Graco E-Flo B Series Parts list manual

Other Graco Control Unit manuals

Graco

Graco 297825 User manual

Graco

Graco SDM8 Series User manual

Graco

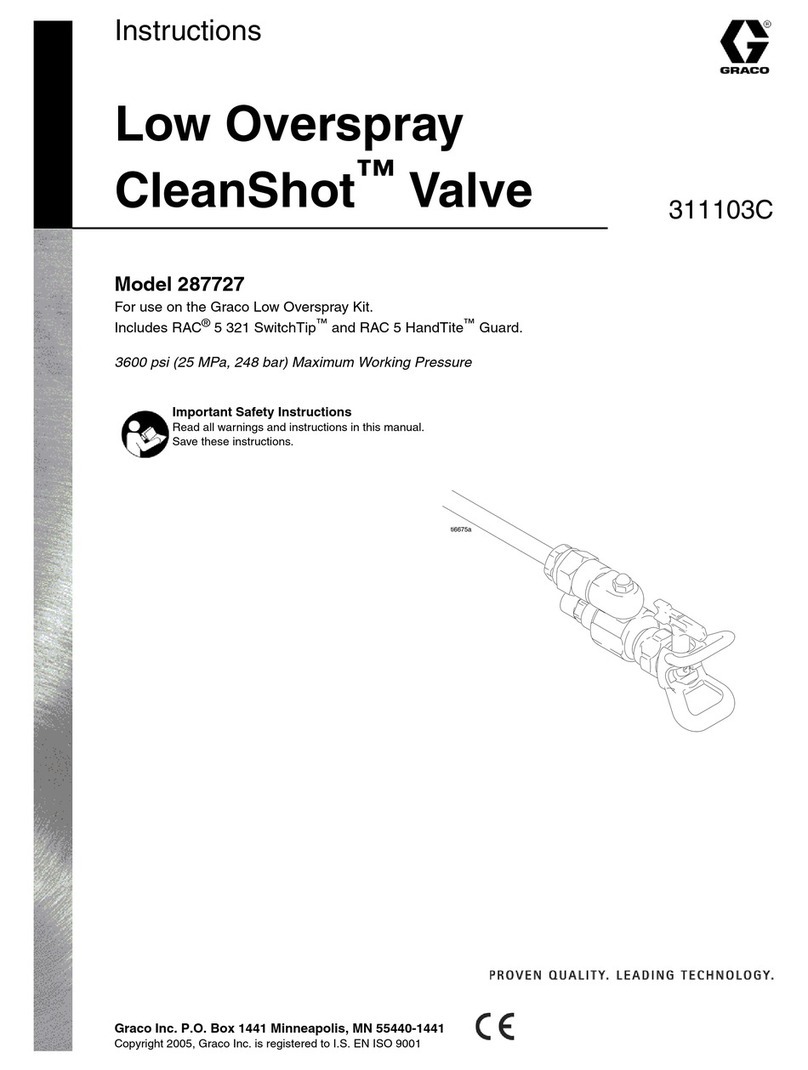

Graco CleanShot 287727 User manual

Graco

Graco 26D274 User manual

Graco

Graco SDP8 Series Owner's manual

Graco

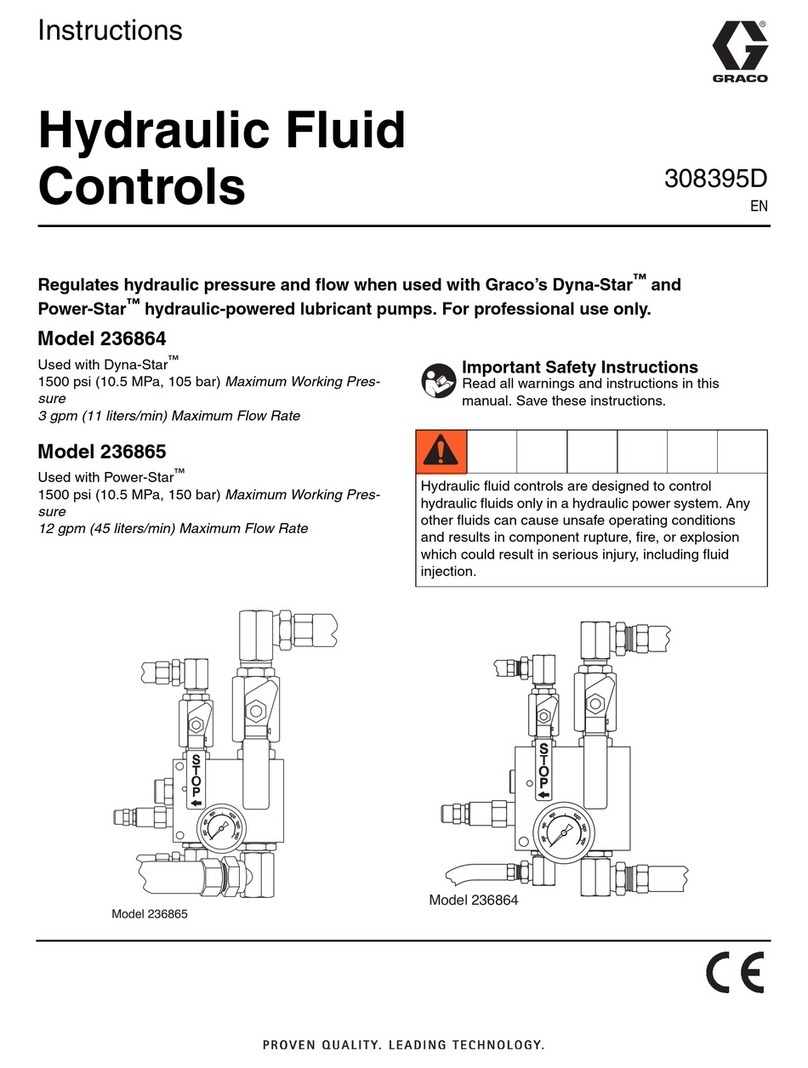

Graco Dyna-Star 77X540 User manual

Graco

