GMP PROTOPIC AUTO-540 HS User manual

2015. 06

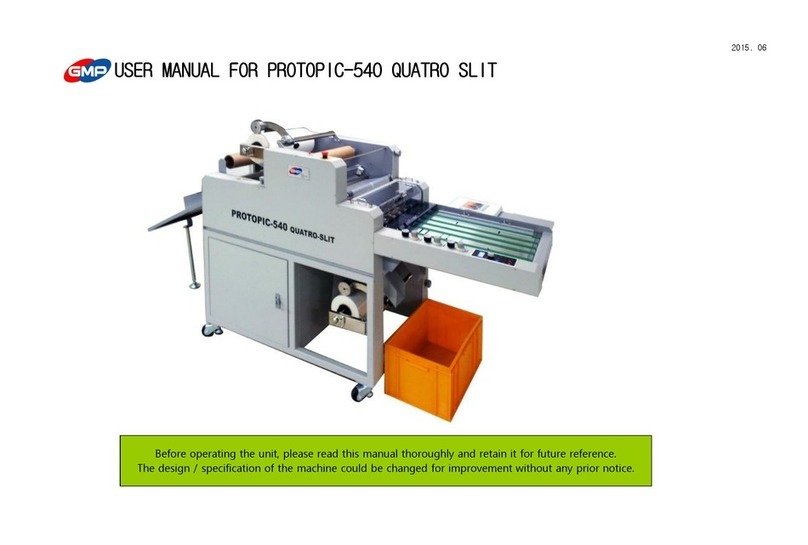

USER MANUAL FOR PROTOPIC AUTO-540 QUATRO SLIT

Before operating the unit, please read this manual thoroughly and retain it for future reference.

The design / specification of the machine could be changed for improvement without any prior notice.

INDEX

◐ SAFETY ◐ How to Laminate 37

page

Important Safety Instruction 3

page

Safety Device 6

page

◐ MAINTENANCE 43

page

Warning Stickers 7

page

◐ TROUBLESHOOTING 44

page

◐ INSTALLATION

Packing Contents 8

page

◐ SPECIFICATION 48

page

Main Devices 9

page

Move & Installation 10

page

◐ DIGITAL SLEEKING SOLUTION

Introduction of DIGITAL SLEEKING 49

page

◐ HOW TO USE CONTROL PANEL

GLOSS & MATT SLEEKING

50

page

Details for Display 13

page

HOLOGRAM SLEEKING 54

page

Control Panel 17

page

METALLIZE PRINTING 58

page

Messages 22

page

SLEEKING FILM SPECIFICATION 60

page

◐ HOW TO USE MAIN DEVICES

Feeding Devices 26

page

Lamination Devices 30

page

Cutting Devices

34

page

Other Devices 36

page

Important Safety Instruction

"Important Safety Instruction " is for the purpose of user's safety

and prevention of Property loss. Read thoroughly and Use rightly according to the manual

Warning : If you ignore this symbol, you could suffer serious injury or death

Caution: If you ignore this symbol, you could receive a serious injury or loss of property

This symbol means a prohibited action. If you ignore a prohibited action, you could suffer a personal injury and damage the machine

This symbol means a required action. If you don't follow this action, your safety is not guaranteed.

Required action will be included in this symbol.

Reference:The sign above refers the contents for user's safety and prevention of Property loss.

☞ POWER

Do not connect or disconnect with wet hands, as this will cause an electric shock

Do not overload a power supply,as this will cause a fire and an electric shock.

Do not use a damaged plug or lead, as this could cause a fire or an electric shock

Do not use other voltage and power supply other than specified, as this will cause a fire and an electric shock.

Warning

3/60

Important Safety Instruction

☞ POWER

Make sure plug is in the socket, as it could cause fire or an electric shock

For your safety, grounding the power

Do not pull the plug or bend improperly

Danger, Malfunction, loss of electricity could cause an electric shock

☞ Installation

Do not use materials near a naked flame

Do not use the machine in the sealed place.

