GMP GraphicMaster 1600HR User manual

Before operating the unit, please read this manual thoroughly and retain it for future reference.

LEADERS IN LAMINATION TECHNOLOGY

User Guide 2001.05.30

User’s Guide

Operating Instructions

Copyright GMP 2001. All rights reserved. Reproduction by any means of any image in this catalogue is prohibited without the prior consent of GMP and its authroized agent

1600HR,2100HR

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS

INSTALLATION

FEATURES

NAME OF EACH PART

OPERATION OF CONTROL PANEL

HOW TO PERFORM LAMINATION

SAFETY DEVICE

HOW TO PERFORM MOUNTING

LAMINATION GUIDE

CLEANING

TROUBLE-SHOOTING

SPECIFICATIONS

3

6

7

8

11

13

21

22

23

24

24

25

2

This safety message means that you could be burned and your fingers and hands could be

trapped an crushed in the hot rollers.

Die folgenden Warn-Hinweise finden Konnen Sie an diesem Gerat

Warnung : Gefahr eines Elektro-Schocks

Gerat nicht öffnen.

Wenden Sie sich bei Bedarf an unser qualifiziertes

Kundendienst Personal

Dieser Sicherheits-hinweis meint:Sie können ernsthaft verletzt weden, wenn Sie das Gerat offnen,

da Sie mit Hochspannung in Berührung kommen können.

Achtung : Beheizte Walzen

CAUTION : Hot Roller

This safety message means that you could injury yourself if you are not careful.

Dieser Sicherheits-Hinweis meint: Sie können sich bei Berührung der Walzen vervrennen und Thre

Finger in den hei en Walzen gequetscht werden. Kleidung, z. B. Krawatten, Schals, langes Haar,

Schmuck etc. kann von den Walzen erfa t werden und Sie in das Great hineinziehen.

Achtung : scharfe Messerklinge

Dieser Sicherheits-Hinweis meint: Sie können sich verletzen, wenn Sie nicht vorsichog mit der

Schneidevorrichtung umgehen.

CAUTION : Sharp blade.

WARNING :The safety alert symbol precedes each safety message

in this instruction manual. The symbol indicates a potential personal safety hazard

to you or others, as will as product or property damage.

General

Keep hands, long, loose clothing, and articles such as necklaces or ties away from the front of the

hot and pull rollers to avoid entanglement and entrapment. The heat shoe can reach temperatures

over 180 degree C. Avoid contact with the heat shoe during operation or shortly after power has

been removed from the laminator.

Keep hands and fingers away from the path of the sharp edges or table.

An unstable surface may cause the laminator fall resulting in serious bodily injury. Avoid quick

stops, excessive force and uneven floor surfaces when moving the laminator on a cart or stand.

Do not defeat or remove electrical and mechanical safety equipment such as interlocks, shields

and guards. Do not insert objects unsuitable for lamination or expose the equipment to liquids.

Electrical

The laminator should be connected only to a source of power as indicated in therse instructions

and on the serial plate locaated on the rear of the laminator. Contact an electrician should the

attachment plug provided with the laminator not match the receptacles at your location.

WARNING : To guard against injury, the following safety precautions must be observed

in the installation and use of the laminator.

Wichtige Sicherheits - Hinweise

34

D

USA

GB

IMPORTANT SAFETY INSTRUCTIONS

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

To prevent fire or shock hazard, do not expose the unit to rain or moisture.

This symbol is intended to alert the user to the presence of uninsulated

“dangerous voltage” whithin the product’s enclosure that may be of

sufficient magnitude to constitute a risk of electric shock to presons.

Dieses Sicherheits-Zeichen markiert einen wichtigen Sicherheits-Hinweis in diesem

Bedienungshandbuch und auch an dem Gerät.Lesen und beachten Sie diese Sicherheits-Hinweise

und die entsprechenden Bedienungsanweisungen sorgfältig.Bewahren Sie diese Hinseise fur

spatere Benutzung auf.Die folgenden Warnungen Können Sie auf dem gerat finden:

D

The safety alert symbol precedes each safety message in this instruction manual and

on the product you will find important safety messages.

Read these messages and instructions carefully. Save these instructions for later use.

The following warnings are found upon this product.

CAUTION : TO REDUCE THE RISK OF ELECTRIC SHOCK.DO NOT REMOVE COVER (BACK).

NO USER SERVICEABLE PARTS INSIDE. REFER SERVICING TO QUALIFIED SERVICEPERSONNEL

This symbol is intended to alert the user to the presence of important

operating and maintenance (servicing) instructions in the literature

accompanying the appliance.

Achtung

Gefahr eines elektrischen Schlages

Gerat bzw. Gëhause nicht offnen

Wichtige Sicherheits - Hinweise

USA

GB

Achtung :

um das Risiko eines elektrischen Schlages zu vermeiden,öffnen Sie mienals das

Gehause eines Gerates. Es befinden sich keine Geräteteile innerhalb, die Sie selber

reparieren order austauschen Konnen. Fragen Sie unbedingt qualifiziertes Service-

Personal. Dieses Symbol weist Sie darauf hin, da Innerhalb dieses geschlossenen Gehauses oder

Gerateteils eine ungeshutzte, gefahrliche Stromspannung existiert, die stark genug sein kann, Sie

durch einen elektrischen Schlag zu gefahrden.

Dieses Symbol weist Sie darauf hin, da ar dieser Stelle der Bedienungsanleitung Wichitige

Bedienungs-oder Service-bzw. Reparatur-Hinweise Vermerkt sind.

WARNING : Electric shock hazard, Do not open.No user serviceable parts inside.

Refer servicing to qualified service personnel.

This safety message means that you could be seriously hurt or killed if you open

the product and expose yourself to hazardous voltage.

Your safety as well as the safety of others is important to GMP. In this instruction manual you will

find important safety messages regarding the product. Read these messages carefully.

The following warnings are found upon this product

USA

GB

5

Upon installation...

1. Set up the unit on a leveled surface after confirming with a device for leveling.

If the operating surface is not leveled, that may cause life of the unit to be shortened.

2. This unit draws a lot of electric current at 400V/50Hz. Please make sure the power

source is with enough capacity and make sure the unit is grounded to prevent statics.

3. The capacity of an air compressor (to be purchased separately) should be at least 3/4HP

Prepareing Power Connection:

Tools needed: Flat Screw Driver or Philips Driver, Stripper

1. Female receptacle matching the 3-phase power plug is supplied with GraphicMaster.

The wire to be connected to the receptacle should be at least 3.5mm2for 1600HR and

6mm2for 2100HR.

