GMP EXCELAM-1100SWING User manual

User Manual for EXCELAM-1100SWING

EXCELAM-1670SWING

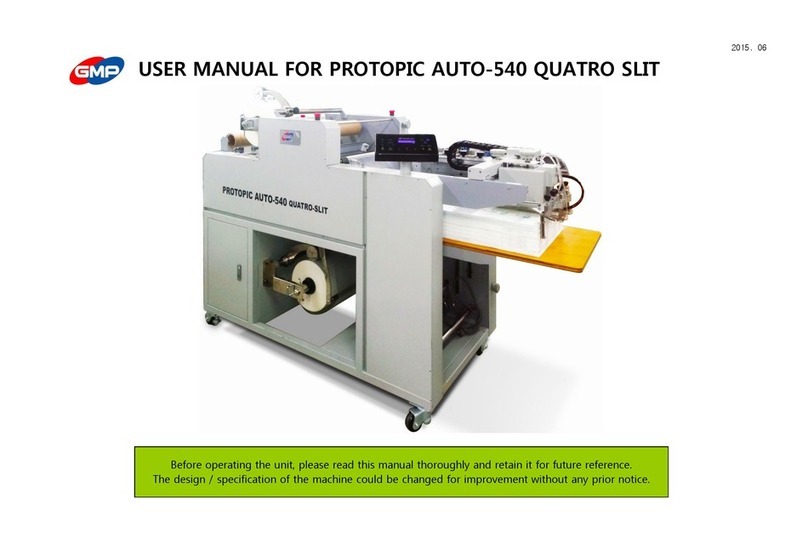

Before operating the unit, please read this manual thoroughly and retain it for future reference.

※ The design / specification of the machine could be changed for improvement without any prior notice.

INDEX

◐ SAFETY PRECAUTION ◐ HOW TO LAMINATE

Important Safety Instruction 3 page Hot Laminating 23 page

Safety device 7 page ULTRA-THIN OVERLAY COATING 27 page

Warning Sticker 8 page (MICRONEX FILM LAMINATING)

Cold Laminating 30 page

◐ INSTALLATION

Mounting 32 page

Packing Contents 10 page

Part name 11 page ◐ LAMINATION GUIDE 33 page

Carriage and Installation 14 page

◐ PRODUCT MAINTENANCE 35 page

◐ USAGE OF CONTROL PANEL

Control Panel 16 page ◐ TROUBLE SHOOTING 36 page

Function Button 17 page

◐ PRODUCT SPECIFICATION 38 page

◐ USAGE OF MAIN DEVICE 20 page

◐ GMP SUBSIDIARIES 39 page

IMPORTANT SAFETY INSTRUCTION

It is for the purpose of user's safety and prevention of the property loss.

Read thoroughly the following contents and use rightly according to the manual.

Safety instruction is classified as "Warning" and "Caution", the meaning is as follows;

Warning :If you ignore this symbol, you can suffer serious injury and sudden to death.

Caution :If you ignore this symbol, you can receive a severe wound and property loss.

This symbol means a prohibited action.

If you ignore a prohibited action, you can suffer a personal injury and damage by the result of machinery.

This symbol means a required action. If you don't follow this action, Your safety is not guaranteed.

Required action will be included in this symbol.

Reference : The sign above refers the contents for user's safety and prevention of Property loss.

3/39

IMPORTANT SAFETY INSTRUCTION

Connect or dissemble the power plug with a wet hand. It make a electric shock

Do not use more than one outlet with other products. The overheating of the outlet can be a main reason of a fire flame.

Do not use without a specified power supply and voltage. It makes a fire or an electric shock

Inset the power plug inside firmly. The overheating of an outlet can make a fire flame,

a malfunction and losing electricity make an electric shock.

Grounding is needed for your safety.

A malfunction and losing electricity make an electric shock.

Do not damage or transform a power cord and a plug. It is a main cause of a fire or an electric shock.

Do not curve the power cord or pull, press with a heavy weighted materials.

The power cord damage can make a fire or an electric shock..

POWER

GROUNDING

WARNING

4/39

IMPORTANT SAFETY INSTRUCTION

Do not use materials near the heating place or flammable materials. It makes a fire flame.

Do not place nearby a place just like a dark place or slope

Do not use more than one outlet with other products. The overheating of the outlet can be a main reason of a fire flame

Do not dissemble, make repairs, convert. It makes a fire flame or an electric shock Contact with the purchase place about

the checks inside the laminator or making repairs.