Only use the specified power and voltage. It can be a reason of fireflame or an electricity fireflame.

Do not dissemble, make repairs or convert the machine. Contact your dealer for repairs

Ensure all hair, neckties, necklaces, are kept free of the feeding table to avoid injury

Do not convert the safety device and safety switch.

Do not spill any liquids on the laminator as this will cause damage and a possible electric shock

Do not use the flammable spray or flammable materials inside or outside the machine. As this could cause a fire.

Do not allow childern use of this equipment

Warning

Grounding

4/60

Important Safety Instruction

☞ POWER

When moving the product, turn off the power switch, disconnect the power plug from the socket

When lamintor is not in use, you must turn off the power switch, disconnect the power plug from the socket.

☞ Installation

anger - laminating blades are sharp and can cause injury.

More than 2 people are needed to carry this equipment to avoid personal injury or damage to the machine.

Keep gears and chains free of all materials

Do not touch the roller with your hand as you could be burnt.

Please avoid installing near the following places;

Gas stove, Ventilator or Air conditioner due the higher temperature or higher humidity

Do not place any materials on the laminator as they could catch a fire

Avoid the direct sunlight for the installing the machine

Avoid the dark and slope place for installation

Do not place any materials on the laminator as they could catch a fire

Do not touch the film and laminating machine just after lamination finishes as you could be burnt.

Use the machine with laminating purpose only.

Tidy up the place near the laminating machine.

Warning

5/60

Safety Device

☞ Emergency Switch

When emergency situation happened, it stops the running motor(rollers) rotation and system operation.

In case of emergency, use this switch.

☞ How to use

Press the Red button to operate the Emgency Stop Switch.

All system is stopped when this is pressed.

Turn the switch to the right to release from Emergency Status.

Emergency Switch

E-Stop S/W

6/60

WARNING STICKERS

For the user safety, in the outer design, the below sticker is attached. Be cautious not to injured during operation.

☞ Roller caution ☞ Higher Temperature

Do not touch the roller and heating plate with your hand as you could be burnt.

Do not touch on the heating part

Roller's higher temperature and press can damage your body

☞ Electricity Caution

☞ Cutting Caution

Inside the machine, high voltage flows,

Do not touch your body on the trimming device Do not open the outer case

You can suffer an injury You can suffer injury or sudden death with electricity shock

☞ Chain Caution

Do not your body wound into a chain.

You can suffer an injury

WARNING STICKERS

7/60

PACKING CONTENTS

Items Q'ty(EA)

LAMINATOR

1

FEEDING TABLE 1

PAPER GUIDE 2

AIR COMPRESSOR

1

AIR HOSE 1

GLASS TUBE FUSE (20mm) 250V/12.5A

4

GLASS TUBE FUSE (20mm) 250V/15A

2

WRENCH SET 1

LAMI TABLE

1

MANUAL 1

SEPARATOR IDLE ROLLER 1

LEADING PAPER

1

WASTE GUIDE 2

WASTE BASKET 1

`

CONTENTS

PROTOPIC AUTO-540 QUATRO SLIT

8/60

MAIN DEVICES

Main Devices

Decurling Adjustment Knob

Feeder

Roller Pressure

Gauge & Knob

Control Panel

Uppper Film Tension

Adjustmen Knob

Feeding Table

Lower Film Tension

Adjustment Knob

Side Slitter

Film Shaft Support

E-Stop S/W

Film Rewinder

Waste Guide

Waste Basket

Perforator

Perforator

9/60

UNPACK & MOVE

☞ Unpacking

1. Product is packed with vacuum aluminum packing materials to avoid corrosion and external packing is wooden crate.

2. Wooden crate can be disassembled by 11mm box spanner.

Disassemble the 5 panels on the left picture and remove vacuum packing materials. Then, move it to the installation place.

☞ Move the product

◑ In the following cases, it requires to move it by forklift.