2. Strip the jacket off each wire as shown below. The stripped copper core should be

20mm 1mm in length.

Twist the stripped copper core clockwise.

20mm

3. The Wire Connection

Insert Neutral wire and tighten with driver.

Insert L3(T) wire and tighten with driver

Insert L2(S) wire and tighten with driver

Insert L1(R) wire and tighten with driver

Preparing Air Hose Connection

1. Adaptor to be attached to the hose from the air

compressor (not included with laminator)is supplied

with laminator. (The air hose should be 8)

2. Slide back the locking collar and insert the male

adaptor from the laminator side into the female adaptor.

Release the locking collar the lock both adaptors.

Insert the yellow/green wire into the hole by

‘Ground’sign. Use a driver to tighten the wire.

WARNING!

BE EXTREMELY CAREFUL WHEN YOU UNLOCK THE ADAPTORS AS THE AIR

PRESSURE WILL REPEL THE ADAPTORS FROM EACH OTHER WITH GREAT FORCE!

Locking Collar

6

INSTALLATION

Do not operate the laminator with a damaged power supply cord or attachment plug, upon

occurrence of a malfunction, or after the laminator has been damaged, contact GMP’s Technical

Service Department or your dealer/distributor for assistance.

Service : Perform only the routine maintenance procedures referred to in these instructions.

Do not attempt to service or repair the laminator. Disconnect the plug from the receptacle

and contact GMP’s Technical Department or your dealer/distributor when one or more of

the following has been connected.

- The power supply cord or attachment plug is damaged.

- Liquid has been spilled into the laminator.

- The laminator is malfunctioning after being mis-handled.

- Laminator does not operate as described in these instructions.

CAUTION

The recepatcle must be located near the equipment and easily accessible. Disconnect

the attachment plug from the receptacle to which it is connected and keep the power

supply cord in your possession while moving the laminator.

WARNING : die folgenden Sicherheits-Hinweise unbedingt beachten, um sich wahrend der

installatiion und des Gebrauchs des Gerates gegen Verletzungen zu schutzen.

Allgemein :

halten Sie lhre Hände, lamges haar, lackere Kleidüngsstucke und Gegenstände wie Halsketten etc fern von

den vorderen hei en Rollen bzw. den Heizeschuhen, um Verbrennungen, Quetschungen oder Zerstörungen

zu vermeiden.

Der Heizschuh kann Temperaturen bis 180 errichen. Vermeiden Sie deshalb den kontakt wägrend der

Arbeit mit dem Laminator und auch kurz nachdem Sie die Stromzufugrung abgeschaltet haben.

Wenn Sie das Gerät in eine neue Position bewegen, vermeiden Sie unebene Fü Boden, plotzliche Ansto e

und ruckartige Stops. Elne unebener Untergrund kann dazu führen, da das Gerät umfallt und lhnen

korperliche Verte zungen zufügt.

Entfernen oder umgehen Sie incht elektrische oder mechanische Sicherheits-Einrichtungen wie

Schutzschalter und-abdeckungen.

Versuchen Sie keine Objekte, die zum Laminieren ungeeignet sind, in das Gerät einzufuhren.

Bringen Sie Keine Flüssigkeiten oder Feuchtigkeit in Kontakt mit dem Laminator.

Elektrizität :

Der Laminator darf nur mit einer Stromquelle in Kontakt gebracht werden, wie in dieser Anleitung

beschrieben bzw. Wie auf dem Typenschild auf der Rückseite des Gerätes vermerkt.

Verstandigen Sie auf alle Fälle einen Elektriker, wenn der am Gerät angebrachte

Strom-Stecker nicht mit der Strömzufuhrung in lhrëm Gëbaude übereinstimmt.

Vorsicht : Der Stromanschlu mu in der Nahe des Gerätes und jederzeit leicht zugänglich sein.

Wenn Sie das Gerät bewegen, ziehen Sie auf alle Fälle den Stecker aus der

stromzufuhrung und befestigen sie ihn an dem Gerät, damit er nicht beschadigt wird

oder die Bewegung behindert.

Arbeiten Sie niemals einer beschädigten Stromzuführung; setzen Sie sich in diesem Falle

mit dem GMP Kundendienst oder lhrem Handler in Verbindung.

Kundendienst : führen Sie nur routinemä ige Überprüfungs- und Reinigungsarbeiten durch,

wie sie in der Bedienungsanleitung beschrieben sind.

Versuchen Sie nie im Falle einer Betriebsstörung, das Gerät seiber zu reparieren

oder den Fehler zu suchen. Ziehen Sie den Stecker aus der Steckdose und

informieren Sie, - insbesondere in den nachfolgenden Fällen, - das technische

Personal von GMP oder lhrem Händler.

- der Geräte- Strom- Stecker bzw, das Stromkabel sind bexchadigt

- Flüssigkeit ist in den Laminator geraten

- der Laminator hat eine Funktionsstörung nach einem Bedienungsfehler

- der Laminator arbeitet nicht entsperchend den Beschreibungen dieser

Bedienungsanleitung

D

7

NAME OF EACH PART

A

B

C

D

E

F

G

H

I

J

M

K

L

N

A Hot Roller

B Control Panel

C Front (Feed) Table

(Vacuum Table)

D Emergency Switch

E Cross Beam

F Lower Laminating Film

G Unwinder(Front - Bottom) :Optional

H Side Cover

I Top Rewinder

J Top Laminating Film

K Air Pressure Gauge

L Roller Air Pressure Regulator

M Top Unwinder: Optional

N Cooling Fan: Optional

O Feed Basket: Optional

P Top Rewinder Tension Adjuster Hole

Q Front Bottom Unwinder Tension

Adjuster Hole

R Rear Bottom Rewinder Tension

Adjuster Hole

* All the ‘Optional’ items mentioned above

are standard items for 2100HR

A Emergency Switch

B Rear Cross Trimmer

C Rear Bottom Rewinder: Optional

D Power Panel

E Top Laminating Film

F Idle Bar

G Caster

H Air Filter

I Stretch Bar

O

P

Q

R

A

E

F

B

G

D

C

H

From the GMP Stable comes a brand new concept in Hot & Cold Laminating, Mounting.

The GMP GraphicMasterTM has been designed to meet the needs of the developing

Graphics Reproduction Market. Incorperated in one design is a multi-functional machine

which laminates single or both sides, using hot and cold films, then mount onto a wide

variety of materials including foamboard, polystyrene board & any other board.

