Page 2

GENERAL INFORMATION

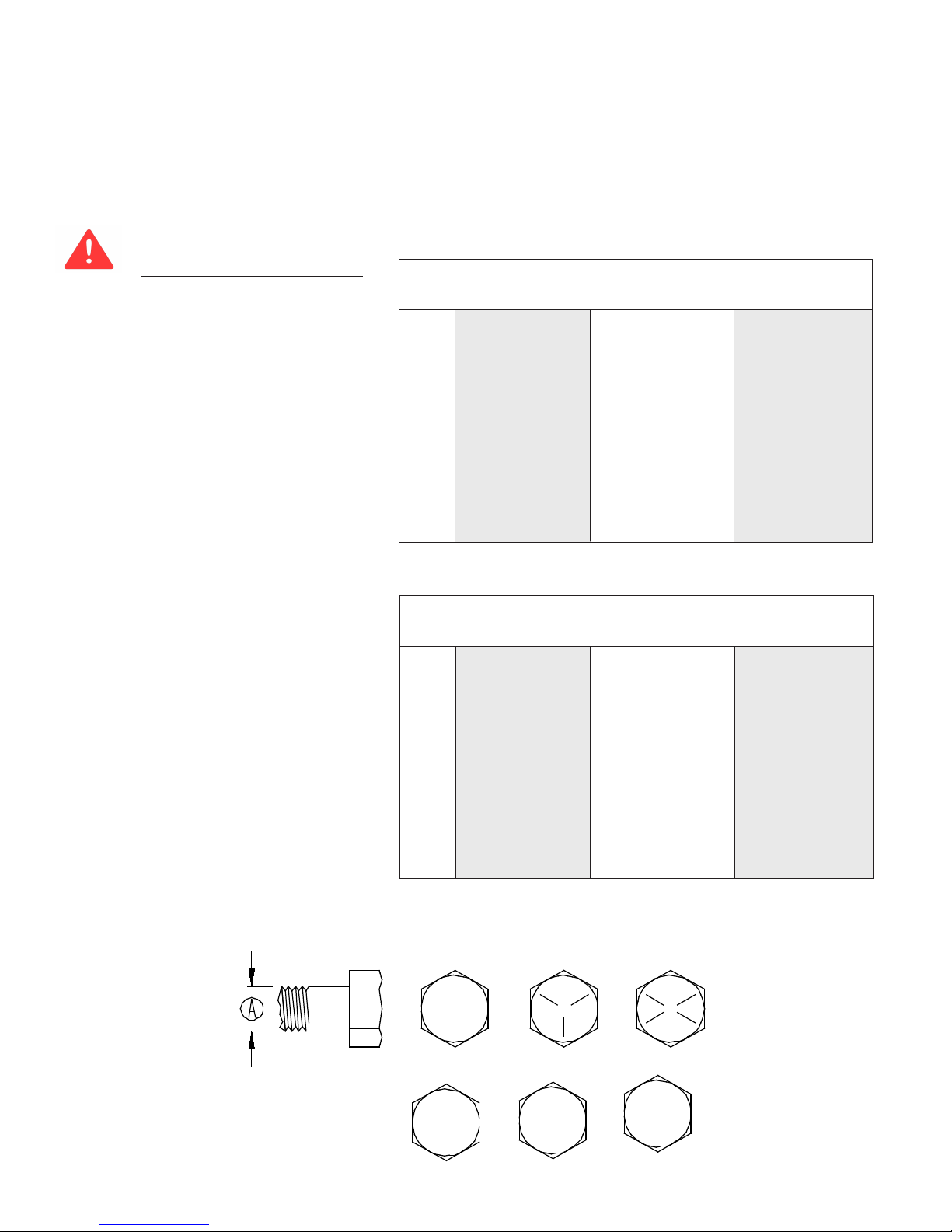

1. Unless otherwise specied, high-strength (grade5)

(3radial-lineheadmarkings)hexheadboltsareused

throughoutassemblyofthispieceofequipment.

2. Whenever terms “LEFT” and“RIGHT” areusedinthis

manualitmeansfromapositionbehindwagonboxand

facingforward.

3. When placing a parts order, refer to this manual for

properpartnumbersandplaceorderbyPART NO. and

DESCRIPTION.

4.Readassemblyinstructionscarefully.Study

assemblyproceduresandallillustrationsbeforeyoubegin

assembly.Notewhichpartsareusedineachstep.This

unitmustbeassembledinpropersequenceorcomplica-

tions will result.