1. If the ground is not level.

2. If it is required to be moved it to more than 10m distance.

3. After unpacking and move it to an installation area.

◑ If it requires to move it by caster wheel.

1. If a distance to move the laminator is less than 10m distance in the same area

2. Move the laminator gently with more than 4 persons at least. During it is moved,

grap each corner of the machine.

◑ After the machine is moved

1. Lock the caster wheel and fix the machine with height adjustment legs.

2. Plug the power cord and connect the air hose.

3. Check the machine as the test operation.

WARNING : Machine weight is very heavy, then be careful to move it to avoid damage / injury.

Before it is moved, power cord / air hose have to be unplugged / disconnected.

☞ Caster Wheel

Leveling foot is to fix / to level the machine.

After the machine is moved on the installation place, fix the machine with spanner.

UNPACK & MOVE

Caster Wheel

10/60

UNPACK & MOVE

☞ Circumstance

1. Be installed in the flat place.

2. If inflammable or combustible substance is around, it might be a reason for a fire.

3. Sufficient ventilation is required to omit the heat from the laminator while laminating.

4. Outlet should be near the machine, and easy to approach the outlet.

☞ Installation Space

* PROTOPIC AUTO-540 QUTRO SLIT

Product(WxLxH) 800 x 2,190x 1,320

Dimension(WxL) 1800*3670

※ The place for installation could be different depends on the job circumstance

☞ Power Connection

AC 220~240V/15A / Independent Power System.

WARNING : It must be grounded for safety.

Otherwise, this could be a cause of trouble and electric shock.

WARNING :Do not plug-in the laminator at a Outlet with the other devices,

this could be a cause of fire by overheating at outlet.

WARNING : Plug-in the laminator only at Outlet that is listed in the manual. Otherwise, this could be a cause of fire / electric shock.

WARNING : Insert the plug into the outlet exactly. Otherwise, this could be a cause of trouble of fire by overheating a outlet.

LAMINATOR

1320

2190

3670

1800

Grounding

Installation

11/60

UNPACK & MOVE

☞ How to connect

Compressed air needs to be supplied into the laminator to activate the bursting roller and pressure on the laminating roller.

WARNING : Plug in at Independent Power System (AC 220~240V).

Note : It is recommended to place the air compressor at outside of the laminator.

if you place inside of Lamitable, the high temperature could cause malfunction or trouble

☞ Maintenance of Compressor

A large amount of moisture is made during the air compressor is operated.

Then, the dry filter at output of compressor must be demoisturised once a day.

How to connect Air Compressor

Insert air hose in to the air

compressor

After Power On, pull the cap

upward.

Push the button as the arrow direction.

Laminater

Compressor

Example of Power

connection

Laminater

Compressor

12/60

HOW TO USE CONTROL PANEL

☞ Display Screen is composed of 3 kinds of screens, that is, Main Screen, Sub Screen 1 and Sub Screen 2.

☞ Main Screen : To check the main setting status in the laminator easily.

① "JOB:Poly-L" - for JOB Mode

To save values (temp. / speed for each films) that was set by operator.

This is composed of the below 13 kinds of modes.

JOBS

- Poly-L : Low Temp. operation for Polynex Film (set temp. 100℃) - MICRO : Job with Micronex Film (set temp. 120℃)

- Poly-H : High Temp. operation for Polynex Film (set temp. 120℃) - FOIL-L : Low Temp. operation for Metallic Foil (set temp. 115℃)

- Nylon : Job with Nylonex Film (set temp. 130℃) - FOIL-H : High Temp. operation for Metallic Foil (set temp. 125℃)

- PET-L : Low Temp. operation for Perfex Film (set temp. 90℃) - User-1 : Setting Job by operator 1

- PET_H : High Temp. operation for Perfex Film (set temp. 110℃) - User-2 : Setting Job by operator 2

- FUS-L : Low Temp. operation for Fusing(Sleeking) Film (set temp. 125℃) - User-3 : Setting Job by operator 3

- FUS_H : Hight Temp. operation for Fusing(Sleeking) Film (set temp. 135℃)

NOTE : Refer to the "JOB" button functionality to check / save setting values.

