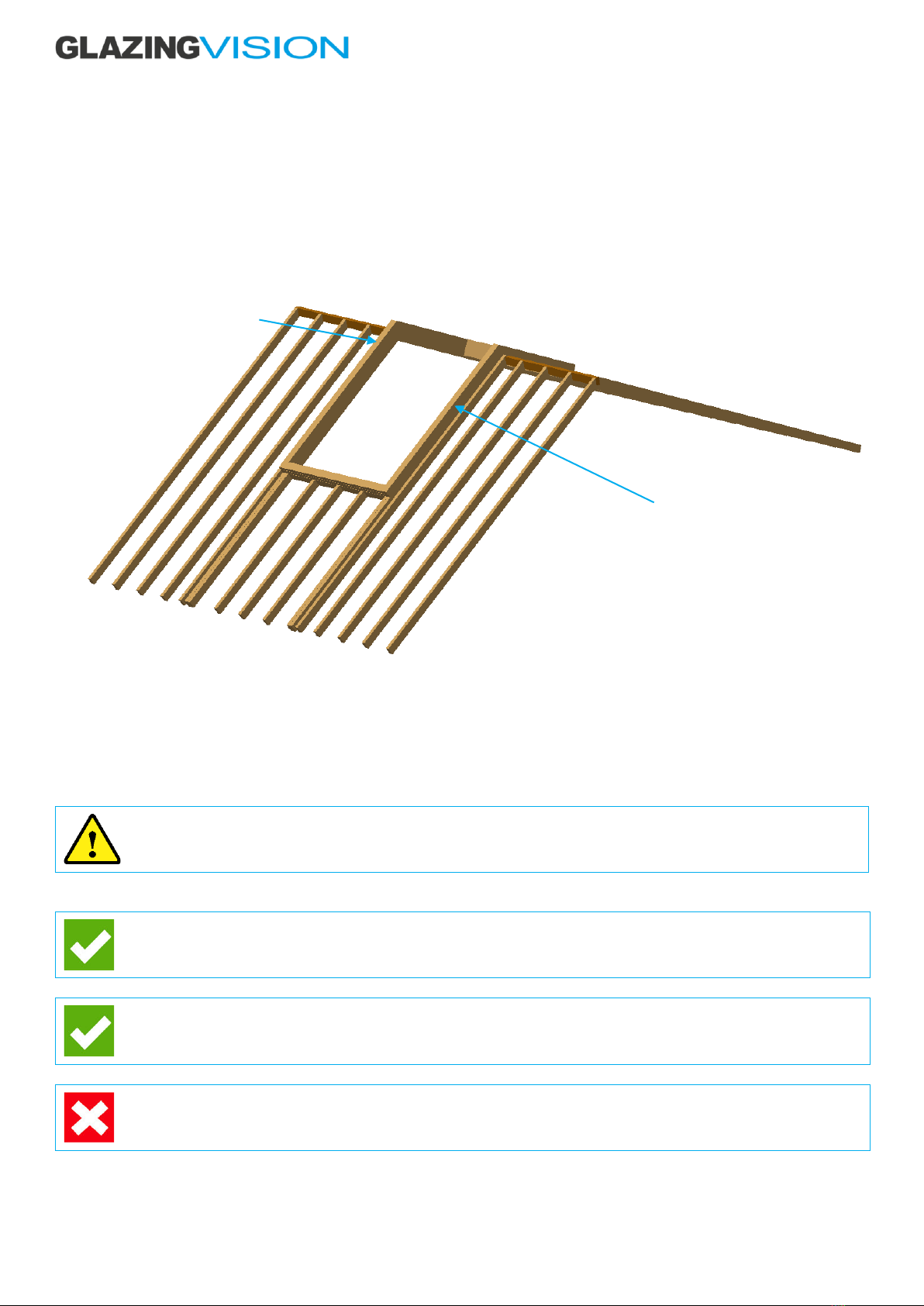

3. The supporting structure must already be in place for the product. The dimensioning of the product will have taken into

consideration the dimensions of the supporting structure including all weathering. More information about supporting

structure construction can be found in Glazing Vision’s sales drawings. Please note that a minimum distance of 140mm

from the structural opening to any surrounding structured must be felt on all sides. Sufficient room for installation

(including weathering) and maintenance must also be allowed for.

4. It is important to consider the type of tile or other roof finish to be used. The opening in the roof should ideally be positioned

so that you get a full tile at the top and at the bottom of the product, avoiding the need to cut tiles down.