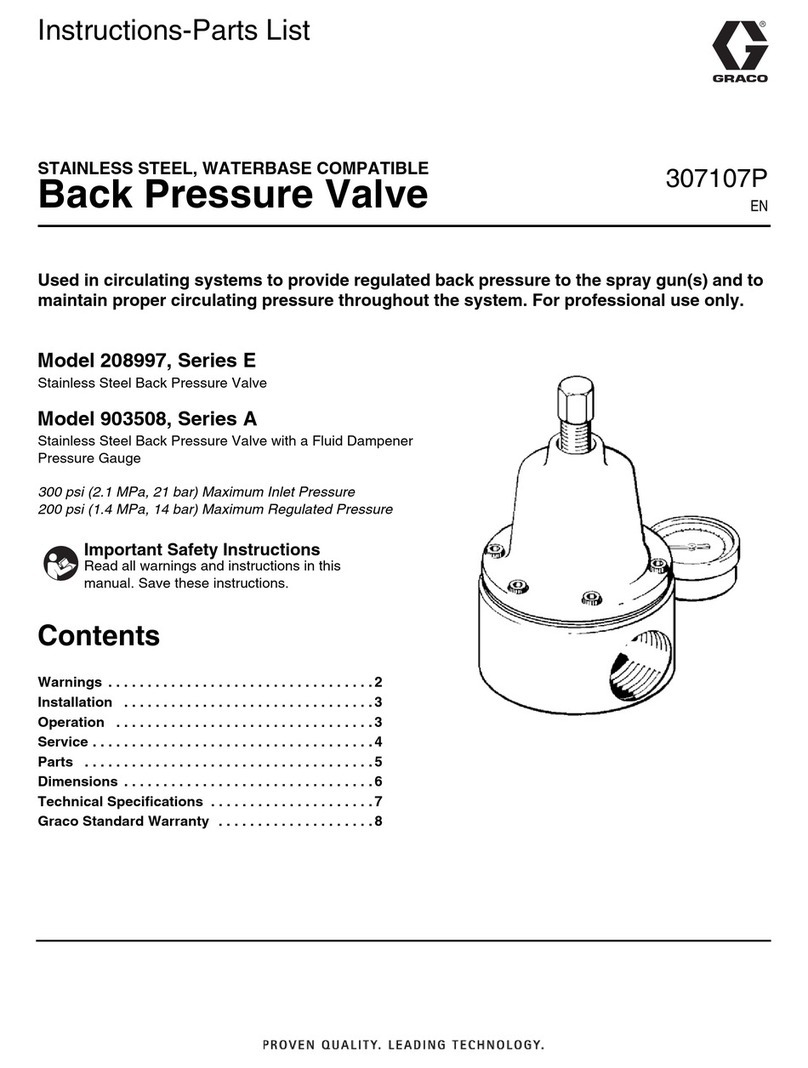

Graco E 208997 Operation manual

Graco

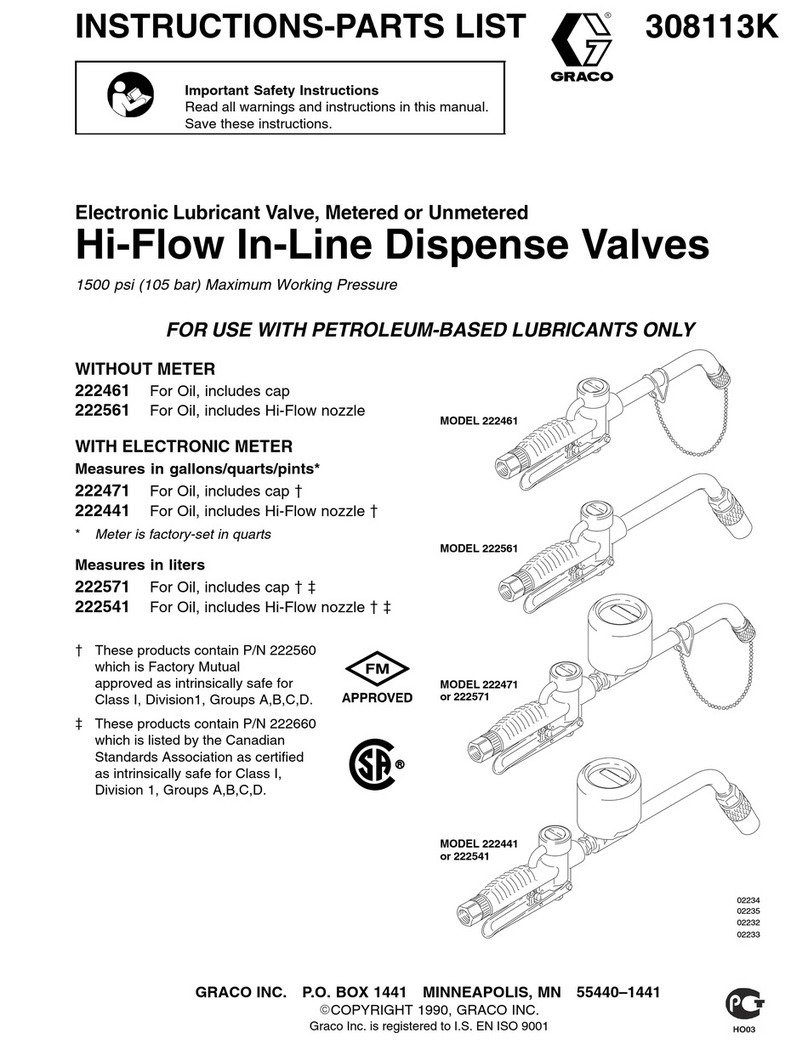

Graco 222461 Operation manual

Graco

Graco EM5 Series Operation manual

Graco

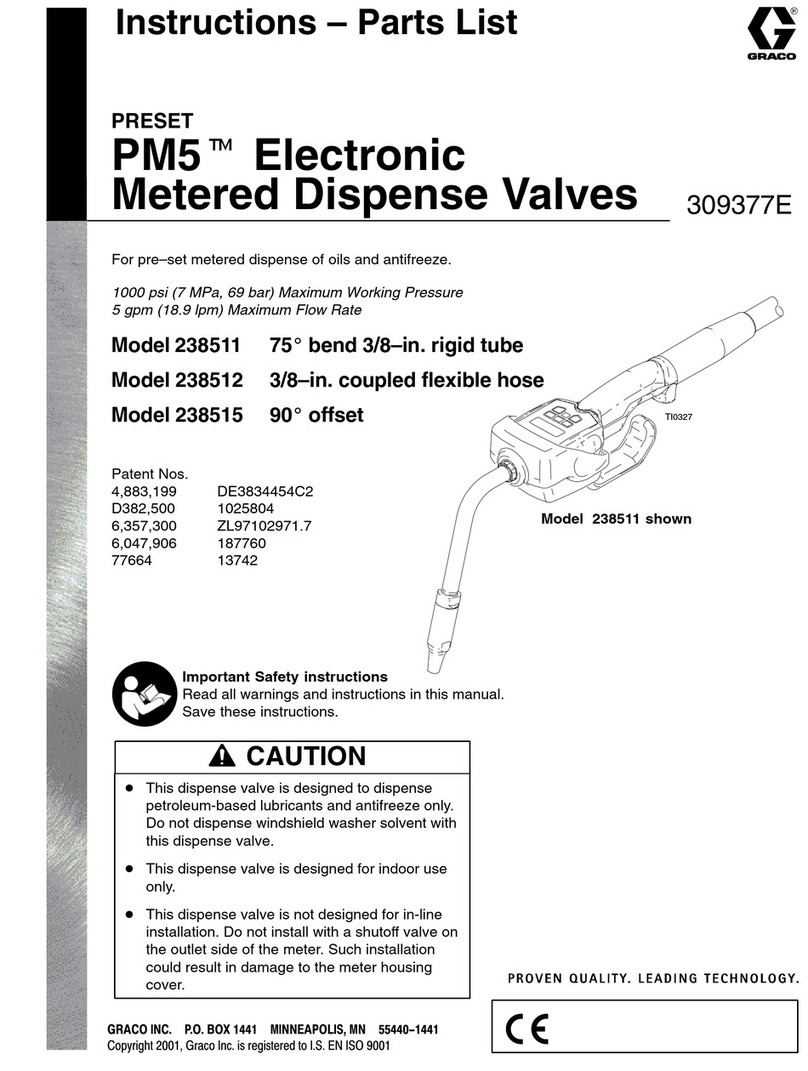

Graco PM5 238511 Datasheet

Graco

Graco Airgard 224-040 Operation manual

Graco

Graco 244912 Operation manual

Graco

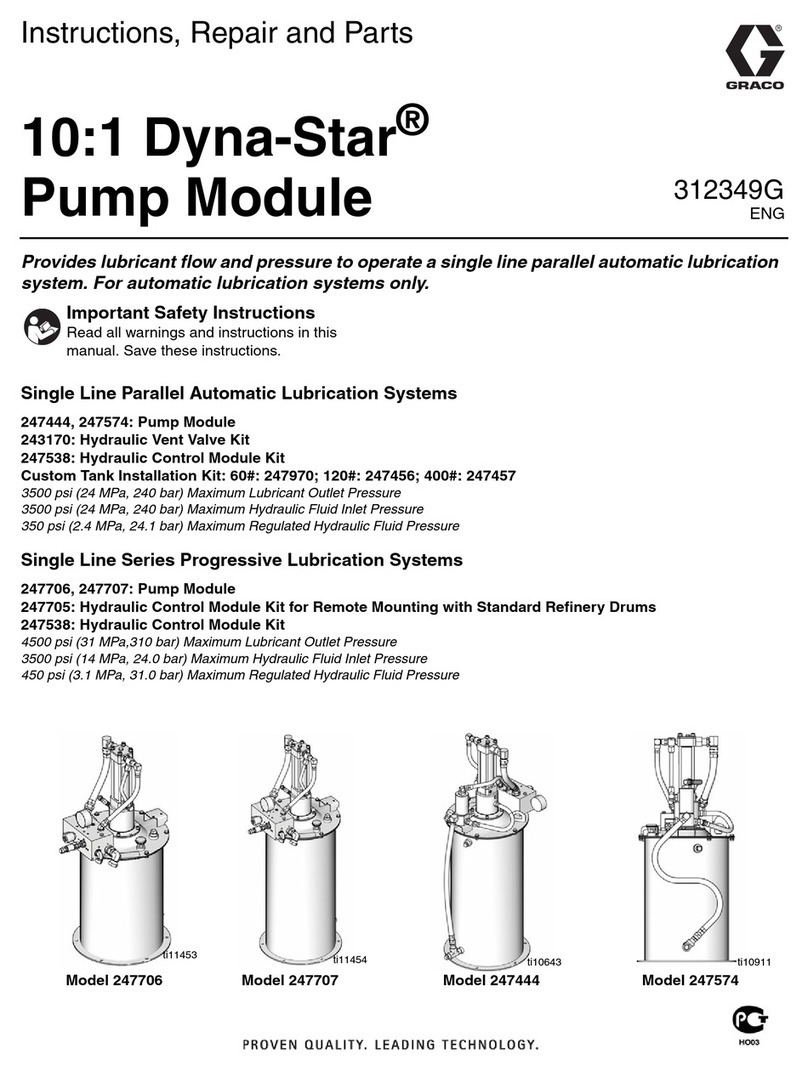

