Need assistance? +44 (0)1379 658300 info@glazingvision.co.uk Page 7 of 19

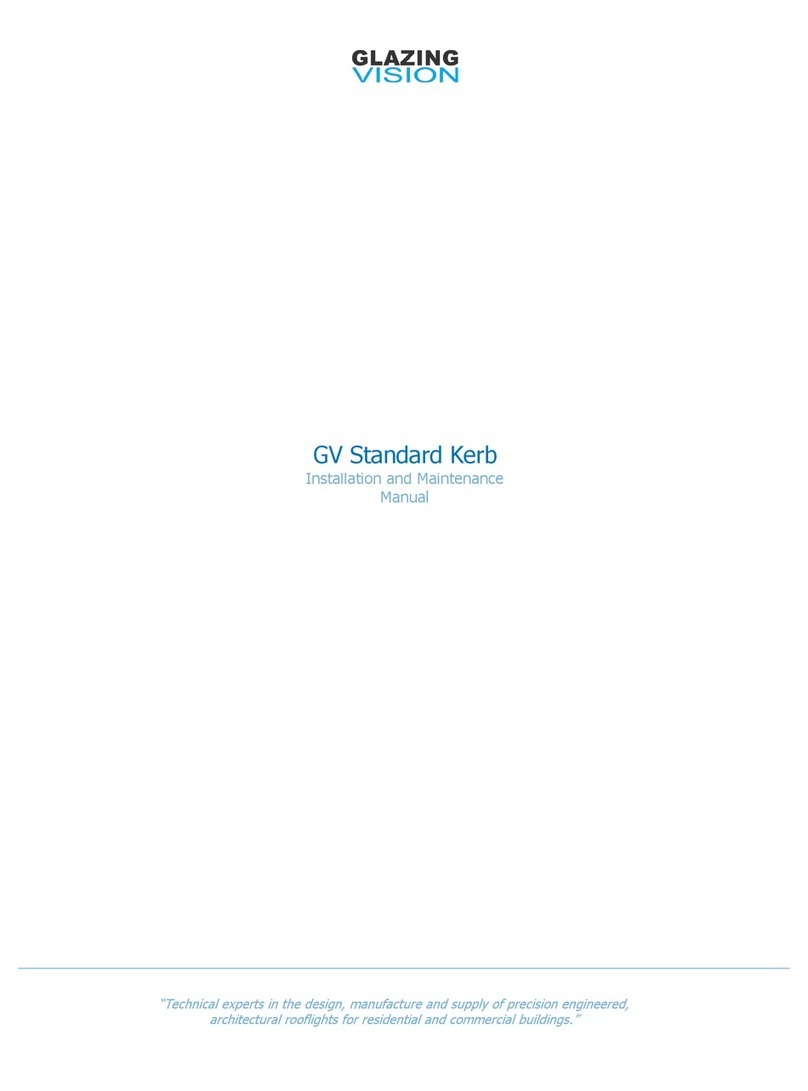

Pairing a Remote Control

Additional remote controls can be paired to or unpaired from the product. To put the product into pairing mode and prepare it for

adding or removing a remote control follow these steps:

1. Ensure that the product is fully closed.

2. Press and hold the CLOSE (down arrow) button on the wall-mounted control switch.

3. Still holding the CLOSE button, press and hold the OPEN (up arrow) button.

4. As soon as the status light starts flashing, release both buttons.

The control switch status light will now flash red and blue alternately for 2 minutes. You now have a 2-minute window in which to

pair the remote to the product.

To Add a Remote

Press any of the buttons on the remote control during the 2-minute pairing window. Wait for approximately 30 seconds and then

press either the open or close buttons (this needs to be done before the 2 minutes are up). The remote control should now be paired

to the product. When using the remote control its status light will illuminate green when the product is in motion.

To Delete a Remote

Ensure there has been at least 2 minutes since either the product was first powered up or from when the pairing procedure was

initiated (i.e. you are not in the 2-minute pairing window). Press all three buttons on the remote control together and immediately

release them. The status light on the remote control should turn red for a few seconds and then turn off. If it turns green or amber,

try pressing the three buttons again. When the red status light turns off, the remote will be unpaired from the product.