Details for Display

1

2

3

4

5

6

7

13/60

HOW TO USE CONTROL PANEL

② "T: 000℃ / 029℃" "B: 000℃ / 018℃" - for display of Temp. & Jobs

To display Setting / Current Temp. of Laminating Roller and Job Availability. Setting Temp. Range is "0~150℃".

'000' is Setting Temperature. '029' is Measure Temperature.

If the both temperature will becomes same, you can start lamination work.

NOTE : Refer to "Buttons" functionality for how to set temp.

③ "BURST" - for display of substrate cutting size

To display operation time for bursting roller. Setting Bursting Point Range is Min. "960"~ Max. "1060".

Recommendable Setting Value is 1000.

NOTE : Refer to "Buttons" functionality for how to set bursting time.

④ "SPEED" - for display of roller speed

To display rotation speed of laminating roller. Speed setting range is Min. "1" ~ Max. "15".

NOTE : Start at low speed for initial stage of job.

⑤ "LENGTH" - for display of substrate length

Displayed value means substrate length. Setting value of substrate length is a required length for lamination.

Setting substrate length range is 250~800mm.

참고 : Refer to "Buttons" functionality for how to set substrate length.

⑥ "FWD OFF" - for display of status for LAMINATOR MAIN MOTOR.

- FWD OFF : Forward Operation is stopped. - FWD ON : Forward Operation is being processed.

⑦ "C:00055" - for display of daily lamination q'ty

To display q'ty of laminated results for a certain period. It can be reset if it is required.

NOTE : Refer to "Button" functionality for how to reset counter.

14/60

HOW TO USE CONTROL PANEL

☞ Sub-Screen 1 : To check cylinders & motors operation status manually.

① PRESS : Display operation status of MAIN ROLLER.

Press SPEED button to operate it manually.

② STOPPER : Display operation status of STOPPER.

Press MAIN SCREEN MODE button to operate it manually.

③ BURST : Display operation status of BURST. Press JOB button to operate it manually.

④ SHUTTER : Display operation status of SHUTTER. Press TABLE UP button to operate it manually.

⑤ WHEEL : Display operation status of WHEEL. Press TABLE DOWN button to operate it manually.

⑥ FD : Display operation status of FEEDER MOTOR. Press MANUAL RUN button to operate it manually and speed also can be adjusted.

⑦ BT : Display operation status of BURST MOTOR. Press BURST POSITION button to operate it manually.

DUAL(SINGLE) : Display heater control status.

In case of 'DUAL', heating of top and bottom roller is available. But in case of 'SINGLE', only top heating is available.

⑧ TC : Display TOTAL COUNTER.

1

2

3

4

5

6

7

8

15/60

HOW TO USE CONTROL PANEL

☞ Sub-Screen 2: Display operation status of SWITCH & SENEOR

① PILE : Display operation status of PAPER PILE DETECT MICRO SWITCH.

② HOME : Display operation status of FEEDER HOME SENEOR.

③ T-UP & T-DN : Display operation status of TABLE UP & DOWN LIMIT SWITCH.

④ NORMAL STATUS! : If an error is occurred, message would be displayed.

⑤ EMS : Display operation status of EMERGENCY SWITCH.

⑥ SO : Display operation status of MIS-FEEDING SENSOR OFF.

Press MANUAL RUN button to operate MISFEEDING SENSOR manually.

- SO(SENSOR OFF) ON status : if the SENSOR detect, system is not stopped.

- SO(SENSOR OFF) OFF status : if the SENSOR detect, system is stopped.

⑦ MSN : Display status of missfeeding sensor.

'O' means the status that missfeeding sensor being detected

'X' means the status that missfeeding sensor not being detected

⑧ LSN : Display status of Loading sensor that located 80mm away from misfeed sensor to table side.