Please, avoid wearing loose outfits such as a necktie, a necklace or shirts with a long lace.

Such an outfit might get stuck into the roller or the rotating part and you might be exposed to fatal injury.

Do not remodel the safety switch artificially. Refer servicing to qualified service personnel.

Do not put a kind of a water like liquid on the machine, It makes an electric shock or malfunction.

Do not use a flammable spray or flammable materials inside or outside the machine. It makes a fire flame

Keep away the machine from children. You can get burned or suffer an electric shock

When you move this product, Switch off and segregate the plug from the outlet. If the cord is damaged, it

make a fire or an electric shock.

If you left the machine for a long time, necessarily switch off and then segregate the plug from the outlet.

Installation & Usage

CAUTION

POWER

5/39

IMPORTANT SAFETY INSTRUCTION

Take care of yourself from wound by cutting knife.

This product is too heavy so, necessarily a lot of people should carry the product when unpacking or carrying,

if you don't , it makes a product damage or personal injury

Be careful not to allow a part of your body or other alien substance wound into the gear or the chain.

That's the reason for injury and malfunction of the machine.

The laminating roller is very hot. If your body contacts it, you might suffer a burn.

Please avoid installing near the following places;

- Gas stove, Ventilator or Air conditioner due the higher temperature or higher humidity

- Do not place any materials on the laminator as they could catch a fire

- Avoid the direct sunlight for the installing the machine

- Make sure no vibration and dusts are found in the place during the installation.

- Avoid the dark and slope place for installation

Don't place an object on the product. The upper part of the main body is hot, objects on the surface will be deformed

or the equipment will malfunction.

During operation, the upper part of the machine and the film right after laminating are very hot. You might suffer a burn injury.

Do not use except laminating. It is a main reason of an accident or malfunction

Please arrange the surrounding during laminating.

Installation & Usage

6/39

SAFETY DEVICE

☞ Emergency Switch

This device is stopping the system operating and running motor of roller, at emergency.

when this switch is pressed, the system does not operate.

☞ Location of Emergency Switch

☞ Emergency stop and release

Press the emergency switch(red button) will stop the motor.

Release of emergency switch can be made when you

turn right the red emergency switch

Emergency switch

Housing

Emergency Switch

7/39

WARNING STICKER

In order to avoid an unexpected damage & to keep the operators' safety, the Warning Stickers are on the machine.

☞ Roller ☞ Extremely high Temperature

Do not insert the Hand or body to the rollers Be cautious not to touch the surface

This would be a cause of damage by high temp. & pressure of rollers.

☞ Blade ☞ Chain

Keep away from the blade Do not insert the hand or body to the Chain.

This would be a cause of personal injury This would be a cause of damage of

severance of body by a chain.

☞ Electricity

High voltage of Electricity flows inside

Be cautious of electric shock, while operation

You may get injury or death by electric shock

Warning Sticker

8/39

WARNING STICKER

Location of Warning Sticker

9/39

PACKING CONTENTS

Packing contents

LAMINATOR

FUSE 3A 2EA

FUSE 6A 2EA

(UL 5A 4EA)

2.5mm T wrench 1EA

3mm L wrench 1EA

5mm L wrench 2EA

User Manual

10/39

PART NAME

1. Rewinder tension Control handle 4. Roll film 7. Control panel

2. Laminating roller 5. Caster 8. Roller Pressure Control handle

3. Front Table 6. Rewinder 9. Stand

Part Name

2

4

6

7

9

8

5

3

1

11/39

PART NAME

Main Device

Film tension handle

Roller safety cover

Power switch

Film shaft holding pin

Emergency switch

Side slitter

Film trimmer

Rewinder tension control

Pressure plate

Idle roller

Film core

Foot switch

12/39

PART NAME

Emergency switch

When pressing in emergent situation, motor stops.

Film shaft Device for installing laminating film rolls

Film shaft holding pin This is not to let film shaft move needlessly

Laminating roller

Heating & pressing roller

Idle roller This is to make being-laminated film flat for good lamination result.

Pull roller To provide final direct effect to flat result of laminated film

Film tension Control handle To adjust film tension.

Rewinder To rewind release liner etc.

Rewinder tension Control handle To adjust rewinder tension

Control panel To set condition for lamination job & operate machine

Power switch

To supply electricity power to machine

Side slitter Slitting the width of laminating film

Film trimmer To cut off laminated output

Pressure plate To get paper flat when feeding.

