SoliTek SOLID User manual

1

Version: 21 06

SoliTek

SOLID

INSTALLATION MANUAL

Valid for:

SOLID Pro M.60, BLACKSTAR (SOLID Framed) B(M).60, SOLID Bifacial B.60

2

Table of contents

1

General requirements .................................................................................................................... 4

2

Handling .......................................................................................................................................... 5

3

Application ...................................................................................................................................... 6

3.1

Restrictions ................................................................................................................................. 6

3.2

Recommendations ...................................................................................................................... 6

4

Electrical installation ....................................................................................................................... 7

4.1

Safety .......................................................................................................................................... 7

4.2

Configuration .............................................................................................................................. 9

4.3

Overcurrent protection device (OCPD) ..................................................................................... 10

4.4

Cable & wiring ........................................................................................................................... 10

4.5

Grounding ................................................................................................................................. 11

4.5.1 SOLID Framed series modules grounding .................................................................................. 11

4.5.2 SOLID Pro and bifacial series grounding .................................................................................... 12

4.6

Connectors ................................................................................................................................ 12

4.7

Bypass diodes ............................................................................................................................ 12

5

Fire class rating ............................................................................................................................. 13

6

Mechanical mounting ................................................................................................................... 13

6.1

Mounting rails ........................................................................................................................... 13

6.2

Mounting with clamps .............................................................................................................. 14

6.3

SOLID Pro P(M).60 and Bifacial B.60 mounting ........................................................................ 16

6.3.1 Transversal rails ......................................................................................................................... 16

6.4

BLACKSTAR (SOLID Framed) B(M).60mounting ........................................................................ 18

6.4.1 Mounting with clamps ............................................................................................................... 18

3

6.4.2 Mounting with bolts .................................................................................................................. 18

7

Maintenance ................................................................................................................................. 19

8

Specifications ................................................................................................................................ 20

9

Disclaimer of liability .................................................................................................................... 21

4

1 General requirements

Thank you for choosing SoliTek panels!

Please read this guide in it’s entirely before the installation.

The purpose of this document is to provide minimum requirements and recommendations for safe

and successful installation of SoliTek PV modules.

This document also contains requirements necessary to retain SoliTek PV module compliance with

IEC 61215 and IEC 61730 standards.

This guide contains basic information regarding JSC “SoliTek Cells” SOLID series photovoltaic

modules, their installation and safe handling. All instructions should be read and understood before

attempting installation. If there are any questions, please contact your dealer or JSC “SoliTek Cells”

for further information.

This documentation refers to the PV-modules themselves and is not meant to be a complete

installation manual for personnel not specifically trained to PV-modules. It serves as a general but

strictly mandatory to the Installer reference. Infringement or inaccurate observance of any clause of

this documentation voids the warranty.

The installer must understand and follow all applicable local, state, and federal regulations and

standards for building construction, electrical design, fire, and safety, and must check with local

authorities to determine applicable permitting requirements before attempting to install or maintain

PV modules and should become familiar with the mechanical and electrical requirements for

photovoltaic systems.

Failure of follow instructions in this guide may damage system components, endanger personnel,

damage property, or invalidate the panel warranty.

5

Rooftop PV systems should only be installed on dwellings that have been formally analyzed for

structural integrity, and confirmed to be capable of handling the additional weighted load of PV

system components, including PV modules, by a certified building specialist or engineer.

For your safety, do not attempt to work on a rooftop until safety precautions have been identified

and taken, including without limitation fall protection measures, ladders or stairways, and personal

protective equipment (PPE).

For your safety, do not install or handle PV modules under adverse conditions, including without

limitation strong or gusty winds, and wet or frosted roof surfaces.

The flat-plate PV module construction consists of a laminated assembly of solar cells encapsulated

within an insulating material within two glass sheets.

Keep this documentation in a safe place for future reference.

Do not attempt to disassemble the module, and do not remove any attached nameplates or

components! Doing so will void the warranty.

