4

K129e

JAN 2014

INSTALLATION

Protect pressure-relief valves from dirt and moisture.

Match capacity on valve nameplate to system document

as specified by system designer and based upon

protected vessel size. Mount valve directly at the vapor

space of pressure vessel or on connecting non-valved

vapor piping as close to the vessel as possible. (Model

EZLQ liquid relief valves can be connected where

liquid is to be expected and relieved to a similar or

lower pressure, not to exceed the set pressure of the

relief valve. Generally, the relief valve is piped around

the isolation valve of the protected section or vessel).

EZ-SRV™ Cartridge pressure-relief valves should be

installed upright.

Never expose your face or body to a connected relief

valve exit or piping.

Check that the valve setting and capacity (see Nameplate

Information Section) meets the requirements per

system design in accordance with local and national

regulations. Isolate the valve and related piping from

the refrigeration system and pump out pressure to zero

before attempting to install or replace any pressure-

relief valve. Use appropriate safety equipment. Avoid

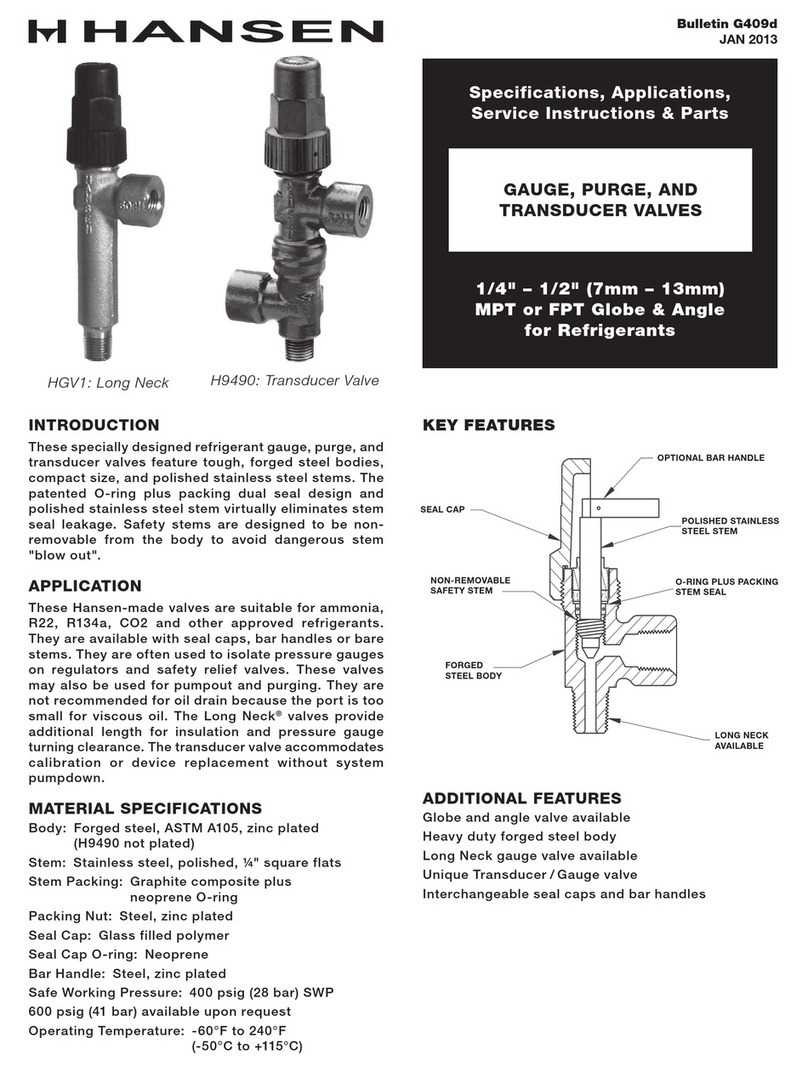

residual refrigerant when doing so. A gauge valve and

gauge can be installed in the inlet pressure port for

future use to verify and control any refrigerant which

might remain. See also Gauge Valves and Pressure

Gauges section on page 6.

Remove shipping caps from the EZ-Fitting. Thread or

weld EZ-Fitting into the pressure vessel or three-way

dual shut-off valve at a location in the vapor space

above the liquid refrigerant level. Install the EZ-SRV™

cartridge pressure-relief valve into the EZ-Fitting and

tighten to approximately 75 foot–lbs (102Nm). These

valves are for gas relief only. (For liquid relief, Hansen

offers the EZLQ relief valve specifically designed for

liquid, refer to page 6). Do not install shut-off valves in

line with pressure-relief valves. Install valves in locations

where they will not be damaged by moving equipment

such as lift trucks, etc. Install valves in a manner that

enables them to be replaced.

When a dual pressure-relief system is being put into

service, the three-way valve stem should be positioned

so that only one valve is exposed to pressure. While

the three-way valve can be either frontseated (front

port is closed) or backseated (back port is closed), the

backseated position is recommended because it takes

pressure off the packing and reduces the possibility of

packing leaks.

Vent the relief valve exit to a safe outdoor location in

an approved manner away from people and building

openings. Do not install valves or vent piping in a

refrigerated space unless precautions are taken to

prevent moisture migration into the valve body or the

relief vent line. Avoid trapped ice build-up between

valves and other equipment.

Only apply thread sealing compound to external pipe

threads and use a modest amount to avoid getting

compound inside the valve. Use brackets or hangers

to support the pipe and prevent the valve from being

overly stressed. Do not put undue stress on the valve

by using it to stretch or align pipe.

Pressure test all valves and related piping for leaks.

When testing a dual pressure-relief system, the three-

way valve stem should be in the mid position (only during

testing), ensuring that all valves are properly leak tested.

Do not discharge valves prior to installation or when

pressure testing. Never attempt to reset or change the

valve setting. Always replace cartridge pressure-relief

valves once they have discharged.

Hansen EZ-SRV™ valves come with an installation date

tag to identify the number of years the valve has been

in service. When installing the EZ-SRV™ valve, remove

the knockouts corresponding to the current year and

month. Use a pen to push the knockout partially through

the tag and tear away from other side.

Pressure-relief valves for ammonia refrigeration are

subject to preventative inspection and maintenance or

periodic replacement. Normal replacement is five years

from installation. However, once a valve discharges it

must be replaced as soon as possible. Self-reseating is

not dependable because of the possibility of dirt lodging

on the seat surface allowing the valve to leak or “weep”.

REPLACING EXISTING RELIEF VALVES

EZ-SRV™ cartridge pressure-relief valves have the

same capacity as the Hansen H5600 “R” series relief

valves. The Hansen EZ-Adapter is available to make

the inlet and outlet connection dimensions the same

as the Hansen H5600 series. This minimizes piping

changes to the discharge line connections. The EZ-

Adapter provides the same centerline dimensions as an

H5600 series relief valve installed with a 2˝ long nipple.

½˝ EZ-Adapter, p/n 40-0331. ¾˝ EZ-Adapter, p/n 40-0332.

OUTLET

INLET

OUTLET