Roller pressure adjustment handle

To adjust pressure of laminating roller

Roll film Laminating roll film

Film core To fix roll film stably.

Foot switch To rotate laminating roller

Casters To move machine conveniently

Main Device Explanation

13/39

CARRIAGE AND INSTALLATION

Product Carriage

This product is too easy to carry mainly due to the moving wheels.

At transportation, "Moving wheel "works after pushing the moving wheel locker's direction "OFF" and then push the laminator

The product is too heavy to carry, therefore more than two persons should carry the laminator.

If you carry this product, necessarily move it with a forklift truck

After a product installation, Push "the moving wheel locker's direction "On".

it prevent the movement of a product due to the wheel locking

Caution : This product is too heavy to carry, therefore more than 3 persons carry this product.

If you don't, it is a main reason of a product breakage and personal injury

Caution : On carrying a product, segregate the power plug from the outlet. It is a main reason of an electric shock.

Usage of Caster

In the same place, you can move the laminator using the moving wheels, and install the machine in a short distance.

When you move the laminator, unlock the fixing device attached on the moving wheels.

The locking of wheels or unlocking of the fixing device is as follows ;

When you push the "Lock(ON)" lever, the wheels are locked, otherwise unlocked.

When push Unlock(OFF) lever, the wheels are unlocked

After the movement of laminator, necessarily fix the wheels.

Carriage and Installation

잠김(ON) 풀림(OFF)

UNLOCK(OFF)

LOCK(ON)

14/39

CARRIAGE AND INSTALLATION

잠김(ON) 풀림(OFF)

Caution : Necessarily grounding is needed for your safety

At the case of malfunction and electric leakage can make an electric shock.

Caution : Do not use more than one outlet with other products.

The overheating of the outlet can be a main reason of a fire flam.

Caution : Do not use without a specified power supply and voltage. It makes a fire or an electric shock.

Caution : Inset the power plug inside firmly. The overheating of an outlet can make a fire flame,

Caution : The socket-outlet shall be installed near the equipment and shall be easily accessible.

Carriage and Installation

Connecting Power :

Power supply should be used AC 220V/20A above. Necessarily Grounding is needed for your safety.

Grounding

잠김(ON) 풀림(OFF)

Product Carriage and Installation :

When you carry this product, more than 3persons necessarily carry safety.

Product placing should be installed at the hard and balanced floor.

15/39

USAGE OF CONTROL PANEL

1. TEMP.DISPLAY WINDOW

Displays the present temperature or setting temperature of roller

Temperature setting range is from Min. "0℃" to Max."160℃"

Note : Refer to function button guide to check present temperature or set up the temperature.

This product has function of self-diagnosis for troubles.

If a heater temp. is not adjusted and heater is overshooting, as the left picture,

"OH" is displayed. Then, power off the machine and ask to supplier.

2. Speed Display Window

Displays the roller rotating speed, changing width is "1~9".

Note : Roller rotating speed can be made by "Speed button".

3. Job Condition Saving No.

can memorize the different working condition from "1" to "9", the displayed number.

Note : Working condition change can be adjusted by "Job button".

4. Job Display

"WAIT" : "WAIT" means that the roller temp. is not enough to laminate

compared to the setting temp.

At the condition of "WAIT", the laminating status is not good.

"READY" : READY means that heat plate temperature reached to a setting temp.

Start laminating when the "READY" displays.

Control Panel

1

4

2

3

EXCELAM-1670SWING

16/39

USAGE OF CONTROL PANEL

1 - MEMORY

is for memorizing of working condition.

2 - JOB

is for working condition memorized from JOB1 to JOB9.

☞ Saving working condition

1) By using Job button, select the number to memorize. (Selected number displays on window)

2) Set the roller temp. and speed by using temp./speed button.

3) If you press the "MEMORY", setting value automatically is memorized.

☞ JOB Function?

is memorizing a reiterating working condition and preventing to remove for the repeating setting

working condition by button setting. From Job1~9, 9 working condition can be memorized.

Note : When you change the temperature or speed, the changed number and current

job number flickers for 2senconds. The flickering alarms that the setting value

is correct and asks that saving the changed contents to memorize at the job condition.

3 - MEASURE

When you press the "MEAS", beeps and roller temp. flickers on the "Temp. Display Window"

It is for the purpose of separating setting temp.

if you take off the button, again setting temp. displays.

4 - COOLING

is for cooling motor running. When you press the "COOLING" button for one time,

cooling motor runs and again press the button, the motor stops.

