GMP PROTOPIC AUTO-540 HS User manual

2015. 07. 29

USER MANUAL FOR PROTOPIC AUTO-540 HS

Before operating the unit, please read this manual thoroughly and retain it for future reference.

The design / specification of the machine could be changed for improvement without any prior notice.

INDEX

◐ SAFETY ◐ HOW TO LAMINATE 42 page

Important Safety Instruction 3page

Safety Device 6page ◐ MAINTENANCE 48 page

Warning Stickers 8page

◐ TROUBLESHOOTING 49 page

◐ INSTALLATION

Packing Contents 10 page ◐ SPECIFICATION 54 page

Main Devices 11 page

Move & Installation 14 page ◐ DIGITAL SLEEKING SOLUTION

Introduction of DIGITAL SLEEKING SOLUTION 55 page

◐ HOW TO USE CONTROL PANEL

GLOSS & MATT SLEEKING

56 page

Details for Display 22 page HOLOGRAM SLEEKING 60 page

Control Panel 25 page METALLIC SLEEKING 64 page

Messages 29 page FILM SPECIFICATION 66 page

◐ HOW TO USE MAIN DEVICES

Feeding Area 33

page

Lamination Area 37

page

Cutting Area 38 page

Film Load / Replacement 39 page

Other Devices 41 page

Important Safety Instruction

"Important Safety Instruction " is for the purpose of user's safety

and prevention of Property loss. Read thoroughly and Use rightly according to the manual

Warning : If you ignore this symbol, you could suffer serious injury or death

Caution: If you ignore this symbol, you could receive a serious injury or loss of property

This symbol means a prohibited action. If you ignore a prohibited action, you could suffer a personal injury and damage the machine

This symbol means a required action. If you don't follow this action, your safety is not guaranteed.

Required action will be included in this symbol.

Reference: The sign above refers the contents for user's safety and prevention of Property loss.

☞ Power

Do not connect or disconnect with wet hands, as this will cause an electric shock

Do not overload a power supply, as this will cause a fire and an electric shock.

Do not use a damaged plug or lead, as this could cause a fire or an electric shock

Do not use other voltage and power supply other than specified, as this will cause a fire and an electric shock.

Make sure plug is in the socket, as it could cause fire or an electric shock

WARNING

3/66

Important Safety Instruction

It must be grounded for safety.

Otherwise, this could be a cause of trouble and electric shock.

Danger, Malfunction, loss of electricity could cause an electric shock

Do not pull the plug or bend improperly

☞ Installation

Do not use materials near a naked flame

Do not use the machine in the sealed place.

Only use the specified power and voltage. It can be a reason of fire flame or an electricity fire flame.

Do not dissemble, make repairs or convert the machine. Contact your dealer for repairs

Ensure all hair, neckties, necklaces, are kept free of the feeding table to avoid injury

Do not convert the safety device and safety switch.

Do not spill any liquids on the laminator as this will cause damage and a possible electric shock

Do not use the flammable spray or flammable materials inside or outside the machine. As this could cause a fire.

Do not allow children use of this equipment

4/66

Important Safety Instruction

☞ Power

When moving the product, turn off the power switch, disconnect the power plug from the socket

When laminator is not in use, you must turn off the power switch, disconnect the power plug from the socket.

☞ Installation

Danger - laminating blades are sharp and can cause injury.

More than 2 people are needed to carry this equipment to avoid personal injury or damage to the machine.

Keep gears and chains free of all materials

Do not touch the roller with your hand as you could be burnt.

Please avoid installing near the following places;

Gas stove, Ventilator or Air conditioner due the higher temperature or higher humidity

Do not place any materials on the laminator as they could catch a fire

Avoid the direct sunlight for the installing the machine

Make sure no vibration and dusts are found in the place during the installation.

Avoid the dark and slope place for installation

Do not place any materials on the laminator as they could catch a fire

Do not touch the film and laminating machine just after lamination finishes as you could be burnt.

Use the machine with laminating purpose only.

Tidy up the place near the laminating machine.

CAUTION

5/66

Safety Device

☞ Emergency Stop Switch

When emergency situation happened, it stops the running motor(rollers) rotation and system operation.

In case of emergency, use this switch.

☞ Position of E-Stop Switch ☞ How to use

Press the Red button to operate the Emergency Stop Switch.

