CHAMP3TM HOT MELT GLUE GUN

PART #CHAMP3

Glue Machinery Corporation™

4234 Boston St, Baltimore, Maryland 21224

Toll Free 1-888-202-2468 | Phone: 410-761-2727 | Fax: 410-761-5127

Email: info@gluemachinery.com |www.GlueMachinery.com

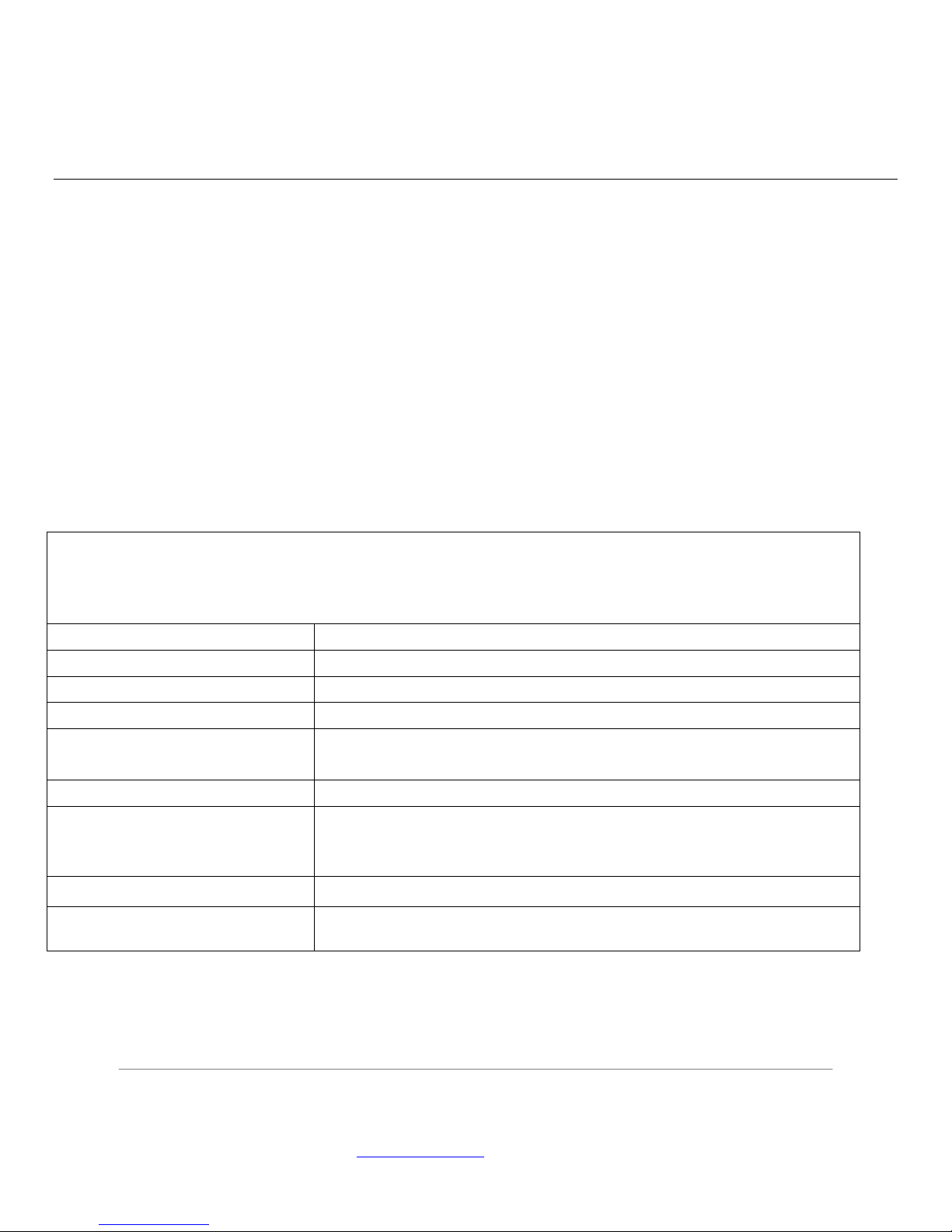

Requirements for Normal Operation

This industrial hot melt tool must only be used by persons trained and instructed in its proper use. User must be

familiar with all information provided in this manual.

Prior to each use, check the gun for visible damage and make sure that it is in perfect condition.

Immediately inform management of any detected problems with the Champ3TM.

Safety Instructions for the Use of the Hot-Melt Glue Gun Champ3TM

Fill melt tank to ¾ full with approved hot melt adhesive. Hot Melts are available in chips, pellets,

pillows or flyers. The bottom of the tank lid cap must not touch adhesive when inserted into tank

reservoir.

