•Pageglobalcontract.com 3

• Summer 2017

GLOBALContract

INSTALLATION GUIDELINES

Panel Connector

Every panel ships with a connecting kit comprising hinges, spacers, screws and hinge

pins. Not all pieces included in the connecting kit might get used with every panel (con-

necting two stand alone panels at 90°, for example, will only require installation of two

hinge / spacer sets at the top and bottom of each panel). The remaining pieces included

in the connecting kit should be stored on site to be available for future reconfigurations.

Location of connecting hinge / spacer and hinge / hinge set on panels is predetermined

by location of double holes, pre-drilled in panel verticals. There are pairs of holes located

always at the panels’ bottom and top. In addition, a 54” high panel will have a pair at 42”

height (to connect to 42” high adjacent panel) and a 66” high panel will have additional

pairs at 42” and 54” height (to connect to 42” and 54” adjacent panels).

NOTE: When connecting 66” high partly glazed panels, use additional set of connectors

at 42” height.

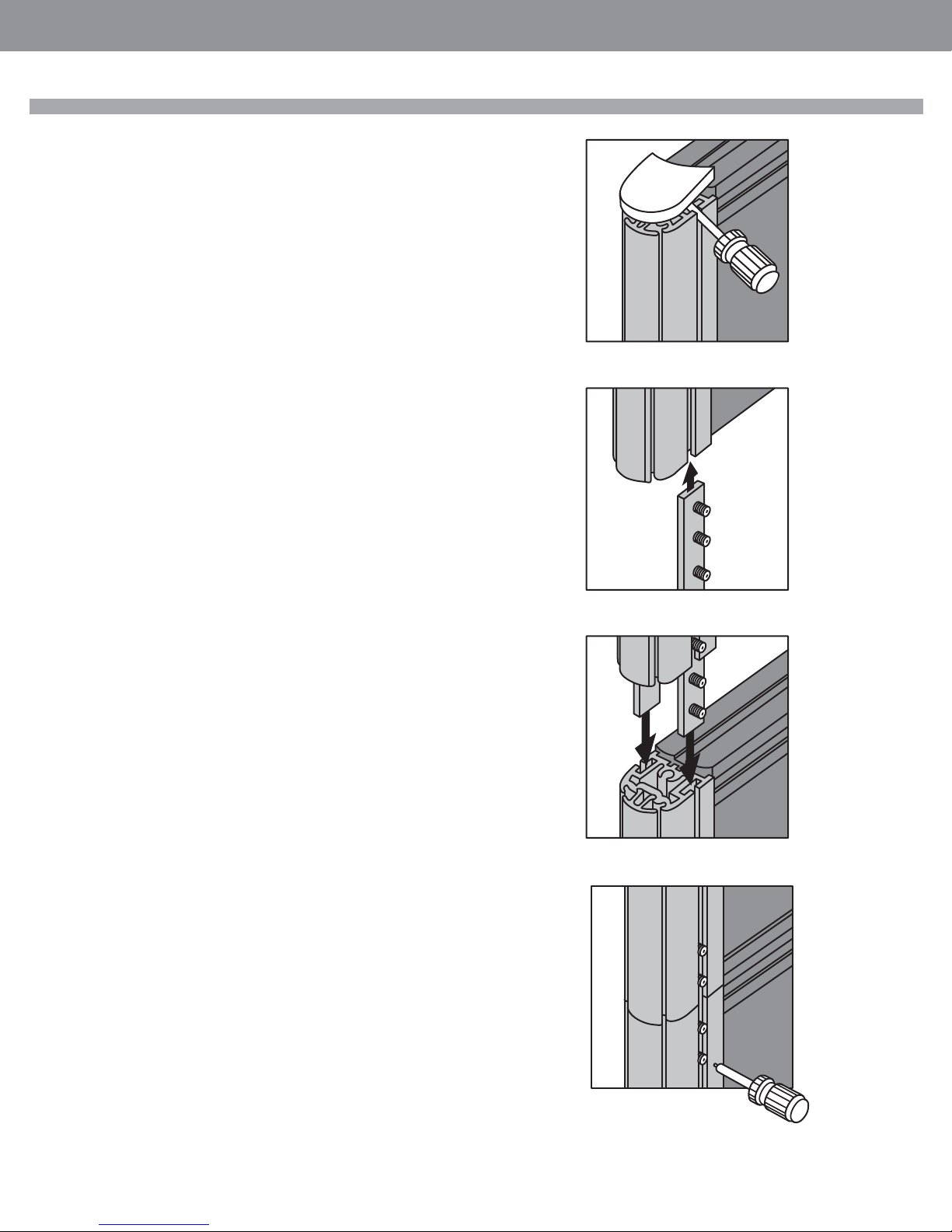

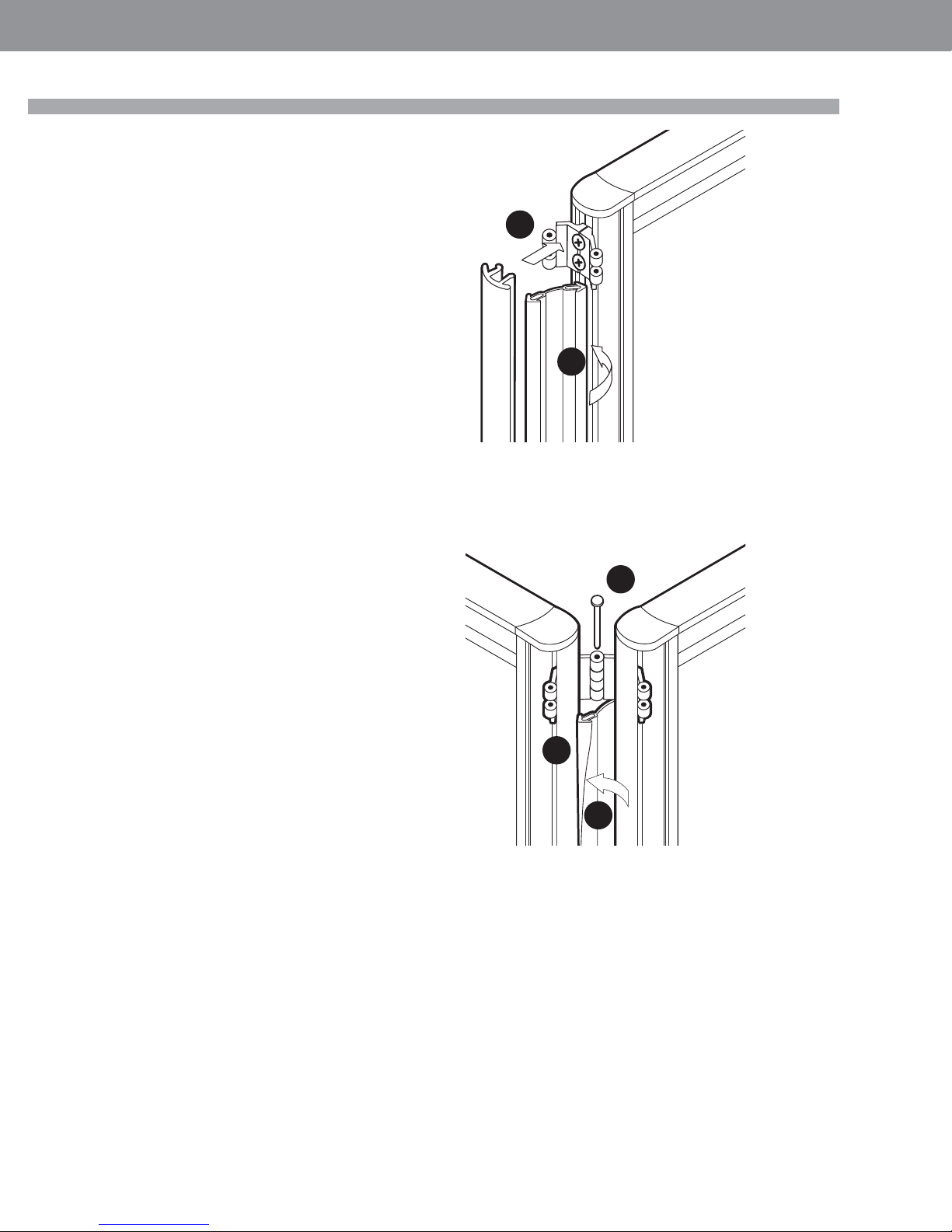

In order to install panel connectors to connect two panels at flexible angle,

STEP 1: remove vertical edge trim,

STEP 2: position spacer A and hinge B over pre-drilled holes at desired height,

STEP 3: secure with two supplied screws (Do not over tighten!) and snap the

vertical edge trims back in place.

Set the panels to desired angle. Insert top and bottom pins. In order to connect two

straight panels (180°),

STEP 4: Remove vertical edge trims, position two hinges over pre-drilled holes at

desired height and secure with two supplied screws on both panels. Do

not over tighten! Snap vertical edge trims back in place.

STEP 5: Level the first panel, position the second panel so that all hinges overlap

and insert four pins (two at the top; two at the bottom).