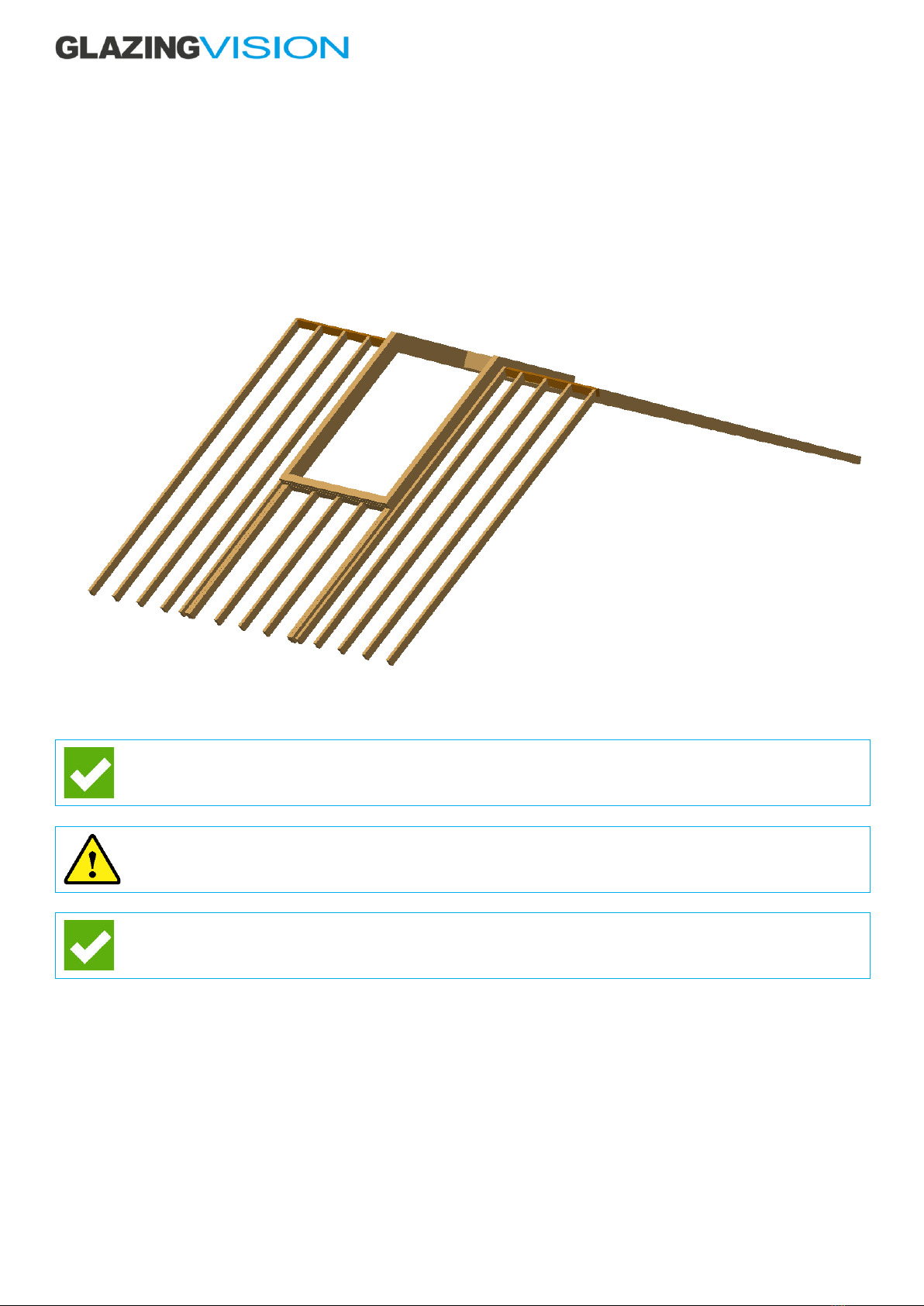

5. It is important to ensure that the area of installation is suitably prepared. The area surrounding the supporting structure

should be clear to provide safe access during the installation works. It will be necessary to work on the outside and

therefore suitable provisions should be made for safe handling of the product, including all relevant personal protective

equipment (PPE) and safety systems for working at heights.