All system is stopped when this is pressed.

Turn the switch to the right to release from Emergency Status.

Emergency Stop Switch

E-Stop S/W

6/66

Safety Device

☞ Laminating Roller Safety Cover

It protects the workers from the burnings that may be occurred by touching hot roller

Make sure the Safety Cover is always closed, except when Film is being loaded.

☞ Switch for Protection of Feeding Device

It prevents the damage of feeding device from feeding table

The system is not working once the safety switch is activated

by abnormal raising of feeding table as right picture.

When the lever gets it's original position, the system will be working.

7/66

WARNING STICKERS

For the user safety, in the outer design, the below sticker is attached. Be cautious not to injured during operation.

☞Roller caution ☞Higher Temperature

Do not touch the roller and heating plate with your hand as you could be burnt. Do not touch on the heating part

Roller's higher temperature and press can damage your body

☞Cutting Caution ☞Electricity Caution

Do not touch your body on the trimming device Inside the machine, high voltage flows,

You can suffer an injury

Do not open the outer case

You can suffer injury or sudden death with electricity shock

☞Chain Caution

Do not your body wound into a chain.시오.

You can suffer an injury

WARNING STICKERS

8/66

WARNING STICKERS

WARNING STICKERS

9/66

PACKING CONTENTS

ITEMS Q'TY(EA)

LAMINATOR 1

FEEDING TABLE 1

PAPER GUIDE 2

AIR COMPRESSOR 1

AIR HOSE 1

MANUAL

1

SLEEKING IDLE ROLLER ASS'Y 1

VACUM PUMP

1

SEPARATOR ASS'Y 2

AIR BLOWER ASS'Y 2

REAR GUIDE ASS'Y 2

GLASS TUBE FUSE(20MM) 250V/12.5A 4

WRENCH SET 1

SUCTION CUP 2

`

CONTENTS

PROTOPIC AUTO - 540 HS

10/66

MAIN DEVICES

Main Devices

E-Stop S/W

Feeding Table

Control Panel

Decurling

Adjustment Knob

Film Shaft Holder

Perforator

Pull Roller Pressure

Adjustment Knob

Laminating Roller Pressure

Adjustment Knob

Tray Table

11/66

MAIN DEVICES

Feeder

Rewinder

Film Tension Adjustment Knob

Rewinder Tension

Adjustment Knob

Feeder Position

Adjustment Knob

Feeder Height

Adjustment Knob

Film Shaft

12/66

MAIN DEVICES

Power S/W

Bursting Roller

13/66

MOVE & INSTALLATION

☞ Unpacking

1. Product is packed with vacuum aluminum packing materials to avoid corrosion and

external packing is wooden crate.

Each wooden panel is assembled with screws to prevent external shock

2. Wooden crate can be disassembled by 11mm box spanner.

Disassemble the 5 panels on the left picture and remove vacuum packing materials. Then,

move it to the installation place.

☞ Move the product

◑ Before it is moved

1. Unplug the power cord & air hose from the laminator.

2. Release the caster wheels and separate the height adjustable legs.

◑ In the following cases, it requires to move it by forklift.

1. If the ground is not level.

2. If it is required to be moved it to more than 10m distance.

3. After unpacking and move it to an installation area.

UNPACK & MOVE

14/66

MOVE & INSTALLATION

◑ If it requires to move it by caster wheel.

1. If a distance to move the laminator is less than 10m distance in the same area

2. Move the laminator gently with more than 4 persons at least. During it is moved, grip each corner of the machine.

◑ After the machine is moved

1. Lock the caster wheel and fix the machine with height adjustment legs.

2. Plug the power cord and connect the air hose.

3. Check the machine as the test operation.

WARNING : Machine weight is around 330 kgs, then be careful to move it to avoid damage / injury.

Before it is moved, power cord / air hose have to be unplugged / disconnected.

☞ Caster Wheel

Short moving in the same area is required.

☞ Height Adjustment Leg (Leveling Foot)

Leveling foot is to fix / to level the machine.

After the machine is moved on the installation place, fix the machine with spanner.