Graco 10:1 Dyna-Star 247444 Use and care manual

Graco

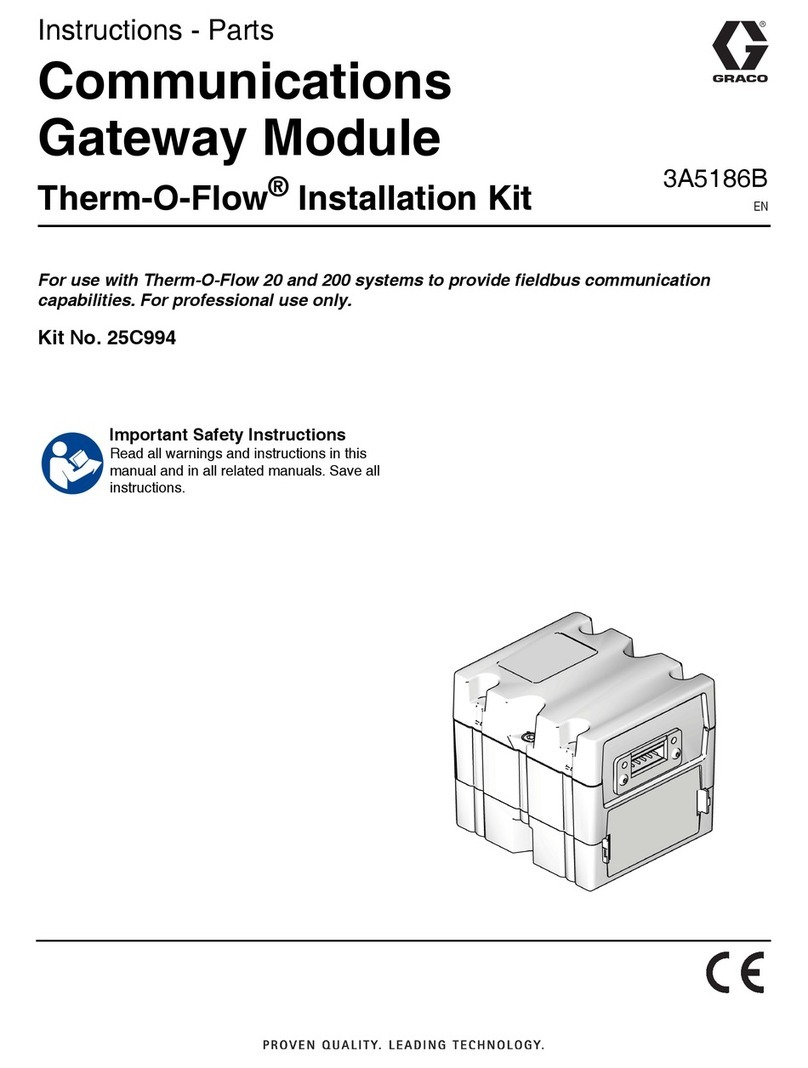

Graco Therm-O-Flow 25C994 User manual

Graco

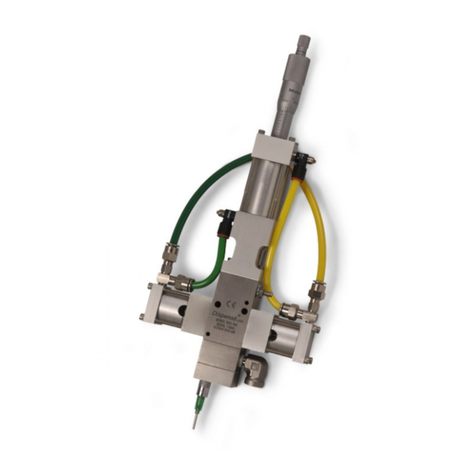

Graco Dispensit 1052 Troubleshooting guide

Graco

Graco Control Architecture Module Owner's manual

Graco

Graco Reactor 25D612 User manual

Graco

Graco 77X542 User manual

Graco

Graco 482 Series Operation manual

Graco

Graco PD44 Manual instruction

Popular Control Unit manuals by other brands

Festo

Festo Compact Performance CP-FB6-E Brief description

Elo TouchSystems

Elo TouchSystems DMS-SA19P-EXTME Quick installation guide

JS Automation

JS Automation MPC3034A user manual

JAUDT

JAUDT SW GII 6406 Series Translation of the original operating instructions

Spektrum

Spektrum Air Module System manual

BOC Edwards

BOC Edwards Q Series instruction manual

KHADAS

KHADAS BT Magic quick start

Etherma

Etherma eNEXHO-IL Assembly and operating instructions

PMFoundations

PMFoundations Attenuverter Assembly guide

GEA

GEA VARIVENT Operating instruction

Walther Systemtechnik

Walther Systemtechnik VMS-05 Assembly instructions

Altronix

Altronix LINQ8PD Installation and programming manual