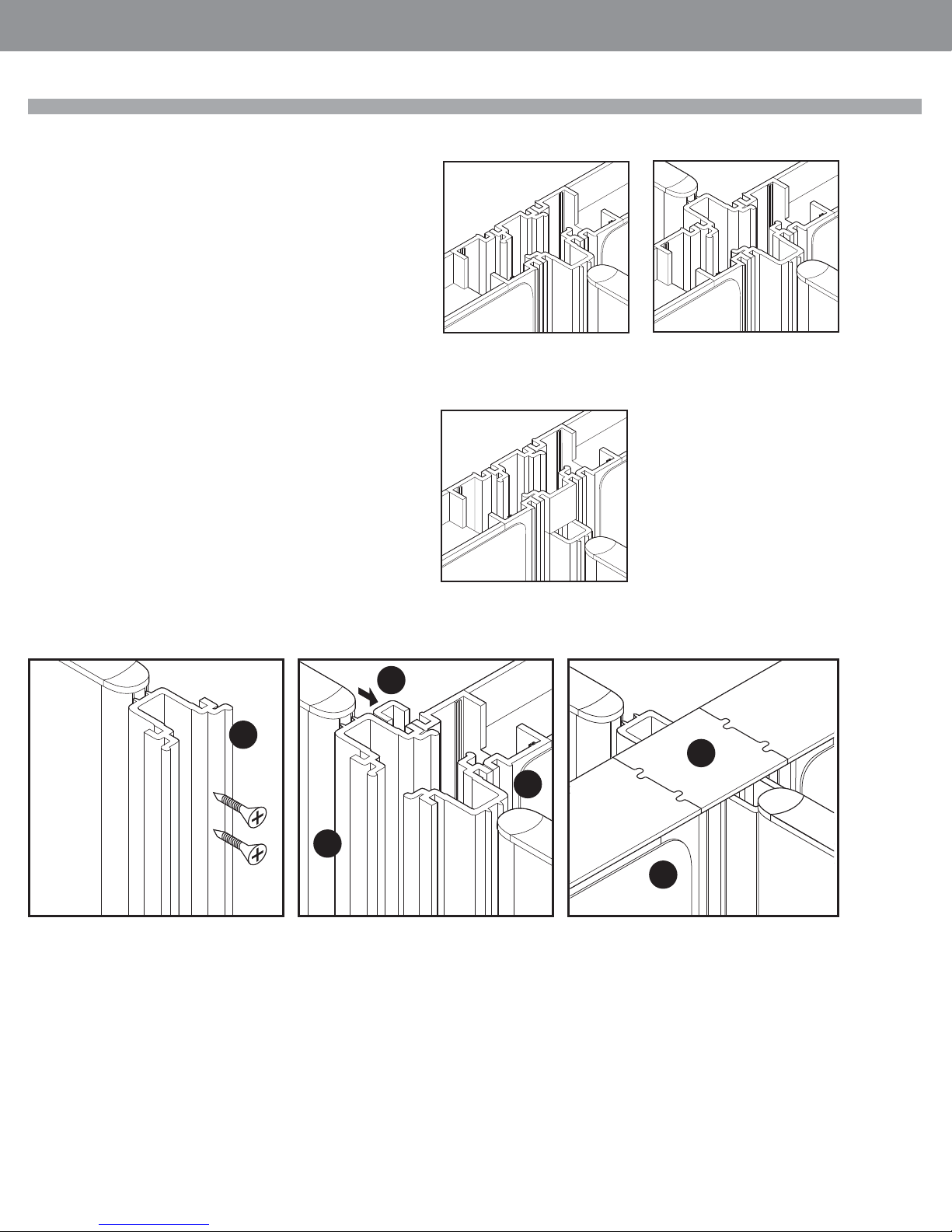

STEP 6: To connect 3 panels in a 90°, 3 way configuration, remove panel vertical

edge trims and install two spacer / hinge sets (top and bottom) on both

wing panels.

Install two hinge / hinge sets (top and bottom) on the panel that is going

to be installed between the wing panels.

Replace vertical edge trims, level the first panel, position wing panels so

that all hinges overlap and insert four pins (two at the top; two at the

bottom) as you go along.

STEP 7: To connect three panels in a 120°, three-way configuration (or four

panels in a 90°, four-way configuration.

Remove panel vertical edge trims and install two hinge / hinge sets (top and bot-

tom) on all panels.

Replace vertical edge trims, level the first panel, position remaining panels so that

all hinges overlap and insert four pins (two at the top; two at the bottom) as you

go along. Level the whole panel assembly.

1

4

5

6

2

3

B

A