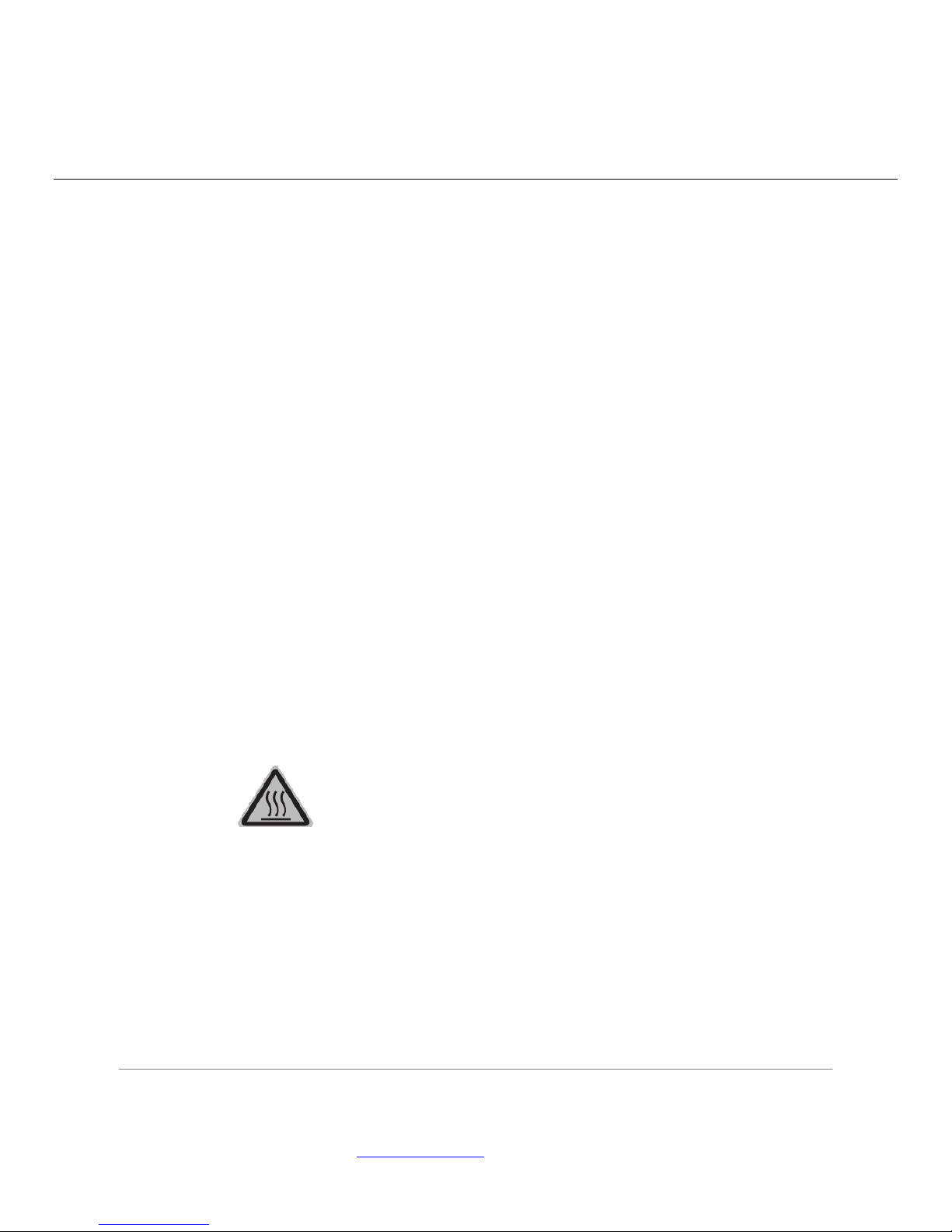

The nozzle and parts can heat up to 482°F / 250 °C Warning : Hot Surface

Never exceed working temperature of the hot melt.(Consult your adhesive manufacturer)

Overheating of adhesive may lead to degradation which could affect operator health and tool

performance.

Never operate glue gun without having installed a nozzle.

Do not direct glue nozzle towards people.

Prior to any nozzle replacement, unplug power cable.

When a nozzle is replaced, liquid glue may leak out. Warning: Risk of burning!

Never bring the hot nozzle in contact with the power cable.

Ensure sufficient ventilation when operating gun.

Do not inhale vapour escaping from the glue. Attention: inhaling this vapour may cause irritation of

the respiratory tract.

If your skin comes into contact with hot glue, cool it with cold water immediately.

Do not try to remove hot melt from the skin when molten. If necessary consult your doctor.

Never work without protective gloves, long sleeve shirt and glasses!

Never fill glue gun with any solvent or paraffin as this poses a risk of explosion.