0GENERALSECTION 5

0.1 INTRODUCTIONINFORMATIONS 5

0.1.1DEFINITIONS 5

0.1.2TERMSAND SYMBOLSUSED 5

0.1.3RULES REFERENCE 5

0.2 DOCUMENTS RELATEDWITHINSTALLATION 5

0.3 SAFETYPRECAUTIONDURINGINSTALLATION 5

0.4 TOOLING 5

0.5 GENERALORDERS 6

1FEATURES AND REQUIREMENTS 7

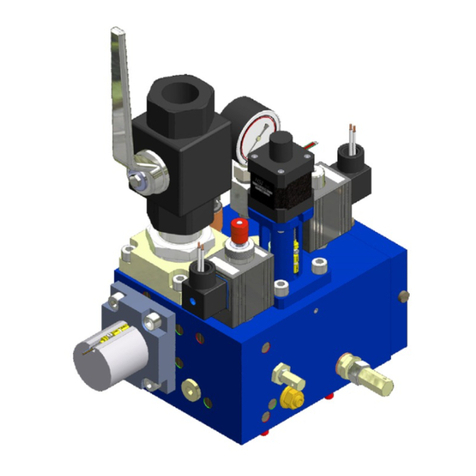

1.1 THE NGVA3 VALVE 7

1.2 THE FLUID 7

1.3 HOWTHE NGVA3 WORKS 8

1.4 THE DOUBLE SAFETY 9

1.5 MAIN FEATURES 9

2INSTALLATIONOPERATIONS 10

2.1 HYDRAULICCONNECTIONS 10

2.1.1MINIMUMDIMENSIONSAND HOLES FOR POWER UNIT 10

2.1.2INPUTAND OUTPUT -POWER UNITSIDE 11

2.2 HYDRAULICCIRCUIT 11

2.3 ELECTRICALCONNECTIONS 12

2.3.1CONTROLPANELREQUIREMENTS 12

2.3.2INTERVENTION TIME 12

2.3.3 FAULT SCHEMAS 13

2.4 OPERATIONS PRELIMINARYTOCONNECTION 13

2.5 SCHEMAS OF THE CONNECTIONS TOCONTROL PANELS 14

2.5.1MAIN SCHEMA 14

2.5.2CONNECTION SCHEMAS FOR SIGNALS 15

2.5.3CONNECTION SCHEMAS FOR POWER 15

2.6 CONNECTIONS TOTHE TERMINAL 16

2.7 CONNECTIONS TOTHE CARD 16

2.8 CONNECTIONOF HYDRAULICPIPES 17