Pneumatic (Air) Pressure Control for Roller Pressure Adjust

Electronic/Pneumatic Roller Gap Control (Max.Gap 30mm)

Vacuum Table for easy handling of material to be laminated

- Vacuum fans prevents deformation of material to be laminated (mostly inkjet media)

by cooling off the table. (The Vacuum Table tends to be hot from the heat generated

from the laminator.)

Enhanced and Simplified Control :

- VFD (Vacuum Fluorescent Display) Control Panel

- Jog Dial for Top Temp, Bottom Temp, Speed Control & Job Mode

- Multi-functional Foot Switch : Depending on the number of steps, switching function

from Roller Engage, Roller Release, Reverse, etc.

Removable rear cross - web trimmer

3” (77mm) Core Chucks by Aluminium Die-casting for Easy Tension Control

Stretch Bar between Hot and Pull Rollers to eliminate ripples or waves on laminated web.

FEATURES

< Optional Features >

Secondary Top Unwinder for loading extra roll film.

Side Slitters for in-line side trimming

Feed Basket on Feed Table for loading long length media into laminator

Cooling Fans for cooling off laminated web in order to perform uninterrupted,

continuous lamination.

Front-bottom Unwinder, Rear-bottom Rewinder for Roll-to-Roll Lamination.

8

Be careful of the followings...

1. This unit has rather fast vertical roller movement for gap adjustment by using air

pressure. Avoid any body part from the roller nip area.

2. There are infrared optic temperature sensors near each hot roller. Make sure there is

no foreign object between the rollers and the sensors.

3. Upon loading/unloading laminating film on/off the unit, do not do that alone since the roll

films may be heavy.

4. Refrain from dressing up in loose clothing or wearing tie upon operating the unit.

It is recommended to have hair bundled up if a operator has a long hair.

5. Make sure the unit is connected to proper air pressure before turning the power on.

Not enough air pressure may cause mal-functioning of the unit.

I

Power Panel Lay-out

Power Switch

(Circuit Breaker)

Power

Cord

Foot S/W Cord

Laminator Motor

Fuse 250V / T6.3AL

Control Panel Lay-out

Vacuum Fan

Fuse 250V / T4AL

Transformer AC9V

Fuse 250V / T3.15AL

Transformer AC18V

Fuse 250V / T3.15AL

Transformer Primary

Fuse 250V / T6.3AL

Cooling Fan

Fuse 250V / T6.3AL

OFF

ON

9

Cross Slitter Control Panel

Emergency Switch

Top Unwinder(Optional)

Roller Pressure Gauge

Cooling Fan

(Optional)

Air Filter

Drive Motor

Stretch Bar

Side Slitter(Optional)

Pressure Regulator

10

FRONT ROLLER PRESS / RELEASE : Push to close or release the roller gap

VACUUM : Toggles between turning on the vacuum fans, installed inside the front table,

and turning them off.

COOLING : Toggles between turning on the cooling fans, installed under the laminating web,

and turning them off.

START : Push to start running the unit

STOP : Push to stop running the unit

REVERSE: Push to run the unit in reverse. Keep it pressed to keep it running in reverse and

audible beep will sound while pressed

Select Key & Jog Dial

Controls

This part is to control the laminating

speed and mode of the unit. Should

operator desire to change the Top

Temperature, press TOP

TEMPERATURE key and turn the

Jog Dial left or right to set the

desired temperature. LED on left of

those keys shown will indicate if that

particular setting is chosen to

change. Turning the Jog Dial will

change only the setting by where

LED is lit.

TOP TEMPERATURE

BOTTOM TEMPERATURE

SPEED

JOB MODE

Control Buttons

11

OPERATION OF CONTROL PANEL

TEMPERATURE Display

Top & Bottom temperature can be displayed and set from 0~160

SPEED Display

Laminating speed can be set from 1 to 10 (relative scale) corresponding to minimum to

maximum of 3m/min for 1600HR and 5m/min for 2100HR.

RUN TIME Displays

Displays time the unit has gone under operation. It will be re-set to “00:00” once the power

of the unit is turned off.(“Hours:Minutes”)

MODE Displays

Shows various laminating and mounting modes and all the major laminating parameters

such as roller temperature, roller gap, speed, fan power will be adjusted accordingly.

A. High-Prs Lami B. Mid-Prs Lami C. Low-Prs Lami D. 03mm Mounting

E. 05mmMounting F. 07mmMounting G. 10mmMounting H. 15mmMounting

I . 20mmMounting J. 25mmMounting

For cold lamination, there is no pre-set setting programmed in the laminator.

Operator should manually set the temperature to 40 at the Mid-Prs”pre-set.

Note) Cold Film thickness less than 50mic : “High-Prs”mode

Cold Film thickness over 200mic : “Low-Prs”mode

Message Display

Generally shows the temperature of each top & bottom roller and changes according to

the status of the unit setting. Details will be reviewed again later on.

Vacuum Fluorescent Display (VFD)

MODEL

GraphicMaster-1600HR

GraphicMaster-2100HR

1 2 3 4 5 6 7 8 9 10

0.4 0.7 1.0 1.3 1.6 1.85 2.1 2.4 2.7 3.0

0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

(m/min)

12

03mm Mounting

TOP> 0 0 0 C S P E E D > 0 5

BOT>0 0 0 C R / T > 0 0 : 0 0

MODE> 0 3 mm M o u n t i n g

P o s i t i o n i n g . . .

05mm Mounting

TOP> 0 0 0 C S P E E D > 0 5

BOT>0 0 0 C R / T > 0 0 : 0 0

MODE> 0 5 mm M o u n t i n g

P o s i t i o n i n g . . .

07mm Mounting

TOP> 0 0 0 C S P E E D > 0 5

BOT>0 0 0 C R / T > 0 0 : 0 0

MODE> 0 7 mm M o u n t i n g

P o s i t i o n i n g . . .

In order to perform cold lamination at above 3 settings, please follow as below:

TOP> 0 4 0 C S P E E D > 0 5

BOT>0 4 0 C R / T > 0 0 : 0 0

MODE> M i d - P r s L A M I

W A I T ( T o o H O T )

All the factory-set parameters can be over-ridden (except the pressure setting)

according to operator s needs.

1) Performing Cold Lamination right after Hot Lamination (when the laminator is still hot):

TOP> 0 4 0 C SPEED>05

BOT>0 4 0 C R / T > 0 0 : 0 0

MODE> M i d - P r s L A M I

READY

2)

Performing Cold Lamination (except mounting) right after switching on the power of the unit:

By using the Jog Dial, set the roller temperature down to 40 at “Mid-Prs” mode

(recommended temperature for cold lamination) and the speed to 5 at the current mode.

