Rev. 0-599 Model D53 D.O. Analyzer (universal-mount 1/2 DIN)

5

CONDENSED OPERATING INSTRUCTIONS

This manual contains details for all operating aspects of the instrument. The following condensed in-

structions are provided to assist you in getting the instrument started up and operating as quickly as

possible. These condensed instructions only pertain to basic dissolved oxygen measurement op-

eration (in ppm). To use specific features of the instrument, refer to the appropriate sections in this

manual for instructions.

A. CONNECTING SENSOR(S)

The analyzer can always be used with one sensor connected to SENSOR A terminals. When the

analyzer is equipped with the optional two sensor input software, a second sensor can be connected

to SENSOR B terminals and used for monitoring.

1. After the analyzer is properly mounted (Part Two, Section 2), install the GLI membrane dissolved

oxygen sensor(s). Refer to the sensor instruction manual for details.

2. When using GLI mounting hardware, plug the sensor cable into the mating receptacle on the

junction box. Route the 6-conductor interconnect cable (GLI part number 1W1100) from the

junction box to the analyzer.

3. At the analyzer end of the interconnect cable, twist the two shield wires together. Then insulate

them with plastic tubing or tape to prevent inadvertent shorting, and connect the combined shield

to one of the 5 open holes on the grounding strip at the bottom of the analyzer case (Figure 2-3).

4. Connect the other interconnect cable wires to the analyzer SENSOR A terminals on TB1,

matching colors as indicated:

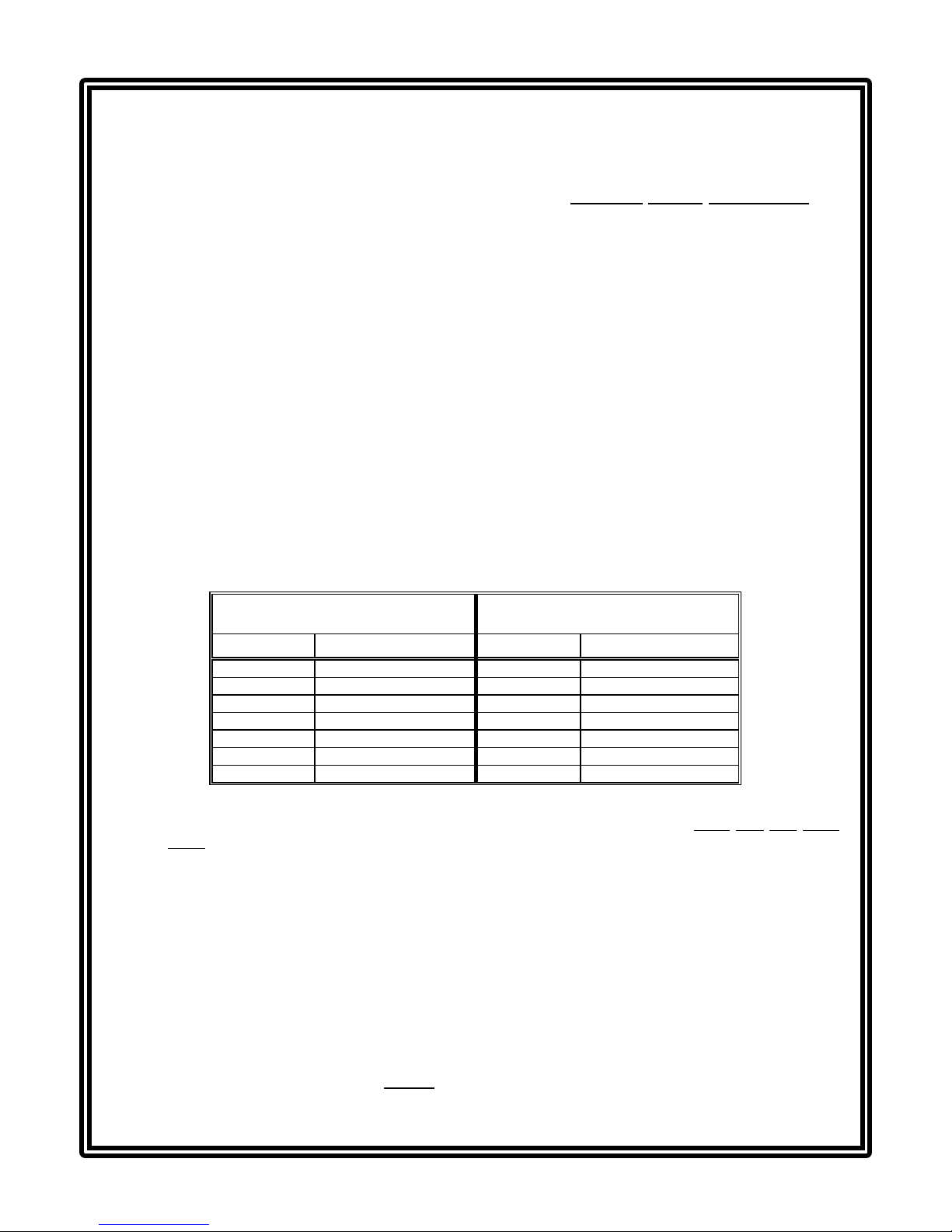

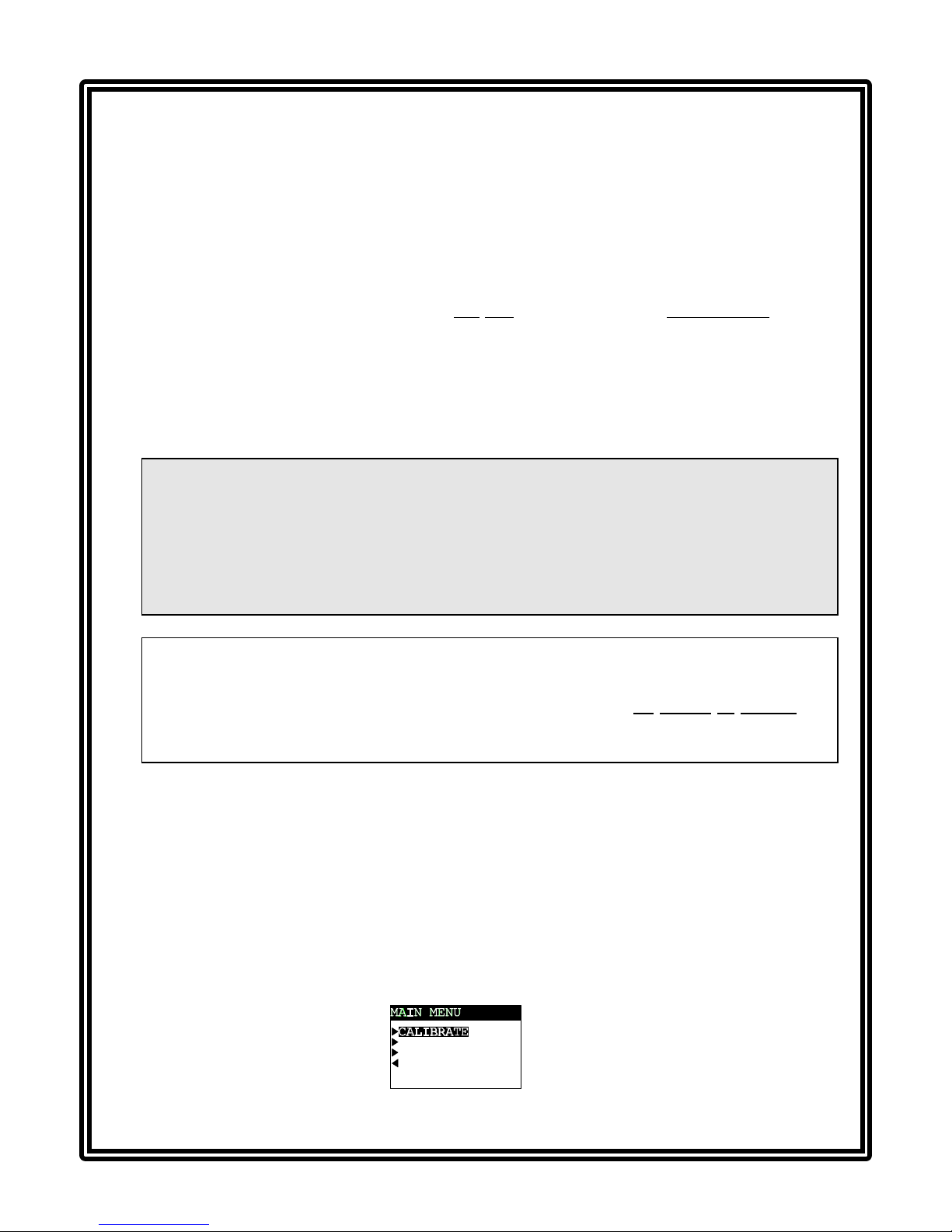

Sensor A

Interconnect Cable Connections Optional Sensor B Input

Interconnect Cable Connections

Wire Colors At Analyzer Terminals Wire Colors At Analyzer Terminals

Red #10 on TB1 Red #16 on TB1

Green #11 on TB1 Green #17 on TB1

Blue #12 on TB1 Blue #18 on TB1

White #13 on TB1 White #19 on TB1

Black #14 on TB1 Black #20 on TB1

Yellow #15 on TB1 Yellow #21 on TB1

Cable shields Grounding strip lug Cable shields Grounding strip lug

5. At the junction box end of the interconnect cable, twist the two shield wires together. Then con-

nect the combined shield to the junction box terminal corresponding to the white wire with black

stripe. Connect the other interconnect cable wires to terminals corresponding to their wire colors.

NOTE: When the analyzer is equipped with the optional sensor quick-disconnect receptacle(s),

simply plug the sensor cable(s) into them. This eliminates using the junction box supplied

with GLI sensor mounting hardware, and the need for interconnect cable.

B. CONFIGURING SENSOR TEMPERATURE ELEMENT(S)

The analyzer is supplied factory-set for automatic temperature compensation using the NTC 30K

ohm thermistor element built into GLI membrane dissolved oxygen sensors. For fixed manual tem-

perature compensation, you must change the temperature element type to “MANUAL” (see Part

Three, Section 4.3, subheading “Selecting Temperature Element Type”) and enter a temperature.

NOTE: When the analyzer is equipped with the optional two sensor input software and only one

sensor is being used, the unused sensor input must be set for “MANUAL” compensation to

prevent a “WARNING: CHECK STATUS” message from appearing.

(continued on next page)