Note : Bad laminating condition change can be adjusted by "Cooling button".

Start when the machine can not cool down naturally by itself

Function Button

2

3

1

4

EXCELAM-1670SWING

17/39

USAGE OF CONTROL PANEL

5 - TOP/BOTTOM TEMPERATURE

To set up the Roller Temp. Temp. Setting Range is "0 ~ 160"℃ .

First press the button one time, temperature goes up(down) by "1℃", continuous pressing

can make that for the first 2second, goes up 1℃ by 0.5sencond, after then goes up 10℃rapidly.

6 - SPEED

To set up the laminating speed. Speed setting range is "1 ~ 9".

☞ Roller Rotating Speed Change

1) When roller rotates : For the time of roller rotating, if you change the speed,

rollers rotate at the changed speed.

2) When roller stops : In the case of roller stopping, if you change the speed,

roller does not change and only the number of speed window changes.

If you want to rotate the roller, press run button.

7 - RUN

is for roller rotation. When you press "RUN" button, stopped rollers rotates at the setting speed.

8 - STOP

is for roller rotation stop. When you press "STOP" button, rotating rollers stop.

9 - REVERSE

is for roller reverse-rotation. During "REVERSE" button pressed, the roller reverse-rotates

and the number of speed flickers and "beeps". This sound happens when the roller reverse-rotates,

at the same time of reverse-rotation stop the roller stops

Note : When the roller is reverse, the speed will be automatically change to “Speed 1”

6

7

8

9

5

EXCELAM-1670SWING

18/39

USAGE OF CONTROL PANEL

10 - STAND-BY

Is for stand-By the machine.

☞ STAND-BY MODE ?

When you leaves the machine for long time, the roller temp. can be controlled below 80℃

or cut off the power of machine.

1) Setting by Users : For short time, if you does not operate the machine, it can be used.

At the normal condition if you press the "STAND-BY" button, the setting temp.

can be changed to 80℃ automatically. (The operating condition stops)

2) Automatic setting by microprocessor : If you leave the machine for 3hours,

micro-processor installed in machine controls the roller temp. below 80℃.

(If the setting temp is below 80℃, it is controlled at the 0℃)

At this time, stand-by display lamp is on, Job display or Heater display window is cleared.

and then one and half hour passed, Stand-by Mode flickers and Power of heater is cut off.

Note : At the above two condition, release of standby mode is available by pressing

"STAND-BY" button again. If the saving mode is released, all conditions come back

to the previous status of stand-by mode.

EXCELAM-1670SWING

Before Stand by Mode

STAND-BY MODE

Setting(Safety) Mode

Release STAND-BY

10

19/39

USAGE OF MAIN DEVICE

☞ POWER SWITCH

is for supplying or cutting off the power, circuit breaker installed, at the time of overloading of machine,

current overflow, automatically cut off the power.

When the switch direction is "I", the power is on, otherwise the power is off.

Remark : If found wrong operating continuously please contact to your agent or distributor.

☞ FRONT SAFETY LEVER

Front Safety Lever is designed for user's safety and prevention to breakdown.

When install Front Plate, pull Front Safety lever.

When install Front Plate, Front Safety Lever will be restored.

Remark : If Front Safety Lever does not lock up, Roller will not run.

☞ PRESSURE PLATE

Pressure Plate is a function that smooth out a sheet on the plate.

When install Pressure Plate, please make sure that pull Levers at both edges.

When install Pressure Plate, Front Safety Lever will be restored.

☞ FILM TENSION CONTROL HANDLE

Film Tension Control Handle is a function that adjust tensile of film.

About film tension, adjust as much as a sheet can be spreaded passing between the rollers.

When turn the Film Tension Control handle to the right, film tension increases and turn to the left,

it decreases.

20/39

This manual suits for next models

1

Table of contents

Other GMP Laminator manuals

GMP

GMP QTOPIC-380 User manual

GMP

GMP GraphicMaster 1600HR User manual

GMP

GMP EXCELMASTER-1600 User manual

GMP

GMP PROTOPIC III-540 User manual

GMP

GMP SURELAM-PRO540HR User manual

GMP

GMP ELECTRO ULTRA LAMITRIM-1800 User manual

GMP

GMP RTR-380COMBI User manual

GMP

GMP PROTOPIC AUTO-540 HS User manual

GMP

GMP PROTOPIC-540 QUATRO SLIT User manual

GMP

GMP PROTOPIC AUTO-540 HS User manual