Then start cold lamination (after loading the proper films and materials for cold

lamination) when “WAIT (Too HOT)” is display is switched to “READY.”

Select “Mid-Prs” mode at ‘Job Mode.’ Set the roller temperature to 40 and the speed

5 by using the Jog Dial, and start lamination when “READY” is displayed on the VFD.

Suggestion: film thickness<50mic: “High-Prs,” film thickness>200mic: “Low-Prs”

13

HOW TO PERFORM LAMINATION

Press Job Mode when machine is idle. By turning the Jog Dial, you can set the

machine under following conditions.

A. High-Prs LAMI B.Mid-Prs LAMI C.Low-Prs LAMI D.03mm Mounting

E.05mm Mounting F.07mm Mounting G.10mm Mounting H.15mm Mounting

I.20mm Mounting J.25mm Mounting

Changing Job Mode

How to web the laminating films on the unit for Hot Lamination.

MEDIA IN

Roll Film (Top)

Pull Roller

Heating Roller

Idle Roller

Stretch Bar

Roll Film (Bottom)

Please refer to below diagram

1.High-Prs Lamination (Hot & Cold Lamination)

TOP> 1 1 0 C S P E E D > 0 4

BOT>1 1 0 C R / T > 0 0 : 0 0

MODE> H i g h - P r s L A M I

P o s i t i o n i n g . . .

2.Mid-Prs Lamination (Hot & Cold Lamination)

TOP> 1 1 0 C S P E E D > 0 5

BOT>1 1 0 C R / T > 0 0 : 0 0

MODE> M i d - P r s L A M I

P o s i t i o n i n g . . .

3.Low-Prs Lamination (Hot & Cold Lamination)

TOP> 1 2 0 C S P E E D > 0 2

BOT>1 2 0 C R / T > 0 0 : 0 0

MODE> L o w - P r s L A M I

P o s i t i o n i n g . . .

14

IMPORTANT NOTE:

1. Make sure the vacuum fans

are on in order for the material

to be laminated to ‘stick’ to the

the vacuum table, to be wrinkle

& wave-free and to prevent the

table to be over-heated/

2. It is strongly recommended

that the laminated web to be

run over the Strech Bar for the

laminated result to be

straightened out and be free of

waves.

Setting the Temperature

1) How to set the Temperature

Press ‘TOP TEMPERATURE’ key or ‘BOTTOM TEMPERATURE’ key on the control panel

and turn the Jog Dial left or right to set the desired temperature. Once the temperature

is selected, the setting will automatically stored in the memory after 2 seconds.

2) READY and WAIT Display

READY means the actual temperature has reached the set(target) temperature.

Push the ‘START’ button to start operating. If the actual temp. becomes lower than the

set temp.,‘WAIT(Too COLD)’ will be displayed and ‘WAIT(Too HOT)’ will be displayed

in opposite case. In any case, wait till ‘READY’ comes on in order to operate the unit.

TOP> 1 1 0 C S P E E D > 0 5

BOT>1 1 0 C R / T > 0 0 : 0 0

MODE> M i d - P r s L A M I

W A I T ( T o o C O L D )

TOP> 1 2 0 C S P E E D > 0 5

BOT>1 2 0 C R / T > 0 0 : 0 0

MODE> L o w - P r s L A M I

W A I T ( T o o H O T )

TOP> O V E R H S P E E D > 0 5

BOT>O V E R H R / T > 0 0 : 0 0

MODE> M i d - P r s L A M I

W A I T ( T o o H O T )

3) Roller Over-heating

The unit display “OVERH(OVER HEAT)” when the actual temp. exceeds 160 .

Release the rollers and turn off the unit power, then contact GMP agent for support.

* T O P > 1 1 0 C S P E E D > 0 5

* B O T > 1 1 0 C R / T > 0 0 : 0 0

MODE> M i d - P r s L A M I

W A I T ( T o o C O L D )

4) Actually Roller Temperature Display (Measure Temp. Function)

‘*’mark will flash while the Jog Dial is pressed to measure current temperature.

15

TOP> 1 1 0 C S P E E D > 0 4

BOT>1 1 0 C R / T > 0 0 : 0 0

MODE> H i g h - P r s L A M I

P o s i t i o n i n g . . .

Top Temp, Bottom Temp, Speed, Roller Pressure, Vacuum Fan Power, Cooling

Fan Power will all vary on their own depending on above settings. It takes from 1

to 10 seconds for the unit to set the proper roller gap when the mode is changed

TOP> 1 2 0 C S P E E D > 0 5

BOT>1 2 0 C R / T > 0 0 : 0 0

MODE> L o w - P r s L A M I

P o s i t i o n i n g . . .

10mm Mounting

TOP> 0 0 0 C S P E E D > 0 5

BOT>0 0 0 C R / T > 0 0 : 0 0

MODE> 1 0 mm M o u n t i n g

P o s i t i o n i n g . . .

15mm Mounting

TOP> 0 0 0 C S P E E D > 0 5

BOT>0 0 0 C R / T > 0 0 : 0 0

MODE> 1 5 mm M o u n t i n g

P o s i t i o n i n g . . .

20mm Mounting

TOP> 0 0 0 C S P E E D > 0 5

BOT>0 0 0 C R / T > 0 0 : 0 0

MODE> 2 0 mm M o u n t i n g

P o s i t i o n i n g . . .

25mm Mounting

TOP> 0 0 0 C S P E E D > 0 5

BOT>0 0 0 C R / T > 0 0 : 0 0

MODE> 2 5 mm M o u n t i n g

P o s i t i o n i n g . . .

Mode will be changing as per each mounting thickness settings

Note) When you perform Hot Laminating with Mounting Board (EX:GMP Foam

Pouch), Top Roller Temp. 100 (Recommended Temperature) and set the

Mounting Board thickness & speed.

16

None of the buttons, except ‘START’ key, can be activated during the Stand-by and

Power-off mode. Pressing the ‘START’ key will switch the unit to the mode before

Stand-by mode.(‘Normal’ mode)

TOP> 1 1 0 C S P E E D > 0 5

BOT>1 1 0 C R / T > 0 0 : 0 0

MODE> M i d - P r s L A M I

Coo l i n g P O W E R > 0 6

Cooling power is also one of the parameters of Job Mode, and called back along with

other settings stored together at the time.

When both the laminating film and material are thin, optional lamination result can be

obtained with only little or no amount of cooling.