15/66

MOVE & INSTALLATION

☞Circumstance

1. Be installed in the flat place.

2. If inflammable or combustible substance is around, it might be a reason for a fire.

3. Sufficient ventilation is required to omit the heat from the laminator while laminating.

☞Installation Space

Demension(WxLxH) 800*1675(2345)*1320

Working Space(WxLxH) 900*2445*1500

Reference : The place for installation could be different depends on the job circumstance

LAMINATOR

800

1675

2445

900

Paper

Stacker

670

16/66

MOVE & INSTALLATION

☞ Power Connection

◐ Specification of Main Power

◐ Phase of Plug & Power Socket

Rated Voltage : 3P+N+E, 400VAC

Rated Frequency : 50/60Hz

Rated Current : 23A

◐ Phase & Voltage

1. Phase

G(GROUND)

N(NEUTAL)

L1 ( R )

L2 ( S )

L3 ( T )

2. Line Voltage

N~L1, N~L2, N~L3 : 230VAC

L1~L2, L1~L3, L2~L3 : 400VAC

Warning : If each of phases of powersupply is wrongly connected,

vacumm pump's rotation direction suddenly changed, internal components possibly have fatal damages.

Power Plug

20mm

3

4

5

2

1

Power Cord

3

4

5

2

1

3

4

5

2

1

L1(R)

L2(S)

L3(T)

N(NEUTAL)

G(GROUND)

Power Socket

3

4

5

2

1

5

4

3

2

1

17/66

MOVE & INSTALLATION

◐ Power Cable is connected directly to the Switchboard

Color&No. of Wire Wiring color

L1 ( R ) Black 1 Black

L2 ( S ) Black 2 Brown

L3 ( T ) Black 3 Black

N(NEUTAL) Black 4 Blue

G(GROUND) Green&Yellow Green&Yellow

Warning : If each of phases of powersupply is wrongly connected,

vacumm pump's rotation direction suddenly changed, internal components possibly have fatal damages.

Connection to Power

18/66

MOVE & INSTALLATION

Caution: This product consumes a large amount of electricity during its operation. If you connect this equipment with

a power cable with insufficient capacity or an old cable, a fire might break out due to electrical leakage.

Caution : For your safety, please make sure that it's grounded properly. If not, excessive static electricity will occur during operation

and it will even cause the malfunction of the equipment In case of malfunction or electrical leakage, there's possible danger for electrical shocks.

Caution : If you arbitrarily replace the power plug attached to the product, it might cause a serious problem to your safety.

When you would like to replace the plug, ask for help from the retailer or our service

Caution : Make sure the power is turned off before connecting to the source of electricity.

If not, there's possible danger for injury due to sudden operation of the equipment.

Caution : Do not connect other equipment simultaneously to the consent which is connected to our product.

Due to the excessive power consumption, a fire might break out.

Caution : If you make a wrong phase connection to the source of electricity, it might cause the damage to the equipment or start a fire.

Caution : Insert the plug deeply into the socket so that it won't shake. If not, it's a reason for a fire due to the abnormally heated consent.

Caution : The socket-outlet shall be installed near the equipement and shall be easily accessible.

Caution

Warning

Connection to Power

19/66

MOVE & INSTALLATION

☞ How to connect

Compressed air needs to be supplied into the laminator to activate the bursting roller and pressure on the laminating roller.

NOTE : A large amount of moisture is made during the air compressor is operated.

Then, the dry filter at output of compressor must be demoisturised once a day.

Power

Plug in at Independent Power System (AC 220~240V).

How to connect Air Compressor

Insert air hose in to the air compressor

After Power On, pull the cap

upward.

Press in the direction of the arrow.

