Champ™ 600 Hot Melt Glue Gun

Glue Machinery Corporation™

4234 Boston St, Baltimore, Maryland 21224

Toll

F

ree

1-

888-202-2468 | Phone: 410-761-2727 | Fax: 410-761-5127 | Email: [email protected]

Temperature Adjustment

Manual thermostat adjustment instructions for Champ™600

1. Read and understand the manual prior to operating this equipment. Wear proper protective equipment while

operating or servicing this equipment. Only trained operators should be designated to make thermostat

adjustments to this equipment.

2. With the equipment hot, dispense all of the material from the tank; this is required to properly adjust.

Disconnect the equipment from power before servicing the thermostat. Locate the thermostat adjustment port;

this will be located on the top of the Champ™600 case.

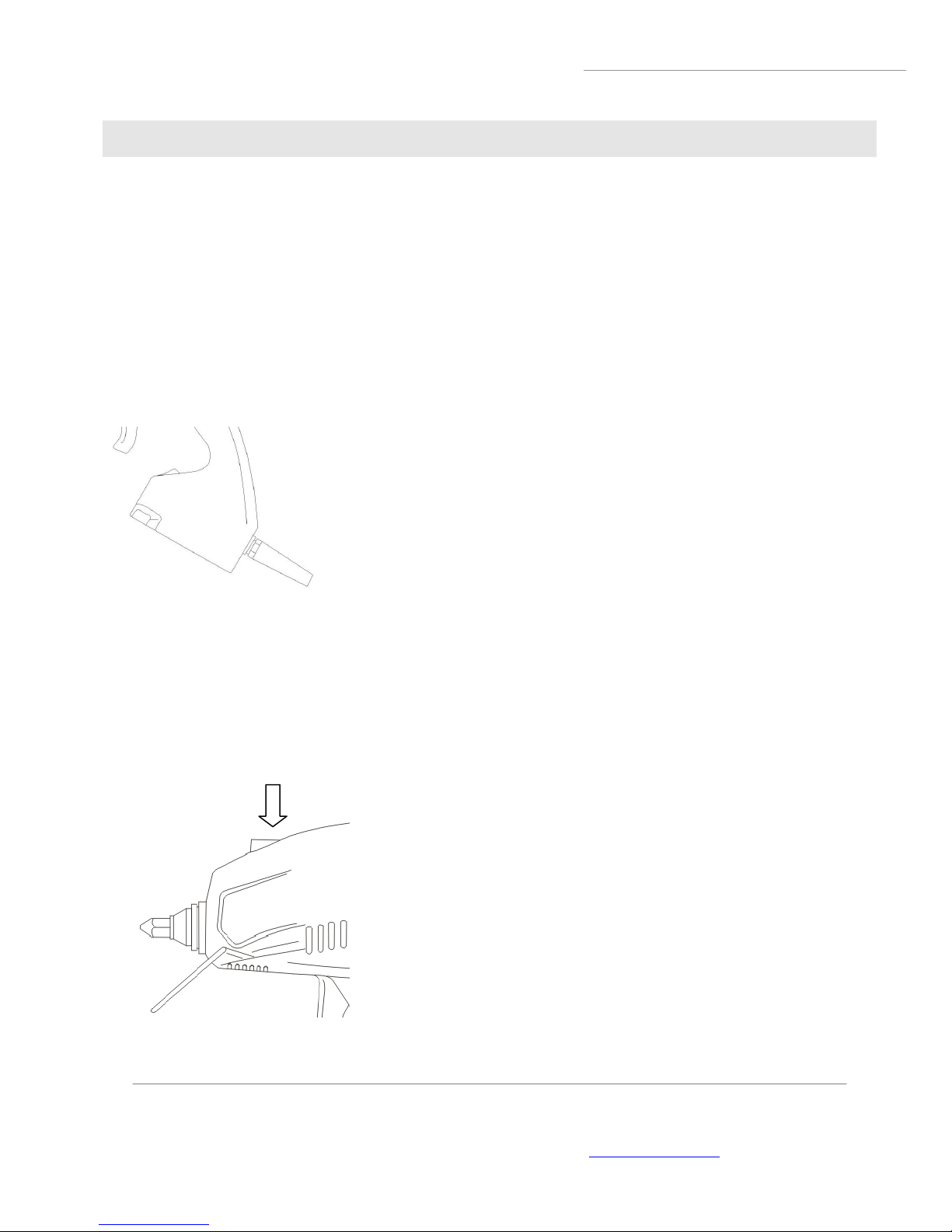

3. Using a 3/16” slotted screwdriver, insert the screwdriver into the port engaging the flats on the top of the

thermostat stud. Turn the thermostat stud counter clockwise until stop, reconnect the equipment to power and

turn on. Do not force the thermostat if there is any resistance.

If fumes come from the tank at any point during this procedure, turn the equipment off and turn the

thermostat adjustment stud counterclockwise until stop and restart the adjustment.

4. Let the equipment heat for 15 minutes while closely monitoring the internal tank temperature at the bottom

most location of the tank with a thermometer, bead probe sensor or laser temperature probe. Once this

temperature has stabilized this will be your factory set lowest temperature.

5. Power the equipment off and disconnect from the machine from the power source. Turn the thermostat

adjustment stud clockwise 1/2 turn then reconnect the equipment to power and turn on. Let the equipment heat

for 15 minutes while closely monitoring the internal tank temperature at the bottom most location of the tank with

a thermometer. Again, once this has stabilized this will be your average mid-range operating temperature.

5a. If higher tank operation temperatures are required, turn off the power and disconnect the equipment

from power. Turn the thermostat adjustment stud clockwise 1/4 turn then reconnect the equipment to

power and turn on. Let the equipment heat for 15 minutes while closely monitoring the internal tank

temperature at the bottom of the tank with a thermometer. Repeat this step until the desired higher

operating temperatures are achieved or the maximum clockwise stop is reached.

6. Once the desired operating temperature is achieved, fill the tank with approved hot melt adhesive and close

and secure the tank lid. Let the equipment heat for 20 minutes then slowly squeeze the trigger to properly prime

the piston pump while closely monitoring the dispensing material for degradation. If the material appears to be

darker than the hot melt prior to melting or it smokes when extruded please consider lowering the gun

temperature. Please note that all hot melts have a “Pot Life” and will start degrading with high temperature

exposure over time.

Basic Factory Settings:

Low temperature 295°F / Average mid-range temperature 360°F / Maximum temperature 435°F

Recommend thermometer: G71E47-001 Infrared Laser Thermometer

Estimated temperature change with 1/4 turns to the thermostat stud: 25°F

Average temperature fluctuations for mechanical thermostat 20°F +/-