www.gmetechnology.com 1

Introduction

Thank you for purchasing the HG139 HDTV (High Definition Television) Pattern Generator. It is an

easy-to-use handheld video pattern generator that generates a wide variety of test patterns for

comprehensive testing, calibration, and repair of HDTV, analog television monitors, and other video

equipments. The HG139 delivers the quality and functionality you would expect from an expensive

high end HDTV pattern generator at a very affordable price. With its easy to understand interface, the

HG139 is designed to meet the need of people from all levels ranging from novice to video

professionals.

The HG139’s clock frequency is 74.25MHz for HDTV modes. The test patterns are generated in real-

time by digital ICs and converted to analog output signal by three precision digital-to-analog

converters. The HG139 generates both a tri-level sync signal for HDTV monitors and a traditional bi-

level sync signal for NTSC monitor. The negative sync pulse amplitude is nominally -0.3 volts below

the blanking level and the positive sync pulse amplitude is nominally +0.3 volts above the blanking

level. Full-scale video/sync is generated in a 7:3 rate, compliant with SMPTE standards signals.

Item Checklist

9One HG139 HDTV pattern generator

9One protective rubber holster

9One 7.5V AC power adaptor

9Three BNC-to-RCA adaptors

9One User’s Manual

Features

♦Designed for testing, calibration, and service of High Definition TV and NTSC analog