2.8.1CONNECTION WITH FLEXIBLEHOSE 17

2.8.2CONNECTION WITH ARIGID PIPE 17

3NGVA3CONTROLBOARD 18

3.1 ELECTRICALFEATURES 18

3.2 PERFORMANCES 18

3.2.1SIGNALLERS 18

3.3 CONNECTIONS 19

3.3.1CONTROLPANELINTERFACE 19

3.3.2VALVE INTERFACE 20

3.3.3USER INTERFACE 21

3.4 SIGNALS AND COMMANDS SEQUENCE 22

3.4.1UPWARD DIAGRAM 22

3.4.2DOWNWARD DIAGRAM 23

3.5 DECELERATIONDISTANCES 24

4ADJUSTMENTSAND TEST 25

4.1 ADJUSTMENTOF THE OVERPRESSURE VALVE (OPP/MPS) 25

4.2 RAMPRESSURE ONTHE VSMA ADJUSTMENT 26

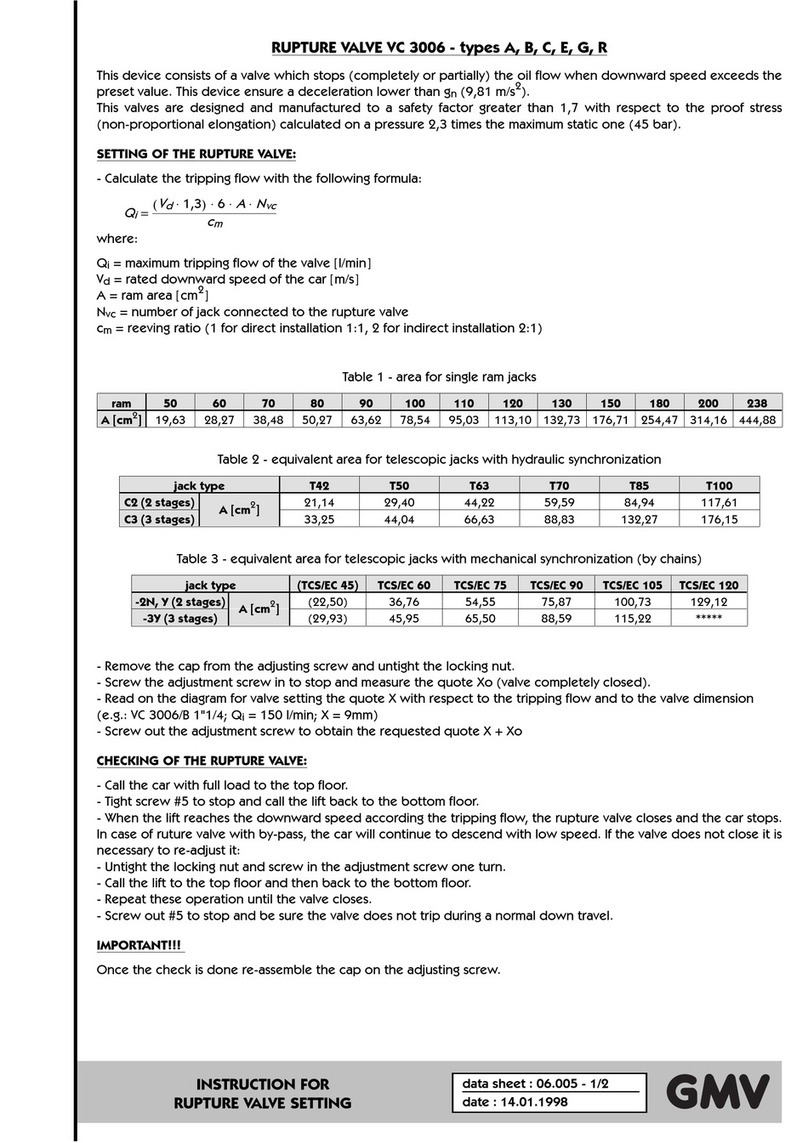

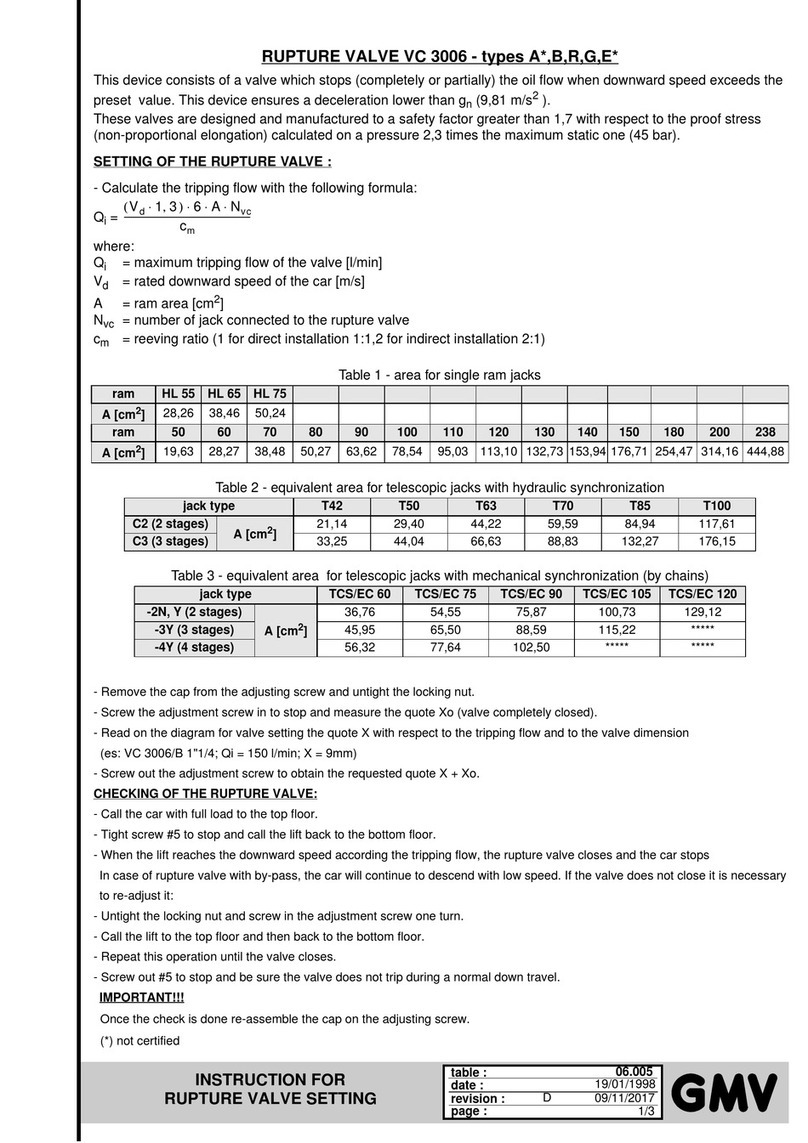

4.3 PIPE RUPTURE VALVE (VC) TEST 26

4.4 TESTOF DEVICES THATPREVENTUNCONTROLLEDMOVEMENT 26

4.4.1PREREQISITES 26

0.1.1 26

4.4.2TESTIN UPDIRECTION 27

4.4.3TESTIN DOWN DIRECTION 27

4.5 TESTOF THE DOUBLE SAFETYSYSTEM 28

4.5.1SIMULATION OFTHE VRP FAULT 28

4.5.2SIMULATION OFTHE VB FAULT 29

4.5.3TEST OFTHEMONITORING SYSTEM 29

4.6 FAULTSIMULATIONONOUTPUT RDY AND RUN 30

4.6.1TESTRUN ALWAYS ON 30