Stand-by Function

The unit will switch itself to Stand-by mode when the laminator has been left idle

with none of the buttons has been pressed for more than 2 hours. (This is discounting the

time when the rollers were still rotating) The temp.of rollers will drop to 80 if it was

higher than that before. If the unit again stays idle more than 2 hours at the Stand-by

mode, it will be switched to Power-off Mode with the rollers temp. being set to 0 . Both

modes will be indicated as following (flashing) on VFD.

TOP> 1 2 0 C S P E E D > 0 5

BOT>1 2 0 C R / T > 0 0 : 0 0

MODE> L o w - P r s L A M I

Stand-by S t a t u s !

TOP> 1 2 0 C S P E E D > 0 5

BOT>1 2 0 C R / T > 0 0 : 0 0

MODE> L o w - P r s L A M I

P o w e r - O f f S t a t u s !

IMPORTANT NOTICE!

Difference in Operation with and without Cooling Fans

(For instance, laminating 100g paper with 75mic film at 100 , Speed 5, Mid-Pressure

position)

Without Cooling Fans: Can operate for 20 minutes continuously. After that, wavy

lamination result may be observed. For better result reduce the temperature to 90 ,

and the speed to 1 or 2.

With Cooling Fans(Optional): Can operate continuously under most of the settings.

The operation time may vary depending on the roller temperature and speed setting.

17

TOP> 1 0 0 C SPEED>05

BOT>1 0 0 C R / T > 0 0 : 0 0

MODE> M i d - P r s L A M I

P o s i t i o n i n g . . .

5) Heating Up Display

“ ”mark will flash while the heater is being heated

Laminator Speed Control

TOP> 1 2 0 C S P E E D > 0 5

BOT>1 2 0 C R / T > 0 0 : 0 0

MODE> L o w - P r s L A M I

R E A D Y

Press ‘SPEED’ button on the control panel and turn the Jog Dial left or right to set the speed.

TOP> 1 2 0 C SPEED>05

BOT>1 2 0 C R / T > 0 0 : 0 0

MODE> L o w - P r s L A M I

Vacuum P O W E R > 0 5

Vacuum Power is one of the parameters of Job Mode and can be stored and called back

along with other settings stored together at the time.

Cooling Fan Function (Optional on 1600HR)

The purpose of Cooling Fan is to prevent deterioration of lamination quality when the laminating

was performed under high speed since the laminated web will not cool off fast naturally under

high speed.

Push ‘COOLING’ key then the cooling fans will start while the LED next to the button is lit.

Press it once more then the fans will stop and the LED will be off. You can change the cooling

fan power by turning the Jog Dial while the ‘COOLING’ button is pressed. Following will be

displayed on VFD.

VACUUM FAN function

It is for the material to be laminated, which can be rather large for this type

of laminator, to stay on the table flat so the operator can feed the large size material into the

unit easily. The other purpose is to cool off the Front Table heated by the Hot Roller right in

front of it. Push ‘VACUUM’ key then the vacuum fans will start while the LED next to

the button is lit. Press it once more, then the fans will stop and the LED will be off. You can

change the vacuum fan power by turning the Jog Dial while the ‘VACUUM’ button is pressed.

Following will be displayed.

18

Front Table (Vacuum Table)

GraphicMaster series are built so that the user only has to fold up the table, rather than

taking off the table, in order to load the laminating films on the unit.

‘START’ button will be inactive while the table is in folded position with VFD Control Panel

displaying “Folded Front Table.”

The button becomes active once the table is put back to original position.

TOP> 1 0 0 C S P E E D > 0 5

BOT>1 0 0 C R / T > 0 0 : 0 0

MODE> L o w - P r s L A M I

F r o n t T a b l e F o l d e d !

Warning : If the Foot Switch is to be used in order to run the machine with the table folded,

be extremely cautious of the roller nip.

Auto Pressure Release Function of the Front Roller

If the hot rollers remain closed more than 4 minutes under temp. over 80 , warning beep

will sound for one second. If it lasts over 5 minutes overall, the unit will release the nip

automatically. This function is to protect the silicone rubber rollers and will not release

the press (rear) rollers.

Air Regulator

This is useful when operator wants to control the air flow going into laminator from external

air compressor (not included).

The adjustment range is from 0 to 0.7MPa although it may vary depending on the capacity

of the compressor (3/4HP compressor recommended) It can be usually set at 0.5MPa for

normal operation and minimum operatable setting is 0.2MPa for proper lamination.

If a bow-like wave is observed in the middle of the laminated web, adjusting the pressure

down to 0.3 or even to 0.2 may get rid of it. (But at the same time air bubbles may appear

on laminated film-to-film edges, which can be trimmed off after lamination)

Function of the Stretch Bar

This is installed in all GraphicMaster-1600HR and 2100HR as a standard feature and it

helps to get rid of the bow-like wave on the laminated web. Directing laminated web over

the Strech Bar is strongly recommended for all hot lamination work, specially for long,

continuous operation.

19 20

TOP> 1 1 0 C S P E E D > 0 5

BOT>1 1 0 C R / T > 0 0 : 0 0

MODE> M i d - P r s L A M I

R E A D Y

RUN TIME Display

Once the unit starts to run, the Run Time Counter will be activated.

It is displayed in ‘Hours : Minutes’ format and “:” will flash every 0.5 seconds.

Foot Switch Function

GraphicMasterTM series are with added various foot switch functions for convenience.

If an operator is familiar with all the foot switch functions, all the basic functions can be

performed by only operating foot switch.

Warning : Be careful of the nip area since the safety photo-eyes will be de-activated

when the machine is operated with foot switch.

1) ‘Start’ by using Foot Switch

To make it run forward: Press once and keep it pressed. To stop, just release.

Be aware that the photo-eyes are de-activated while the unit is running by operation

of foot switch.

2) ‘Roller Press / Continuous Start / Stop’ using Foot Switch

When front rollers and rear rollers are disengaged:

Press once then all the rollers will be engaged.

When front rollers are disengaged and rear rollers are engaged and machine is idle:

Press once then machine will start to run with front rollers engaged.

When the machine is not running: Press once then machine will start to run.

When the machine is running: Press once then machine will stop

When pressed once continuously: Machine will run while pressed, but it is ignored by

Photo-eyes

3) ‘Reverse Run’ using Foot Switch

Press once & release, then keep it pressed.

To stop,just release

4) Front Roller Release using Foot Switch

Press twice in sequence

5) Rear Roller Release using Foot Switch

Press three times in sequence.

If the unit doesn t react immediately by using the foot switch, pause about 2

seconds and try again.

2) If the unit detects usually thick material in the nip area while the Front Rollers are

being pressed, the unit will swiftly release the rollers again.