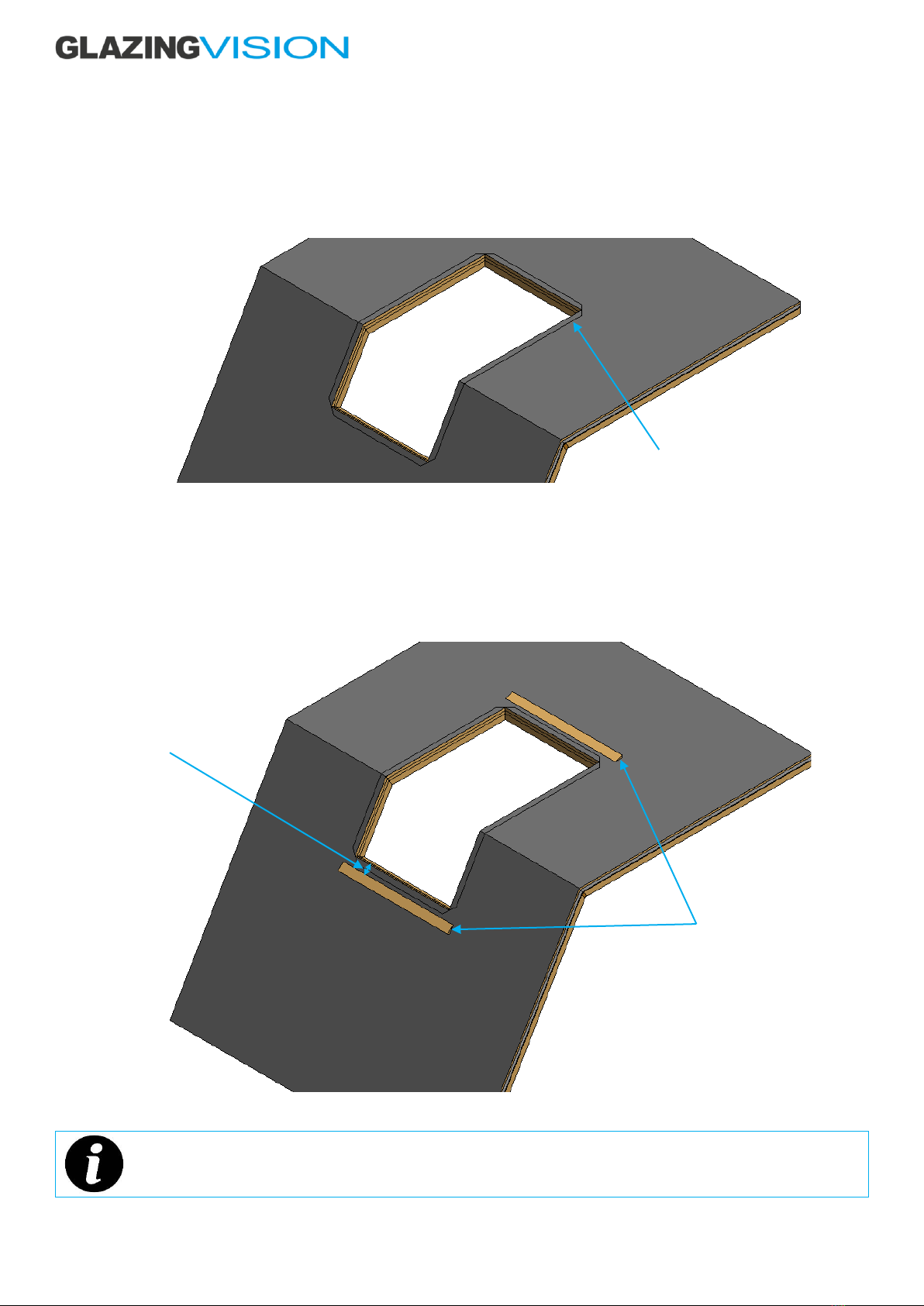

6. Before starting installation, Glazing Vision advises that the physical supporting structure dimensions are cross-checked

with those given for the order, to ensure the product will fit. The supporting structure will need to be within ± 10 mm of the

ordered size (measured across the flats). The top surface of the supporting structure should be flat without undulations

greater than ± 2 mm. Also check the diagonals to ensure that the supporting structure has been constructed square. The

supporting structure must be weathered as per the sales drawings. If using any metallic waterproofing material, take care

when applying it to the product/supporting structure, as if done incorrectly it can cause a thermal bridge which can lead

to internal condensation and invalidate the product warranty.

7. These products can be very heavy. Glazing Vision strongly recommends that a structural engineer is consulted when

designing the structure(s) that will support the product and the surrounding structure. Nothing in this manual or on Glazing

Vision’s sales drawings constitutes a structural proposal.

8. Preparation of the roof prior to installation will vary depending on roof type and roofing materials. A few common scenarios

are included in this manual. Please follow the applicable steps for your configuration. Glazing Vision strongly recommends

that a ‘dry run’ (without any silicone or butyl) is completed before committing to the final installation.

Sales Drawings

Sales drawings for the Pitchglaze can be obtained by downloading them from Glazing Vision’s website

(www.glazingvision.co.uk/resources) or by contacting Glazing Vision.