- 1 -

INTRODUCTION

1 Instructions guidance.........................................................................................................................3

1.1 Product documentation...........................................................................................3

1.2 Associated documents ...........................................................................................3

1.3 Explanation of symbols...........................................................................................3

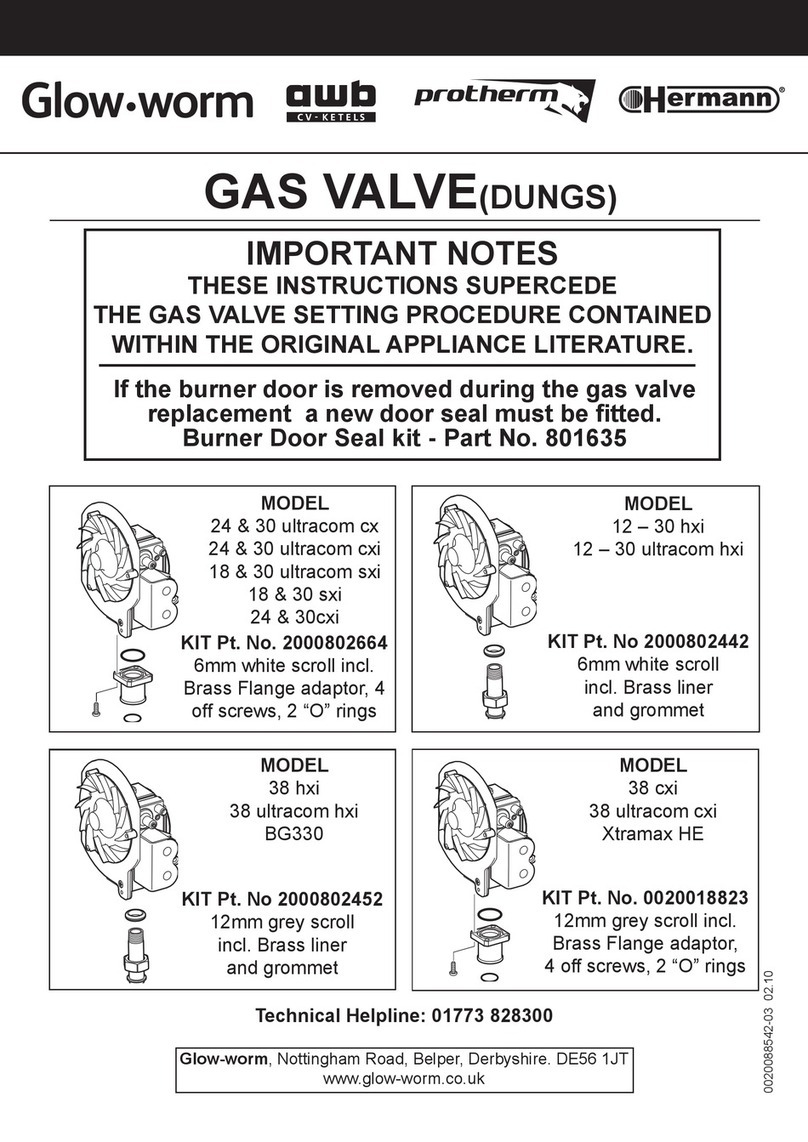

2 Product description ............................................................................................................................3

2.1 Regulation and statutory requirements ..................................................................3

2.2 Block diagram.........................................................................................................3

3 Safety instructions and regulations....................................................................................................3

3.1 Safety instructions ..................................................................................................3

3.2 Regulations.............................................................................................................4

4 Recycling ...........................................................................................................................................4

4.1 The equipment........................................................................................................4

4.2 Packaging...............................................................................................................4

INSTALLATION

5 Control unit location ...........................................................................................................................5

6 Installation..........................................................................................................................................5

6.1 Dimensions.............................................................................................................5

6.2 Scope of delivery....................................................................................................5

6.3 Installation ..............................................................................................................6

7 Electrical connections .......................................................................................................................7

7.1 External connection................................................................................................7

7.2 Internal connection .................................................................................................8

7.3 Electrical connections.............................................................................................8

8 Commissioning ..................................................................................................................................9

9 Installation menu..............................................................................................................................10

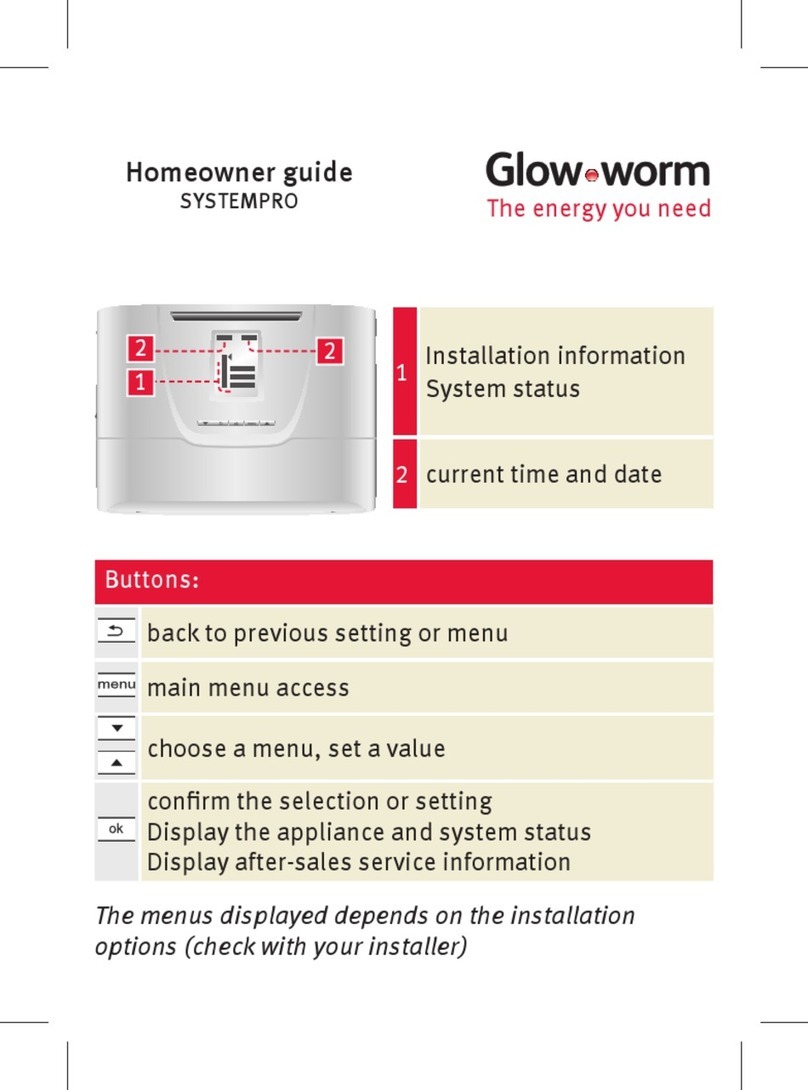

9.1 Description of buttons...........................................................................................10

9.2 Access to the installation menu............................................................................10

9.3 Description of the installation menu .....................................................................10

9.4 Installation ............................................................................................................10

9.5 Thermostat and sensor.........................................................................................10

9.6 Automatic test....................................................................................................... 11

9.7 Parameters...........................................................................................................12

9.8 Commissioning.....................................................................................................12

9.9 Component information ........................................................................................12

9.10 Options .................................................................................................................13

10 Specific adjustment..........................................................................................................................13

10.1 Resetting the control unit......................................................................................13

11 Re-check and restart........................................................................................................................13

12 User information...............................................................................................................................13

TABLE OF CONTENTS