This is to prevent the case of operator’s hands being caught in the nip of the rollers.

Warning: Be careful of the nip area since there is over-ride on the function of

safety photo-eyes when the machine is operated with foot switch.

HOW TO PERFORM MOUNTING

Trim single self-adhesive Foam Board and the cold film about 10mm bigger than

image. Peel off the liner from top edge of Foam Board and fold up at about 1 (25mm).

(Diagram A)

Take the image and press against where the sticky surface is exposed on the Foam

Board carefully. (Diagram B)

Feed the combination into the laminator under 5mm mounting mode and stop the

unit after about 20mm. Then take the hold of the liner. When you re-start the

laminator, keep holding the liner and peel it off at same speed as the laminator

speed. Otherwise, the image will stick onto the Foam Board before it gets mounted.

After completion of image mounting, you can over-laminate it using

PRONEX UV Cold Film from GMP. Peel off the liner from top edge of

the film and fold up at about 1”(25mm)

Take the the film and press the sticky side against the image carefully.

Feed the new combination into the laminator under 5mm mounting

mode and stop the unit after about 20mm. Then take the hold of the

liner. When you re-start the laminator, keep holding the liner and peel it

off at same speed as the laminator speed. Otherwise, the film will stick

onto the image before it gets laminated.

10mm 10mm

Choose appropriate Job Mode for mounting operation by choosing one of the pre-set

settings under Job Mode. Press ‘JOB MODE’ button and select desired setting by turning

the Jog Dial.

TOP> 0 0 0 C SPEED>05

BOT>0 0 0 C R / T > 0 0 : 0 0

MODE> 0 5 mm M o u n t i n g

P o s i t i o n i n g . . .

A.03mm Mounting

B.05mm Mounting

C.07mm Mounting

D.10mm Mounting

E.15mm Mounting

F. 20mm Mounting

G.25mm Mounting

Job Mode Sequence Choose a desired mounting mode by using the Jog Dial

1”

21 22

This is to protect operator s hands against

the roller nip and functions as follows:

1) “Photo-eye Interrupt” will be displayed on

the VFD Control Panel with the unit stop

running if any object that is bigger than

the material normally to be laminated

blocks the both sensors.

Then START button can be activated.

Photo-eye Sensor

TOP> 1 2 0 C S P E E D > 0 5

BOT>1 2 0 C R / T > 0 0 : 0 0

MODE> L o w - P r s L A M I

P h o t o e y e I n t e r r u p t !

Once the Photo-eye Interrupt message appears, operator can not run the unit by pressing

‘START’ button anymore. Start running the unit by using foot switch or by removing the

object blocking the both sensors utilizing ‘REVERSE’ button.

If the material to be laminated is wavy or wrinkled on the Front Table before entry for

lamination, Photo-eye will be activated and the Hot Rollers will release.

Once such material is removed from the nip area, the rollers can be closed again by

pressing Front Rollers ‘PRESS’ button.

Warning : Be careful of the nip area since there is over-ride on the function of safety

Photo-eye when the machine is operated with foot switch.

SAFETY DEVICE

This will stop the unit from running when pressed under emergency circumstance.

The unit will not run while this switch remains pressed. Any attempt to make unit run while

this switch is pressed will result in only making the VFD to display “Pressed E-S/W!”

Emergency Switch

When it is safe to run the unit again, release the red emergency switch by twisting it lightly.

Then ‘START’ button can be activated.

TOP> 1 2 0 C SPEED>05

BOT>1 2 0 C R / T > 0 0 : 0 0

MODE> L o w - P r s L A M I

E - S w i t c h P r e s s e d !

Mounting and Cold Laminating with Foam Board and PRONEX UV Cold Film:

Diagram A

Diagram B

CLEANING

When laminating, a small amount of adhesive will squeeze out between the laminating films and onto the

top and bottom rollers. This residue accumulates through normal use and can be easily cleaned off the rollers.

Use only isopropylen alcohol to clean the rollers and

not other cleaners or solvents.

To clean the rollers:

- Use an eraser to remove excess glue. After the rollers have cooled to approximately 80 degrees,

use a cotton cloth and isopropyl petroleum to wipe the roller clean.

- The rollers should be cleaned every day or the heat-activated adhesive will soak into them.

If these recommendations are not followed, the rollers may develope

flat spots and these will affect the output.

To maintain the GraphicMaster Series

- When the feed table away from the heated rollers.

When the machine is not used, the rollers must either be separated by adjusting the handle or turning

if they are together. To maintain even heat distribution, the rollers should be turning together.

TROUBLE-SHOOTING

Problem

The machine is not heating

up or has erratic temperature

The film is coming out

rippled or wavy

The machine will not run

The filmis cloudy or mottled

Material is rippling or

jumping as it is being fed

The roller are not raising

or descending

Solution

The rollers should be together with no handle adjustments and turning

at a moderate speed when firsst heating up.

Make sure the machine is webbed dorrectly. See the web digrams.

There may be improper film tension.

GMP laminating films will work with a minimal amount of brake tension.

Use the cooling fans for long runs.

If you are using photo materials, Inkjet prints, run the laminator

at a higher speed.

Make sure the photo safety eyes are not blocked.

Make sure the speed selector is turned up.

Reat the emergency stop buttons.

Increase the roller temperature or cecreas the machine’s runing speed.

If the mottling is seen primaily with heavier laminating films, higher

roller pressure (heated rollers) may be necessary due to the

thicker adhesive layer.

Table should be pulled away from the geated rollers.

Plotter prints need to be tensioned as they are fed into the laminator.

Cut sheets must be held back.

Maintenance of safety personnel only should attempt each of the

following procedures

When the laminator is not in use, alwasy release the gap between the rollers

to prevent flat spots on rollers from developing.