Plug in at Independent Power

System

20/66

Other manuals for PROTOPIC AUTO-540 HS

1

Table of contents

Other GMP Laminator manuals

GMP

GMP SURELAM-PRO540HR User manual

GMP

GMP QTOPIC-380 User manual

GMP

GMP EXCELAM-1100SWING User manual

GMP

GMP SURELAM-PRO540HR User manual

GMP

GMP PROTOPIC III-540 User manual

GMP

GMP EXCELMASTER-1600 User manual

GMP

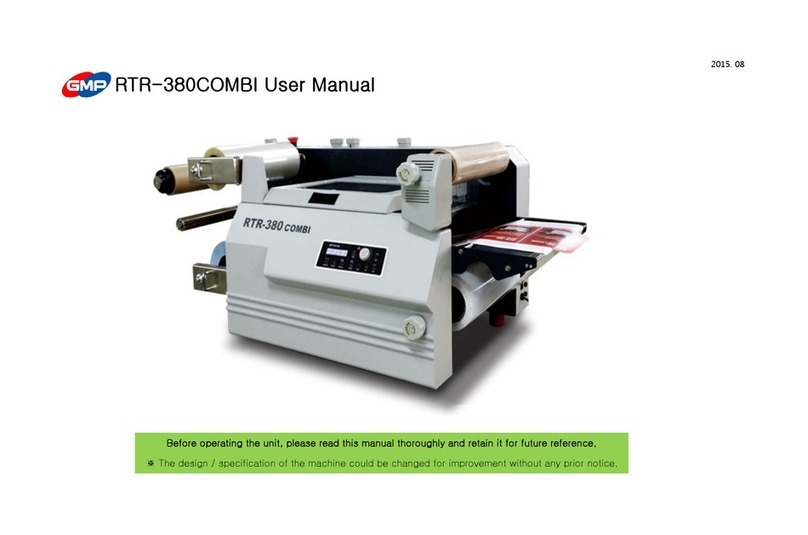

GMP RTR-380COMBI User manual

GMP

GMP PROTOPIC AUTO-540 HS User manual

GMP

GMP GraphicMaster 1600HR User manual

GMP

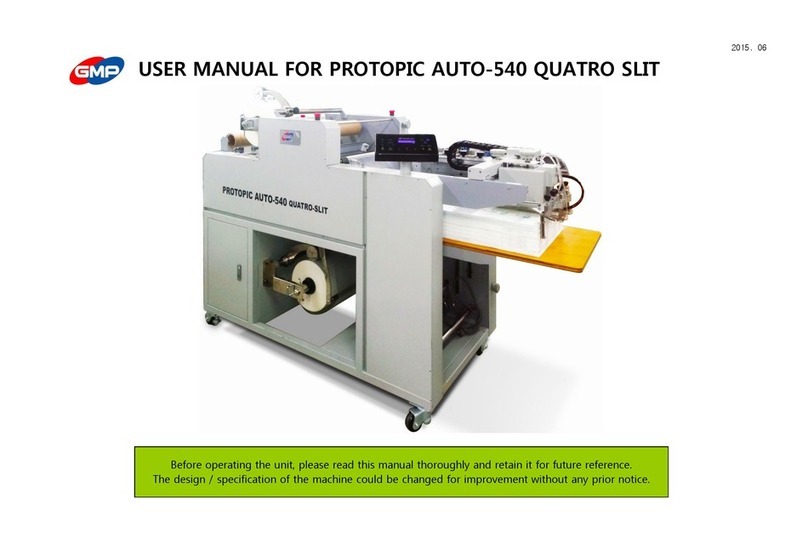

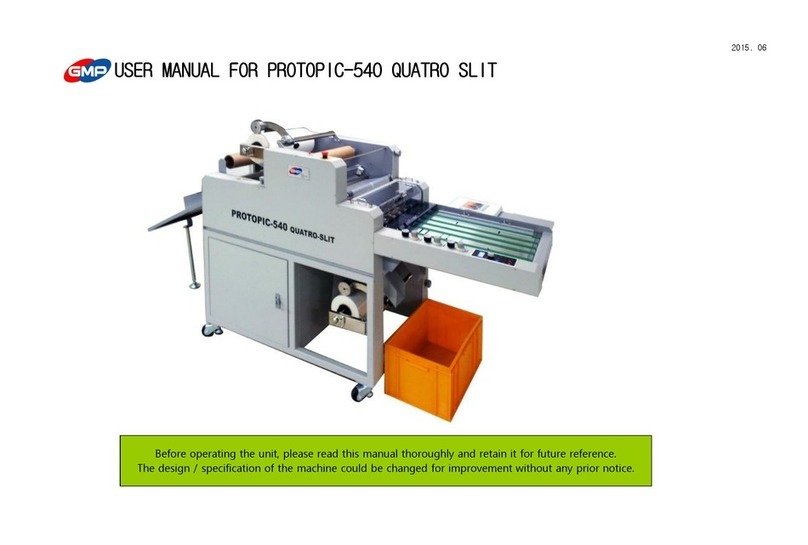

GMP PROTOPIC-540 QUATRO SLIT User manual