WARNING: TO AVOID PERSONAL INJURY OR DEATH, OBSERVE FOLLOWING

INSTRUCTIONS:

Neveroverloadmixer.Ratingofgearorratingoftires,whicheverisless.

Ensurethatanybodypresentisclearbeforeapplyingpowertoanymachineryusedinconjunc-

tionwithwagonboxorwhenmovingbox.

Neverallowanyonein,near,oronmixingchamberduringmixing,transporting,orunloading

offeed.

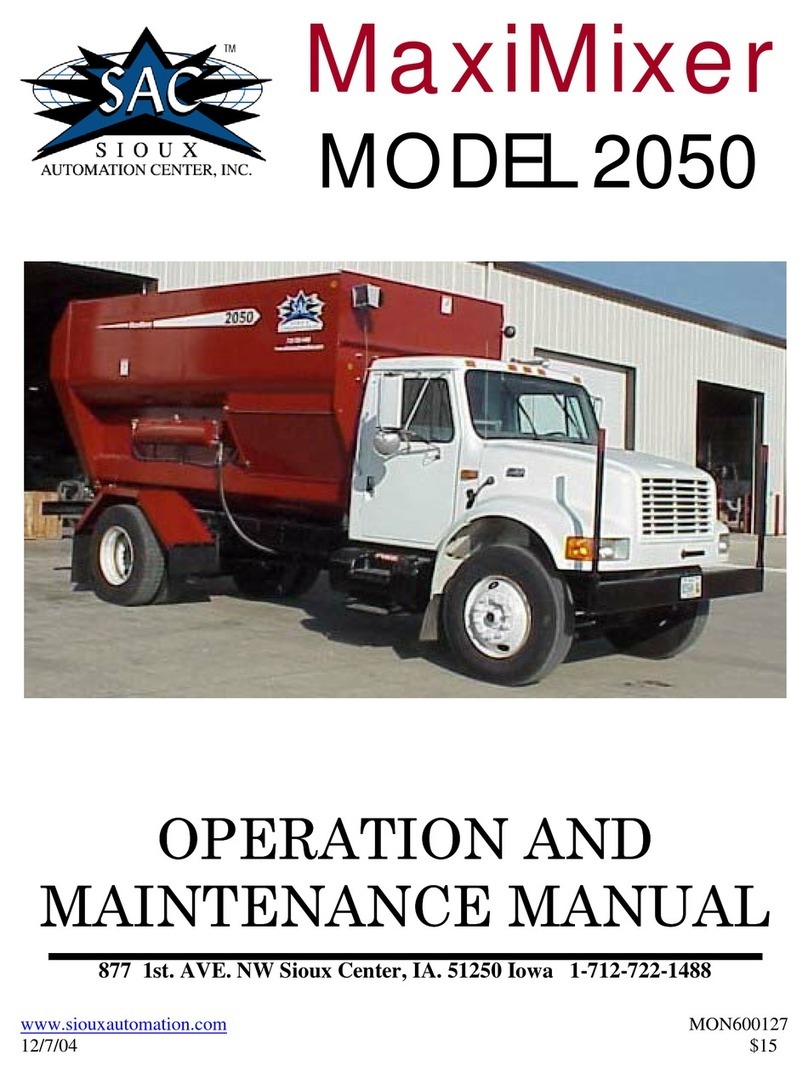

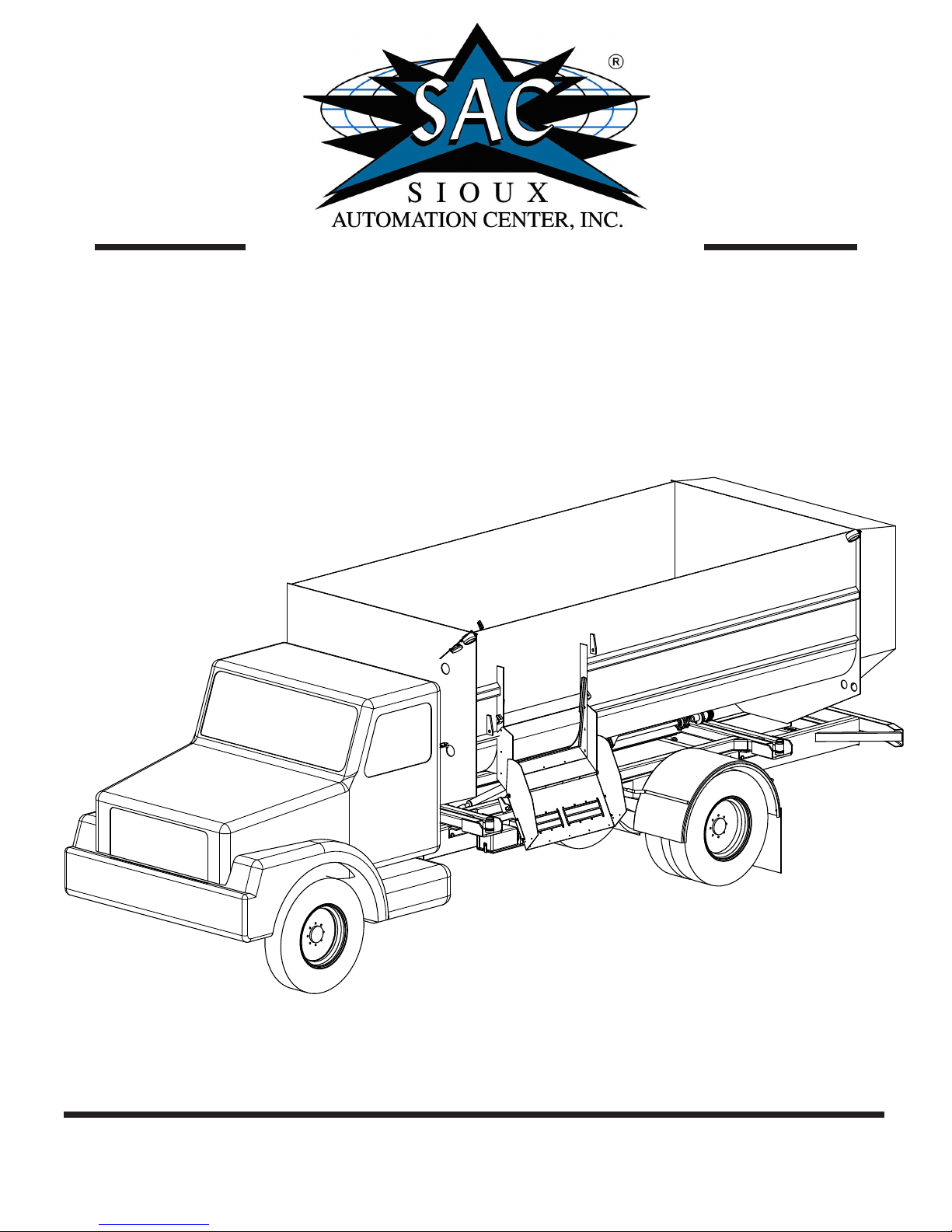

ThankyouforpurchasingaTurbo-MaxMixerTruck.Wefeelyouhavemadeawisechoiceandhopeyouarecompletelysatis-

edwithyournewpieceofequipment.YournewTurbo-MaxMixerTruckisadurable,efcientandeasytouseunit.Proper

careandusewillresultinmanyyearsofservice.

INTRODUCTION

Table of Contents

GeneralInformation ......................................................................................................................................................................... 2

Safety,SignalWords....................................................................................................................................................................... 3

EquipmentSafetyGuidelines........................................................................................................................................................... 4

LightingandMarking........................................................................................................................................................................ 4

SafetySignCare .............................................................................................................................................................................. 4

TireSafety ........................................................................................................................................................................................ 5

BeforeOperation.............................................................................................................................................................................. 5

During Operation.............................................................................................................................................................................5-7

Following Operation ......................................................................................................................................................................... 7

HighwayandTransportOperations.................................................................................................................................................7-8

PerformingMaintenance .................................................................................................................................................................. 8

BoltTorque ....................................................................................................................................................................................... 9

Mixer Setup ..................................................................................................................................................................................... 10

Mixer Operation............................................................................................................................................................................. 11-12

InspectionsandAdjustments .......................................................................................................................................................... 13

LubricationSchedule....................................................................................................................................................................... 14

Decal Location ................................................................................................................................................................................ 15

OilbathAssembly ............................................................................................................................................................................ 16

Reel&AugerAssembly................................................................................................................................................................... 17

FinalAssembly ..............................................................................................................................................................................18-19

Options............................................................................................................................................................................................ 20

DischargeBreakdown

SlideTray ................................................................................................................................................................................... 21

SlideTray(usedonserial#) ...................................................................................................................................................... 21

HydraulicBreakdown

ElectricSelectorValveforSlideTray .......................................................................................................................................... 22

SwitchboxAssembly

ToggleSwitchAssembly.............................................................................................................................................................. 23

JoystickAssembly ....................................................................................................................................................................... 23

DrivelineAssembly........................................................................................................................................................................24-25

GeneralSpecications .................................................................................................................................................................... 26

Warranty.......................................................................................................................................................................................... 27