23 24

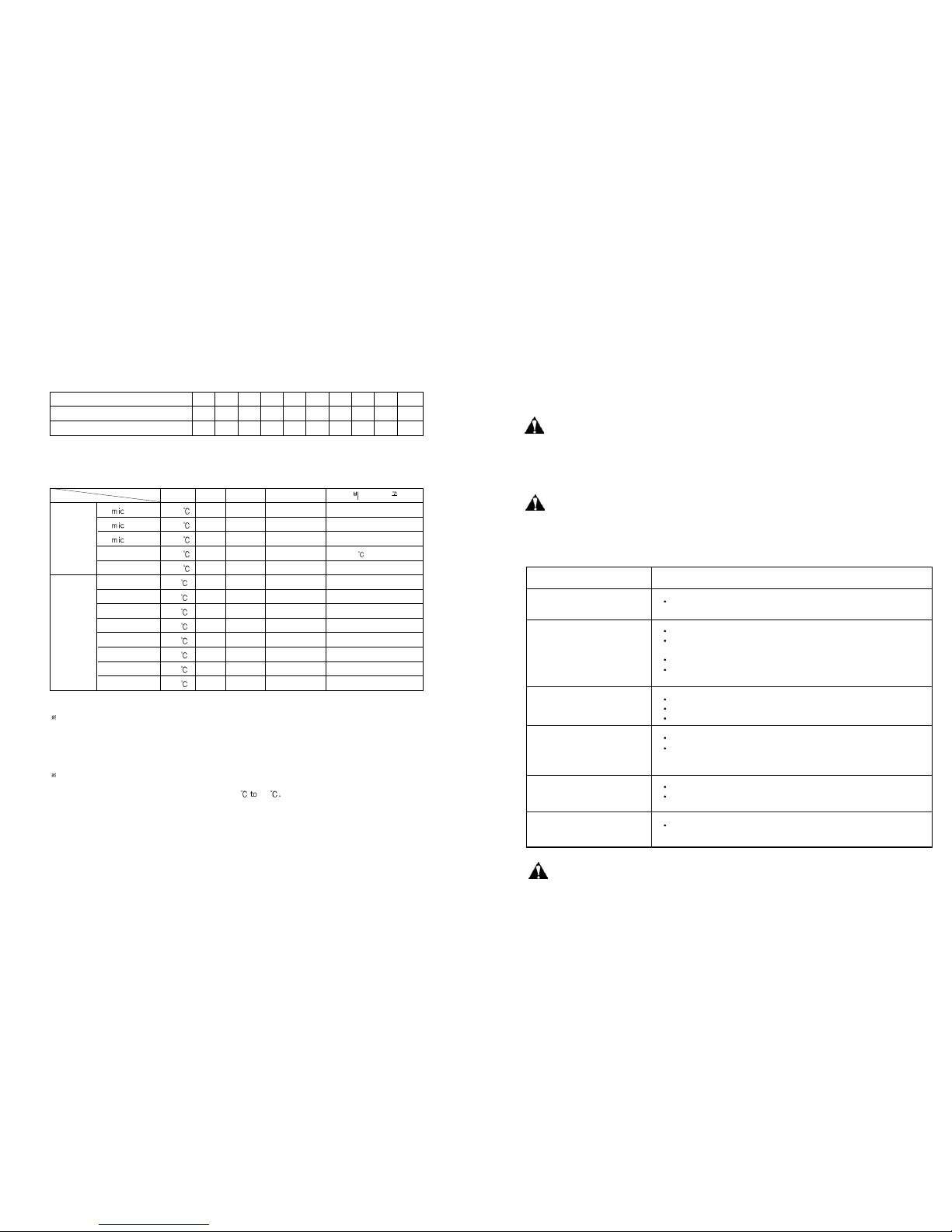

GENERAL LAMINATION GUIDE

32 (12/20)

32 (12/20)

75 (12/63)

125mic (25/100)

250mic (50/200)

COLD

3 mm

5 mm

7 mm

10 mm

15 mm

20 mm

25 mm

Mid-Prs LAMI

High-Prs LAMI

Mid-Prs LAMI

Mid-Prs LAMI

Low-Prs LAMI

Mid-Prs LAMI

3mm Mount

5mm Mount

7mm Mount

10mm Mount

15mm Mount

20mm Mount

25mm Mount

Lower by 5 after 10 min. operation

Requires Cooling Fan

Temp Speed Paper Mode

Hot

Lamination

Cold

Lamination

&

Mounting

105

100

100

100

115

40

40

40

40

40

40

40

40

6

5

4

4

3

5

5

5

5

5

5

5

5

~120mic

150mic~

-

-

-

-

-

-

-

-

-

-

-

All above is for not using Cooliong Fans

- Without cooling fans, the units can be operated for 20 minutes continuously.

But after 20 minutes the actual temperature may rise above the set temperature

(The laminated web may be some what crooked without cooling fans after long operation.)

- Continuous operation is possible with GraphicMaster laminators with Cooling Fan option.

Upon cold lamination with PRONEX UV Cold Film, silvering (appearance of white dots) may be

observed. That will disappear in about 4 hours time when left on its own. Immediate removal is

possible by performing cold lamination around 40 60

LAMINATING SPEED

MODEL

GraphicMaster-1600HR

GraphicMaster-2100HR

1 2 3 4 5 6 7 8 9 10

0.4 0.7 1.0 1.3 1.6 1.85 2.1 2.4 2.7 3.0

0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

(m/min)

LAMINATION GUIDE

25

SPECIFICATIONS

Classifications

Power Consumption (Watts)

Dimension (W LH) mm

Max.Laminating Width (mm)

Heating System

Temperature Control

Weight (kg)

Operating Temperature ( )

Max. Laminating Speed (m/min)

Power Supply

Infrared Heater

Proportional Control by 8-bit Microprocessor (IR Sensor)

380~400V / 50~60Hz : 3 Phase

GraphicMaster-1600HR

7,500

2110 x 850 x 1395

1670

820

0~160

3

GraphicMaster-2100HR

12,000

2800 x 994 x 1540

2240

1,050

0~160

5

1

LAMINATION GUIDE

Suitable for ColorSpan, Encad, EPSON, HP prints

or other prints that doesn’t laminate with normal hot film

POP-UP DISPLAY (COLD APPLICATION)

TOP : 75 mic PRONEX UV COLD Sand, Matt,

SoftMatt, Gloss

MEDIA : Inkjet Print on 200mic

JETEL-LIGHT PROTECT media

TOP : 150 mic CHROMONEX UV Sand, Matt, Gloss

or 250 mic PERFEX Gloss, Matt

MEDIA : Off-set Prints, Inkjet or Electrostatic Prints

BOTTOM : 250 micron LIGHT PROTECT or

250 micron BLK/OPQ or

250 micron PERFEX Gloss

Suitable for making general display or with prints not

stuitable with use of cold laminating film.

POP-UP DISPLAY (HOT APPLICATION-1)

Suitable for ColorSpan, Encad, EPSON, HP prints

or other prints that doesn’t laminate with normal hot film

ROLL-UP DISPLAY (COLD APPLICATION)

TOP : 75 mic PRONEX UV COLD Sand, Softmatt,Matt

Glossy

MEDIA : Inkjet Print on 75mic JETEL-LIGHT PROTECT

media

TOP : 150 mic CHROMONEX Sand, Matt or Gloss

MEDIA : Off-set Prints, Inkjet or Electrostatic Prints

BOTTOM : 75 or 125 mic LIGHT PROTECT Film or

125 mic BKC/OPQ

Suitable for making general display or with prints not

stuitable with use of cold laminating film.

