Haklift Oy

Asessorinkatu 3-7

20780 Kaarina, Finland

Tel. +358 2 511 5511

www.haklift.com

Lifting Solutions Group

Axel Johnson International

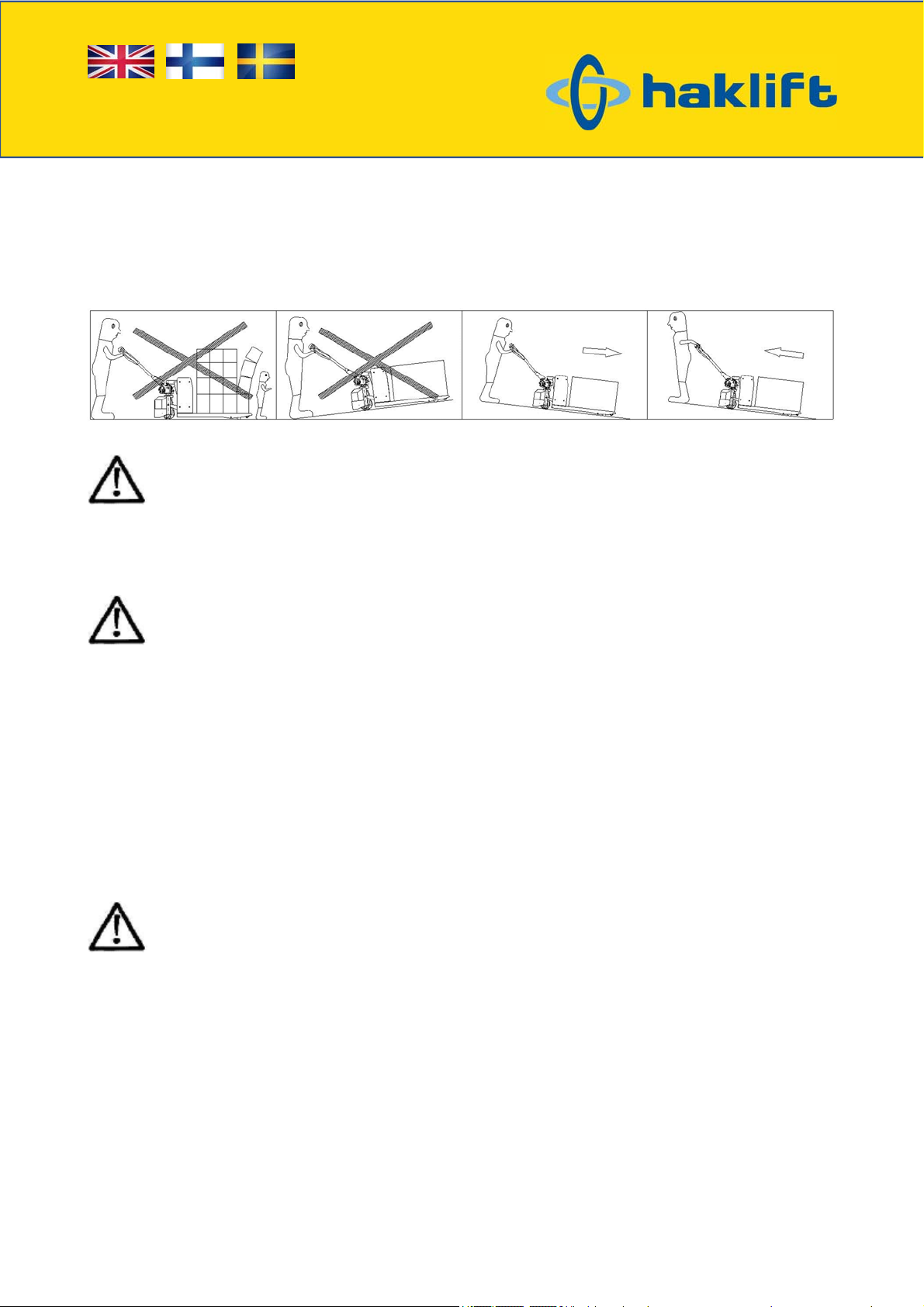

When there is a protruding object on the truck or around it, which may cause human injury

or forklift damage, one must be very careful.

It is strictly prohibited for people to stand/appear around the truck operation area, which

may cause human injury, for example, if the goods fall down.