television

♦4 selectable modes including 1080i, 720p, 480p, and NTSC

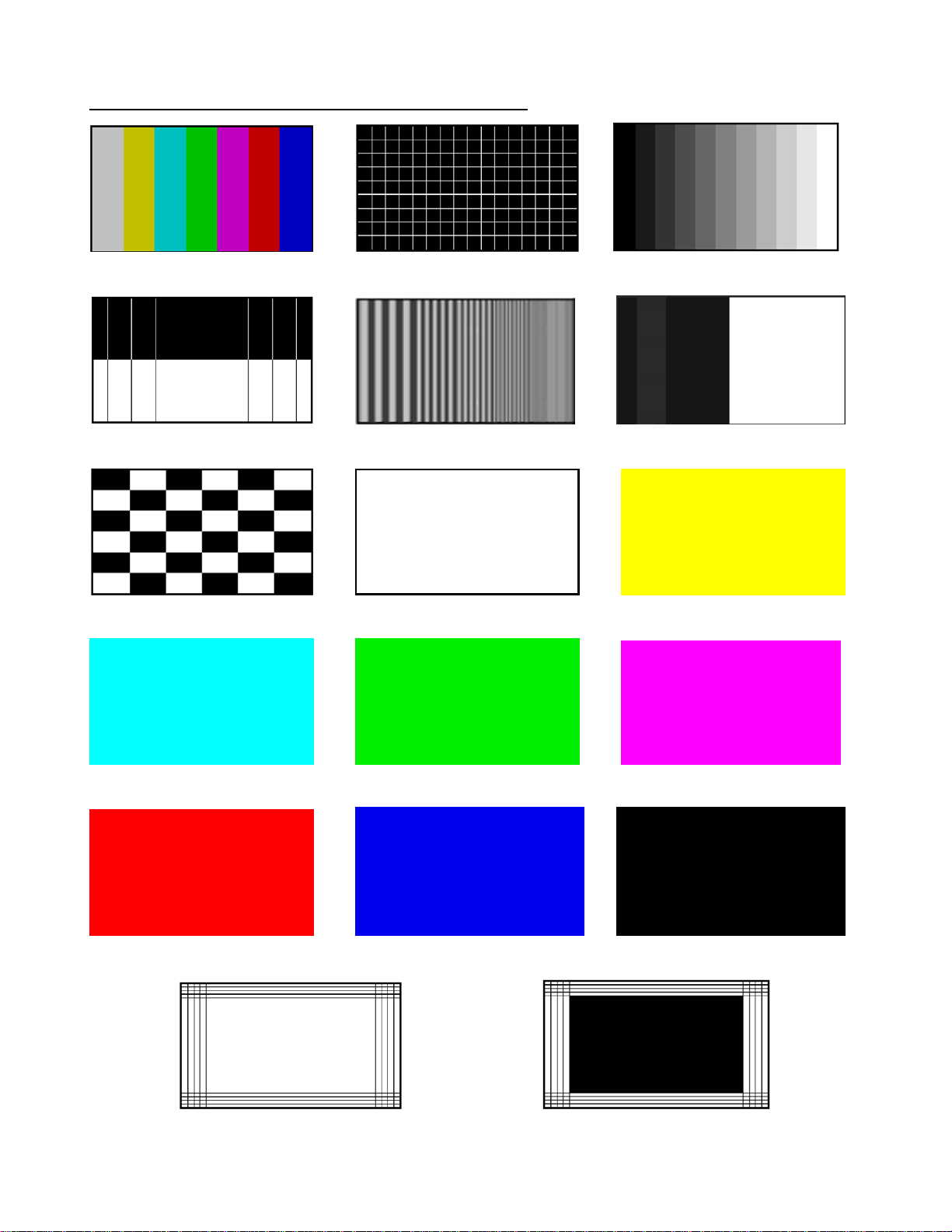

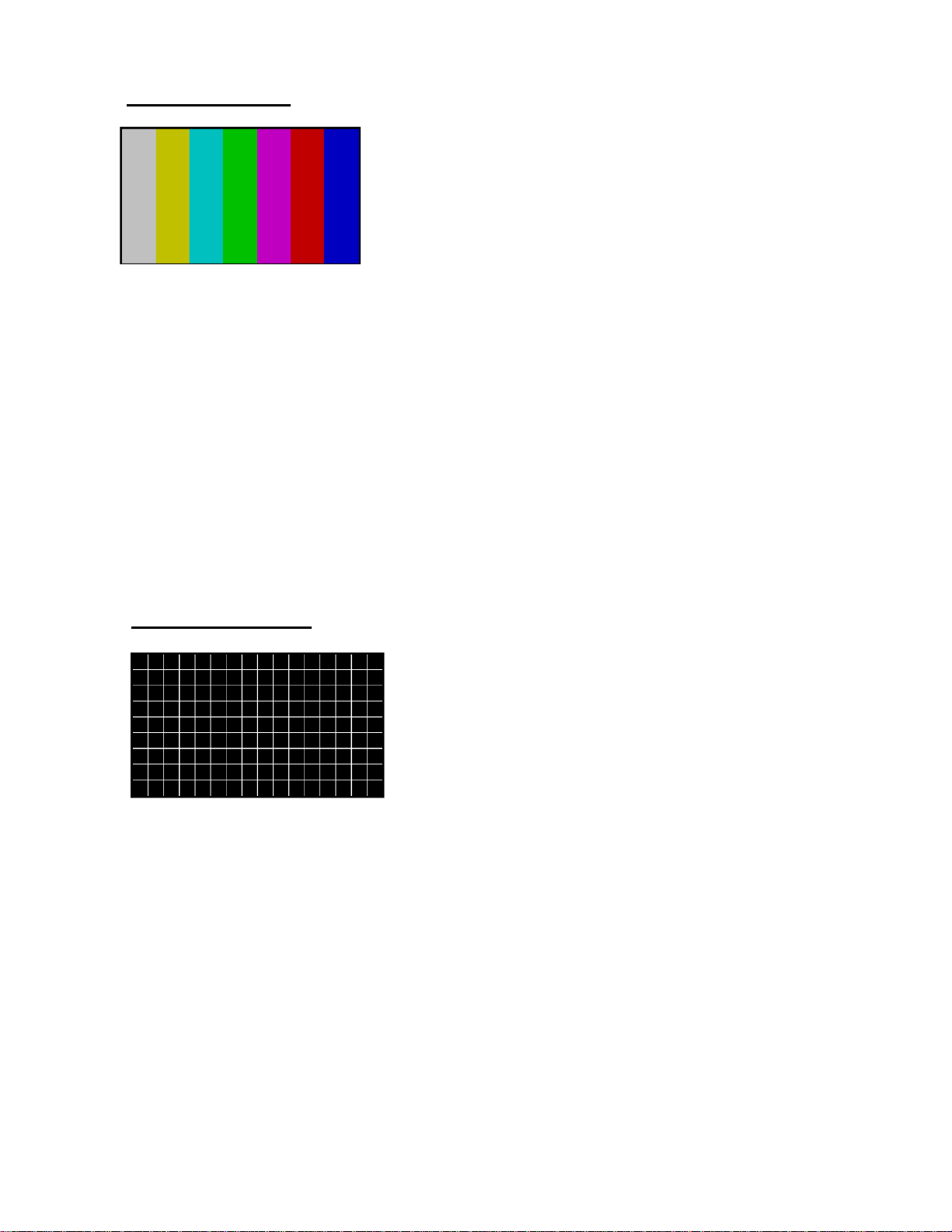

♦9 commonly used video test patterns including COLOR BARS, CROSS HATCH,

STAIRCASE, MULTIBURST, OVERSCAN-BOUNCE, PLUGE, NEEDLE, CHECKER, and

RASTER (choose from White, Yellow, Cyan, Green, Magenta, Red, Blue, and Black)

♦Single push button selectable patterns with hold down reverse

♦Precise 74.25 MHz HDTV clock frequency

♦Conform with SMPTE and NTSC industrial video standards

♦AC adaptor power source or standard 9v battery operation

♦Low battery indicator

♦Handheld enclosure with protective rubber boot

♦Ideal for on-the-bench and in-the-field testing

♦Easy to use, lightweight, portable, and affordable