ROLL-UP DISPLAY (HOT APPLICATION)

ROLL-UP DISPLAY

Various types of displays can be created for making effective

presentation by utilizing whole range of special laminating films

made for graphics display from GMP.

Depending on the purpose and application, selection of film

material and thickness can make optimal presentation possible.

2

TOP : 150 mic CHROMONEX UV Sand, Matt, Gloss

or 250 mic PERFEX Gloss, Matt

MEDIA : Inkjet Print on 200mic

JETEL-LIGHT PROTECT media

Suitable for making general display or with prints not

stuitable with use of cold laminating film.

POP-UP DISPLAY (HOT APPLICATION-2)

TOP : 150 mic CHROMONEX UV Sand, Matt or Gloss

MEDIA : Inkjet Print on 75mic JETEL-LIGHT PROTECT media

Suitable for ColorSpan, Encad, EPSON, HP prints

or other prints that doesn’t laminate with normal hot film

OUT-DOOR DISPLAY (COLD APPLICATION)

TOP : 75 mic PRONEX UV COLD Sand,Matt,SoftMatt,Gloss

MEDIA : Inkjet Print on 175mic JETEL-BACK LIGHT media

Inkjet Print on 100mic JETEL-BACK LIGHT media

TOP : 150 mic CHROMONEX UV Sand,Matt,Gloss or

150 mic PERFEX UV Gloss

MEDIA : Off-set Prints, Inkjet or Electrostatic

BOTTOM : 250 mic LIGHT PROTECT Film or

125 mic LIGHT PROTECT Film or 250 mic BLK/OPQ or

250 mic LIGHT PROTECT Film

Suitable for making general display or with prints not

stuitable with use of cold laminating film.

OUT-DOOR DISPLAY (HOT APPLICATION)

Suitable for ColorSpan, Encad, EPSON, HP prints

or other prints that doesn’t laminate with normal hot film

INDOOR DISPLAY (COLD APPLICATION)

TOP : 75 mic PRONEX UV COLD Sand,Matt,SoftMatt

MEDIA : Off-set Prints, Inkjet or Electrostatic

BOTTOM : FOAMBOARD with Self-adhesive Layer or

Other Hard Mount Substrate

TOP & : FOAM POUCH with Photonex Hot or

BOTTOM PERFEX Gloss

MEDIA : Off-set Prints, Inkjet or Electrostatic

Suitable for making general display or with prints not

stuitable with use of cold laminating film.

INDOOR DISPLAY (HOT APPLICATION)

3 4

TOP : 150 mic CHROMONEX UV Sand, Matt, Gloss or

150 mic PERFEX UV Gloss

MEDIA : Inkjet Print on 175mic JETEL-BACK LIGHT media

Inkjet Print on 75mic JETVIN-WH/SA75(RM)

Suitable for ColorSpan, Encad, EPSON, HP prints

or other prints that doesn’t laminate with normal hot film

FLOOR GRAPHICS (COLD APPLICATION)

TOP :

200 micron PRONEX UV COLD

FLOOR MAT FILM (Orange peel Textured)

BOTTOM :

Inkjet Print on 75mic JETVIN-WH/SA75(RM) or

Inkjet Print on 75mic JETVIN-TR/SA75(RM)

STEP.1

STEP.2

In case of using EXCELJET inkjet media from GMP

TOP : 150 mic CHROMONEX UV Sand,Matt,Gloss or

75mic PRONEX UV COLD Film Sand,Matt,SoftMatt,Gloss

BOTTOM : Inkjet Print on 75mic JETEL-LIGHT PROTECT media

ROLL-UP DISPLAY

TOP : 150 mic CHROMONEX UV Sand,Matt,Gloss or

115 mic PHOTONEX UV Sand,Matt,Gloss or

75 mic PRONEX UV COLD Film Sand,Matt,SoftMatt,Gloss

BOTTOM : Inkjet Print on 175mic JETEL-BACK LIGHT media or

Inkjet Print on 75mic JETVIN-WH/SA75(RM)

OUT -DOOR DISPLAY

5 6

TOP : 150 mic CHROMONEX UV Sand,Matt,Gloss or

250 mic PERFEX Gloss, Matt or 75mic PRONEX UV

COLD Film Sand,Matt,SoftMatt,Gloss

BOTTOM : Inkjet Print on 200mic JETEL-LIGHT PROTECT media

Removable Paper Liner

POP -UP DISPLAY

TOP : 200 mic PRONEX UV COLD FLOOR MAT FILM

(Orange peel textured)

BOTTOM : Inkjet Print on 175mic JETVIN-WH/SA75(RM) or

Inkjet Print on 75mic JETVIN-TR/SA75(RM)

FLOOR GRAPHICS

TOP : 150 mic CHROMONEX UV Sand,Matt,Gloss or

115 mic PHONEX UV Sand, Matt, Gloss or

75mic PRONEX UV COLD Film Sand,Matt,SoftMatt,Gloss

32,75,125,250mic PERFEX Gloss and Matt Film

BOTTOM : Inkjet Print on 75mic,175mic JETEL-BACK LIGHT media or

Inkjet Print on 75mic,200mic JETEL-LIGHT PROTECT media

JETVIN-WH/SA75(RM) Media for Mount

IN-DOOR DISPLAY

We recommend where possible to use.

INKJET TIPS

Matts Papers

Glossy Papers

Hot process

Heat Activated Films

Cold Process

Pressure Setting Films

LEADERS IN LAMINATION TECHNOLOGY

Copyright GMP 2001. All rights reserved. Reproduction by any means of any image in this catalogue is prohibited without the prior consent of GMP and its authroized agent

Lamination Guide

for Graphic & Displays

This manual suits for next models

1

Table of contents

Other GMP Laminator manuals

GMP

GMP SURELAM-PRO540HR User manual

GMP

GMP SURELAM-PRO540HR User manual

GMP

GMP SURELAM-PRO540HR User manual

GMP

GMP EXCELMASTER-1600 User manual

GMP

GMP ELECTRO ULTRA LAMITRIM-1800 User manual

GMP

GMP PROTOPIC AUTO-540 HS User manual

GMP

GMP PROTOPIC-540 QUATRO SLIT User manual

GMP

GMP PROTOPIC AUTO-540 HS User manual

GMP

GMP QTOPIC-380 User manual

GMP

GMP EXCELAM-1100SWING User manual