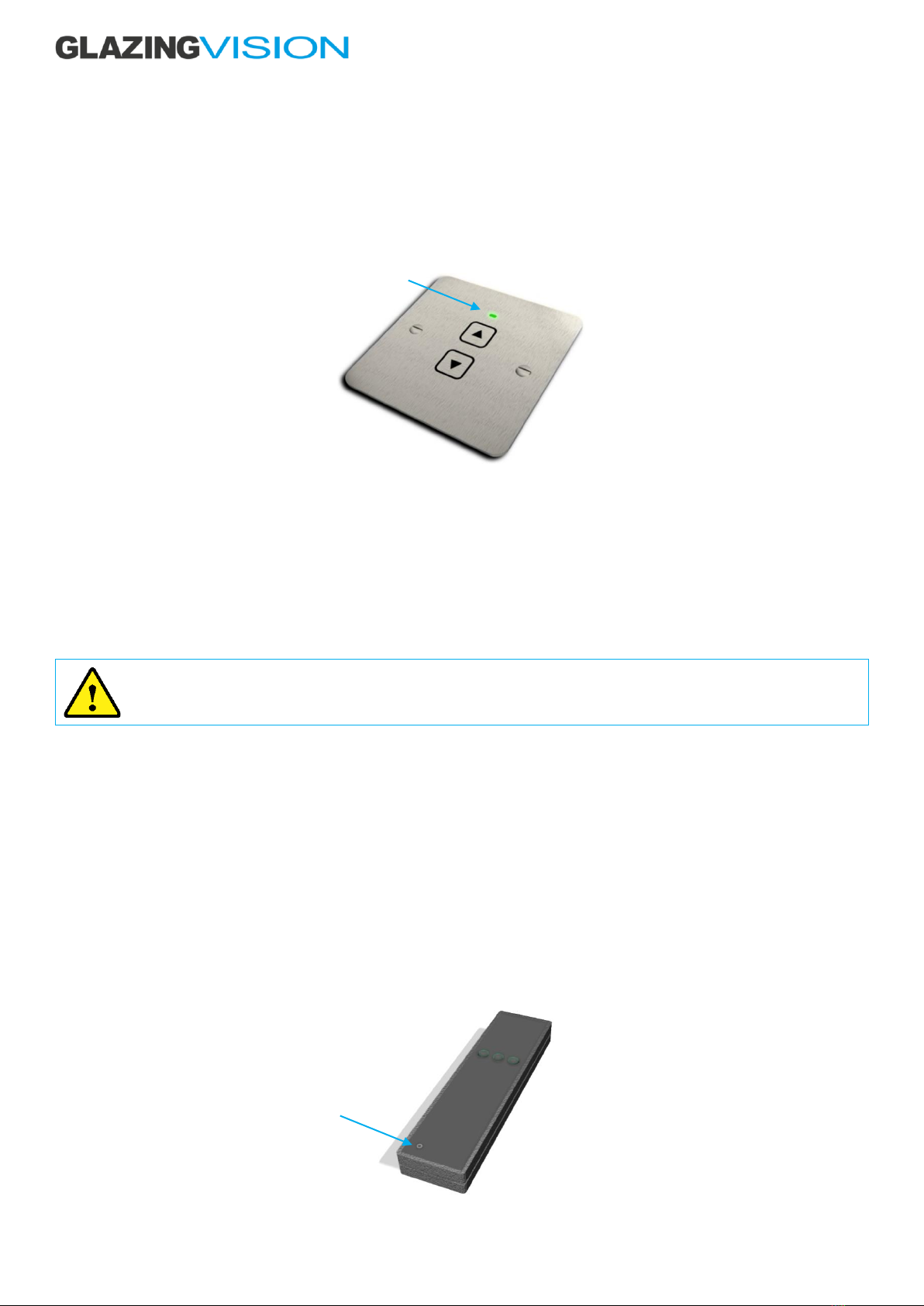

Rain Sensor (Optional)

The rain sensor automatically closes the product when moisture is detected. The status light illuminates green when moisture is

detected and remains green for several minutes. The rain sensor will try to close the product every 60 seconds while the green light

is illuminated. The control switch status light will also flash intermittent green indicating a closure due to rain. The rain sensor is

switched off once the product is completely closed.

The rain sensor should be positioned horizontally (parallel to the ground) in a location that will ensure that it is exposed to the rain

and must be kept clean to function correctly.

Figure 3 –Rain sensor

Rain Sensor Isolation Switch (Optional)

The rain sensor isolation switch is internally mounted and wired directly to the rain sensor cable, allowing the sensor to be switched

on/off. Turning off the switch deactivates the signal from the rain sensor and prevents the product from closing in the event of rain.

This avoids the scenario where someone could be shut outside by the rain sensor when it rains. Ensure that the switch is turned

back on for normal use.

Figure 4 –Rain sensor isolation switch