Be careful!

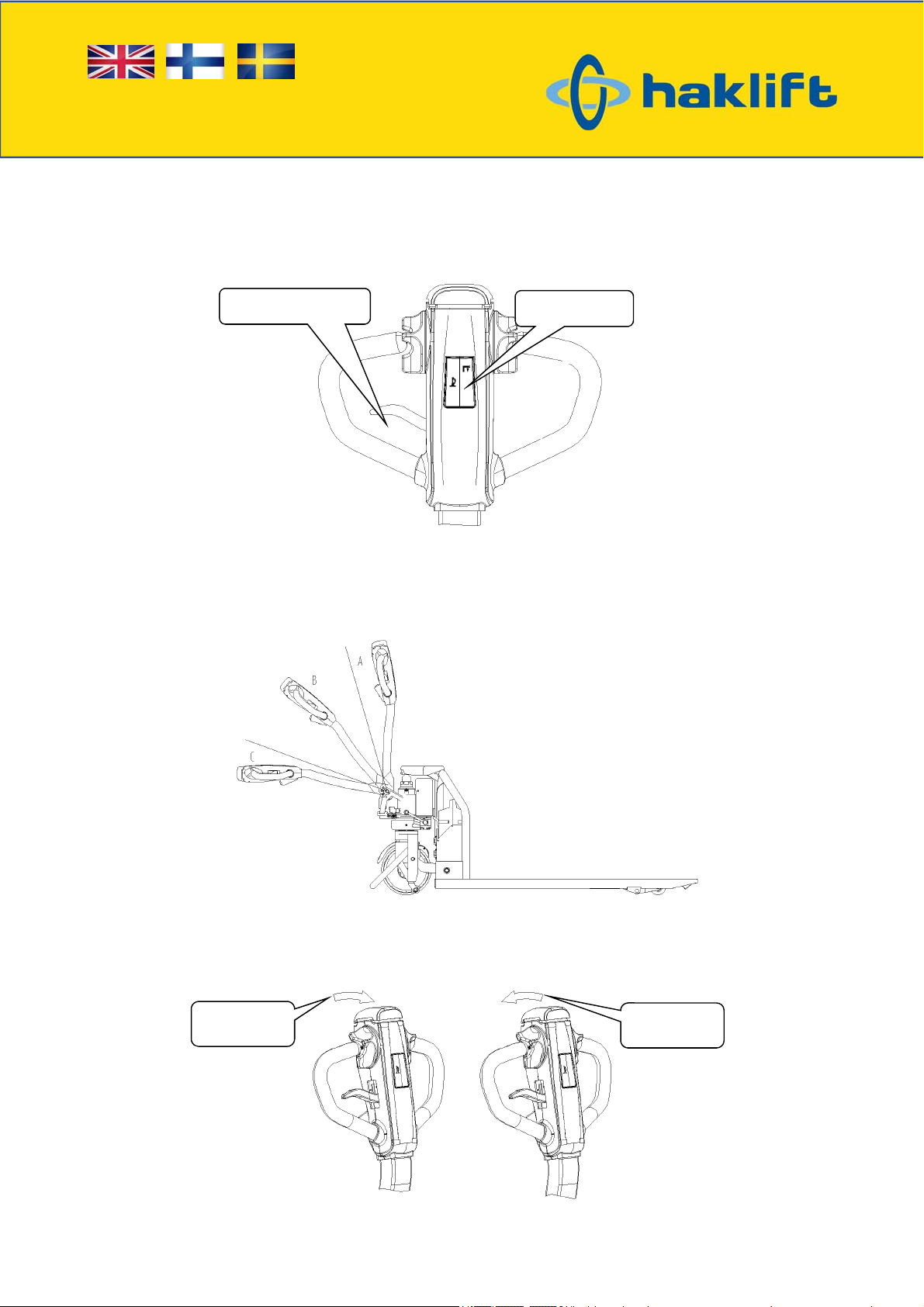

When handling goods on a slope, the operator must be very careful in operation. The

operator should operate in the upper part of the slope as shown in the figure above.

Warning!

When turning, high-speed operation should be avoided to prevent the truck from turning

upside down.

The goods should not be piled too high to avoid blocking the vision line.

Braking should be conducted slightly and very carefully to prevent the goods from sliding off

the tray, which may damage the goods.