'O' means the status that loading sensor being detected

'X' means the status that loading sensor not being detected

⑨ ISP : Display current Motor Speed.

1

2

3

4

5

6

7

8

9

16/60

HOW TO USE CONTROL PANEL

"SPEED"

To adjust setting value of laminating speed.

Speed Setting Range is Min. "1" ~ Max. "15".

To set up laminating speed.

Speed Setting : Press SPEED button and adjust speed with UP / DOWN buttons.

NOTE : Lamination q'ty is increased in proportion to increase of setting speed.

"PAPER LENGTH"

To set up substrate length.

Substrate Length Setting Range is Min. "250" ~ Max. "800".

NOTE : How to set substrate length is the same as how to set speed in "SPEED" menu.

It saves automatically 5 seconds after set up.

NOTE : The laminator has Underlap Cutting system. Then, setting value has to be shorter than substrate by 3~5mm.

"JOB"

To change JOBs.

There are 13 kinds of JOBs and temp. and substrate length for each mode can be saved separately.

NOTE : How to set substrate Burst Posion is the same as how to set speed in "SPEED" menu.

It saves automatically 5 seconds after set up.

CONTROL PANEL

17/60

HOW TO USE CONTROL PANEL

"BURST POSITION"

To change Bursting Position.

Bursting Position Setting Range is Min. "580" ~ Max. "660".

NOTE : How to set substrate length is the same as how to set speed in "SPEED" menu.

It saves automatically 5 seconds after set up.

"TEMP"

To adjust temperature on TOP ROLLER.

Temp. Adjustment Range is Min. "0" ~ Max. "150".

While the system is stopped, if the TEMP BUTTON is pressed for more than 3 seconds, DAILY COUNTER is reset.

When the LED is on, top temp. control is available.

On status of LED ON, if temp. button is pressed, you can control bottom temperature.

NOTE : How to set substrate Temp is the same as how to set speed in "SPEED" menu.

"BURST ON/OFF"

To operate / stop Bursting.

If the button is pressed during lamination, Bursting is ON(operation) and bursting roller starts to move up/downwards.

If the button is pressed again, it turns to stop(OFF) and bursting roller is stopped.

NOTE : If the system is in stop status, the button is not activated. Then, the button can be activated only

in system operation status.

18/60

HOW TO USE CONTROL PANEL

"BURST H/L SPEED"

To increase the burst motor speed by 20% faster.

If the button is pressed : MOTOR HIGH SPEED

If the button is not pressed : MOTOR LOW SPEED

While the system is stopped, if the BRST H/L BUTTON is pressed for more than 5 seconds, heating mode is changed.

NOTE : Apply the above condition to laminate "NYLONEX(Nylon base)","PERFEX(PET base)" films.

"TABLE(UP/DOWN)"

To make the Feeding Table "UP" or "DOWN".

If the "DOWN" is selected, the feeding table goes down and while the "UP" is pressed, the feeding table goes up.

NOTE : While the "UP" is pressed, the feeding table is operated and the button is not pressed,

the operation is stooped.

NOTE : If the Feeder would not be at the Ready position, the feeding table cannot go upside.

-> Select the "FEEDER HOME" and take the Feeder at "Origin" Position.

"TABLE STOP"

To stop table motor.

19/60

HOW TO USE CONTROL PANEL

MANUAL RUN

To operate / stop VACUUM PUMP.

Press the button to operate (ON) the Vacuum Pump.

Press the button again to stop (OFF) the Vacuum Pump.

In normal lamination status, if the lamination is stopped, the vacuum pump is in operation (ON) status and

if it is pressed again, it turns to stop the Vacuum Pump.

"FEEDER HOME"

To place the Feeder Motor at Origin Point.

※ Feeder Origin Point

Initial Stage of the feeder to feed substrate.

"JOG"

To operate the Main Motor manually.

NOTE : Press JOG button to operate the Main Motor at setting speed.

"SCREEN CONV"

To change LCD screen mode.