It is not allowed for the truck to turn on a slope.

Before pushing the truck into an elevator, the operator must ensure that the elevator is able

to bear the total weight of the truck and the goods, the total weight of the operator and other

people in the elevator. When entering the elevator, make sure that the goods enter first and

then the operator. When the truck and goods enter or leave the elevator, other people must

not stay in the elevator.

Be careful!

The load weight should not exceed the truck’s rated load.

When piling goods, the goods must not be piled too high to avoid goods falling down or

truck turning over when handling.

It is strictly prohibited to use this truck to transport or lift human being.

No other people should stay around the truck operation area to avoid injuries and deaths

when the truck suddenly fails in operation.

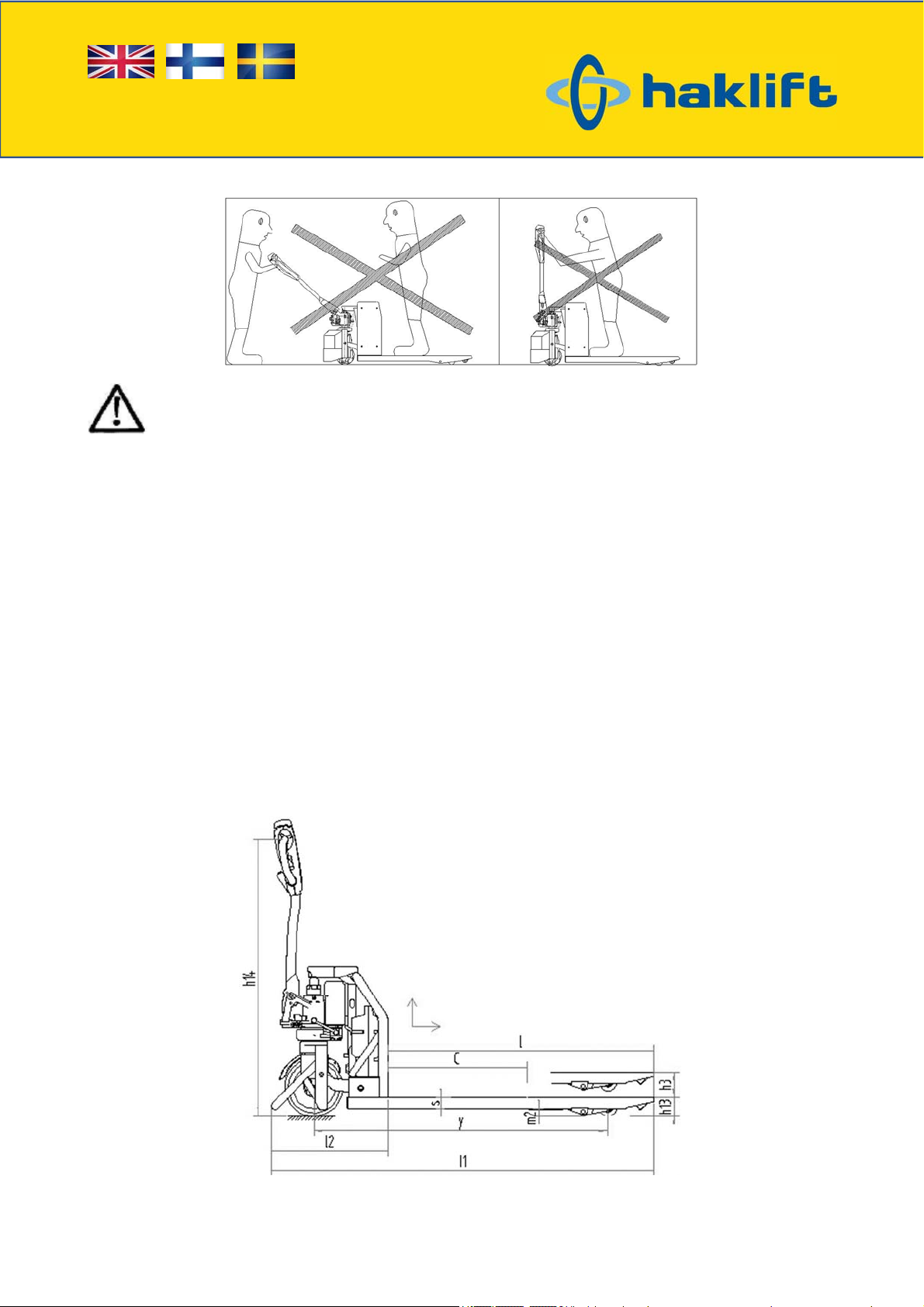

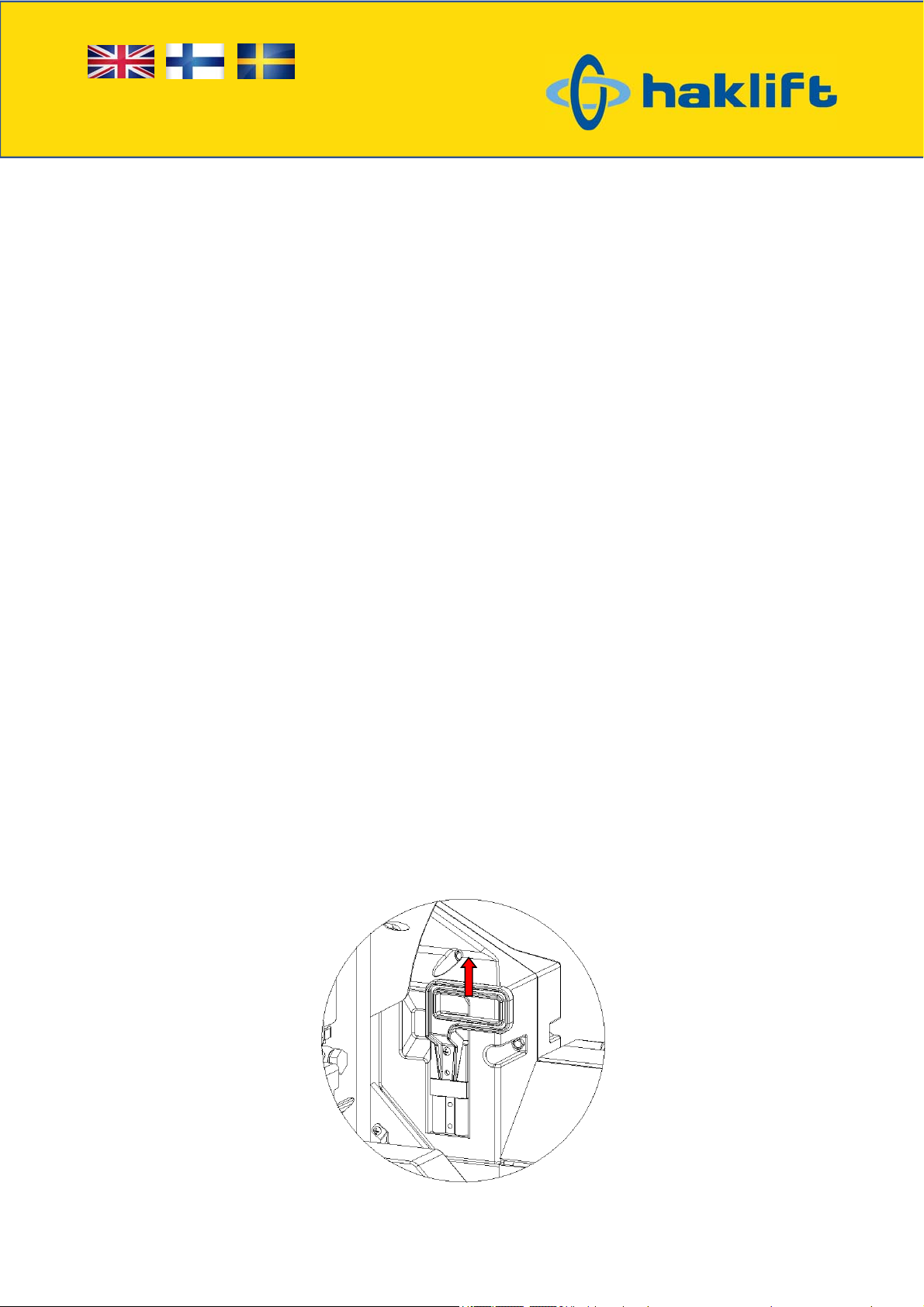

When operating the lever or pushing the truck, one must make sure the hand is put above

the lever.

It is not allowed to put any part of the body under the truck forks or the load.