20/60

Other manuals for PROTOPIC AUTO-540 HS

1

Table of contents

Other GMP Laminator manuals

GMP

GMP SURELAM-PRO540HR User manual

GMP

GMP RTR-380COMBI User manual

GMP

GMP GraphicMaster 1600HR User manual

GMP

GMP EXCELAM-1100SWING User manual

GMP

GMP PROTOPIC AUTO-540 HS User manual

GMP

GMP QTOPIC-380 User manual

GMP

GMP PROTOPIC-540 QUATRO SLIT User manual

GMP

GMP EXCELMASTER-1600 User manual

GMP

GMP SURELAM-PRO540HR User manual

GMP

GMP SURELAM-PRO540HR User manual

Popular Laminator manuals by other brands

MIMO

MIMO stamping 2 owner's manual

UNITED OFFICE

UNITED OFFICE ULGD 350 A1 operating instructions

Banner

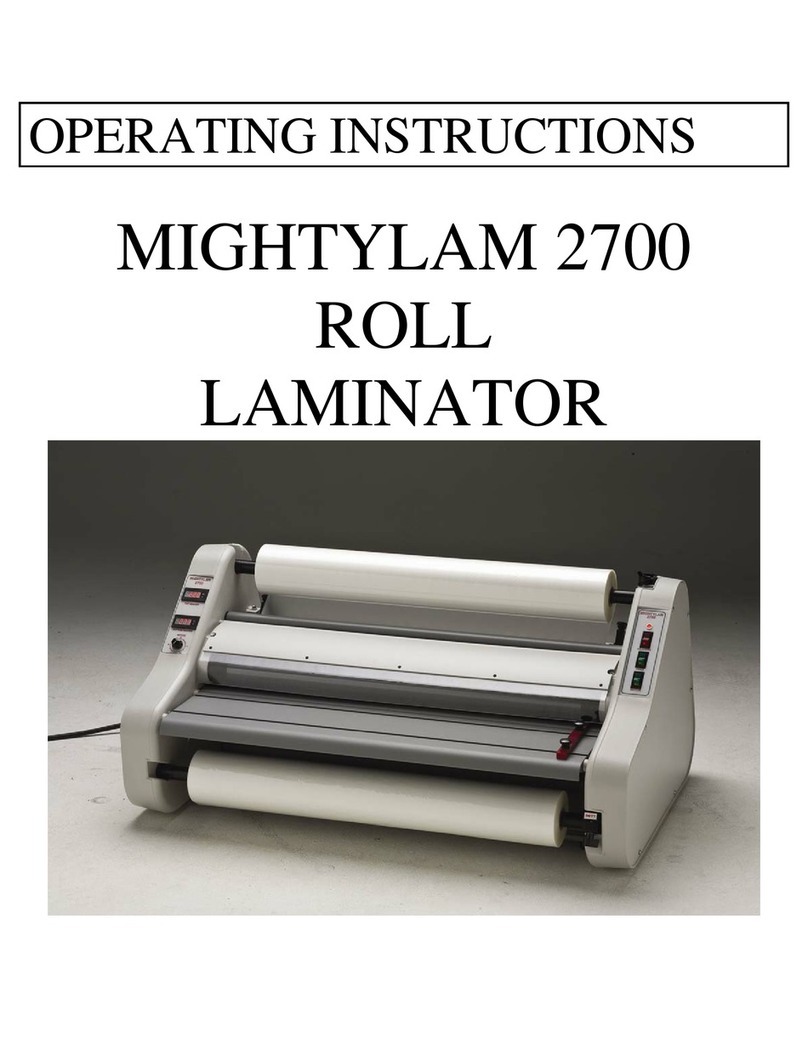

Banner MIGHTYLAM 2700 operating instructions

Tamerica

Tamerica TCC-2700 operating instructions

Martin Yale

Martin Yale MyBinding papermonster LA4 operating instructions

Xyron

Xyron Xyron ezLaminator quick guide