2 Handling

SoliTek PV modules must be transported in the supplied packaging only and kept in the packaging

until they are ready to be installed. Protect pallets against movement and exposure to damage during

transportation. Secure pallets from falling over. Do not exceed the maximum height of pallets to be

stacked, as indicated on the pallet packaging. Store pallets in a cool and dry location until the PV

modules are ready to be unpackaged.

SoliTek PV modules are heavy and should be handled with care. Never use the junction box or cables

as a grip. Do not exert mechanical stress on the cables. Never step on PV modules or drop or place

heavy objects on them. Be careful when placing PV modules on hard surfaces and secure them from

falling. Broken glass can result in personal injury. PV modules with broken glass cannot be repaired

and must not be used. Broken or damaged PV modules must be handled carefully and disposed of

properly.

6

3 Application

3.1 Restrictions

SoliTek PV modules must be mounted on appropriate mounting structures positioned on suitable

buildings, the ground, or other structures suitable for PV modules (e.g. carports, building facades or

PV trackers). PV modules must not be mounted on moving vehicles of any kind. Modules must not

be installed in locations where they could be submerged in water.

Artificially concentrated light must not be directed on SoliTek PV modules.

3.2 Recommendations

SoliTek recommends that PV modules be mounted at a minimum tilt angle of 10 degrees to allow for

proper self-cleaning from rain.

Partial or complete shading of a PV module or modules can significantly reduce system performance.

SoliTek recommends minimizing the amount of shade throughout the year to increase the amount

of energy produced by the PV modules.

High system voltages could be induced in the event of an indirect lightning strike, which could cause

damage to PV system components. The open area of wire loops should be minimized; in order to

reduce the risk of lightning induced voltage surges.

Better module ventilation and shorter connection cables increase electrical energy production.

For bifacial modules:

It is recommended to increase PV panel height from the ground so that more light can travel beneath

the module and then reflect

The bifacial gain increases significantly if modules are installed above white (high albedo value), light

reflecting surfaces.

7

4 Electrical installation

4.1 Safety

PV modules can produce current and voltage when exposed to light of any intensity. Electrical current

increases with higher light intensity. DC voltage of 50 Volts or higher is potentially lethal. Contacting

the live circuitry of a PV system operating under light can result in lethal electric shock.

De-energize PV modules by removing them entirely from light or by covering their front surface with

an opaque material. Regard the safety regulations for live electrical equipment when working with

modules that are exposed to any light. Use insulated tools and do not wear metallic jewelry while

working with PV modules.

In order to avoid arcing and electrical shock, do not disconnect electrical connections under load.

Faulty connections can also result in arcing and electrical shock. Keep connectors dry and clean, and

ensure that they are in proper working condition. Never insert metallic objects into the connectors,

or modify them in any way in order to secure an electrical connection.

Do not touch or handle PV modules with broken glass unless the PV modules are first disconnected

and you are wearing proper PPE. Avoid handling PV modules when they are wet unless cleaning the

PV modules as directed in this manual. Never touch electrical connections that are wet without

protecting yourself with insulated gloves.

The modules are qualified for application class A: Hazardous voltage (IEC 61730: higher than 50V DC;

EN 61730: higher than 120V), hazardous power applications (higher than 240W) where general

contact access is anticipated.

Installing solar photovoltaic systems requires specialized skills and knowledge. It should be

performed only by qualified and specially instructed personnel. The installer assumes all risk of injury,

including risk of electric shock.

Use only equipment, connectors, wiring and mounting hardware specifically designed for use in a

photovoltaic system.

8

Before any manipulation at an installed PV plant, switch it of first on AC-side after on DC-side of the

inverter or the charge controller.

When disconnecting wires connected to a photovoltaic module that is exposed to light, an electric

arc may occur. Arcs can cause burns, start fires or otherwise create safety (up to lethal electric shock)

problems.

Check for remaining voltage before starting and observe the local safety relevant regulations for such

working conditions.

Under normal conditions, a photovoltaic module can produce more current and/or voltage (here:

30V DC) than reported at standard test conditions.

Contact with a DC voltage of 30 V or more is potentially hazardous. Exercise caution when wiring or

handling modules exposed to sunlight.

Only connect modules with the same rated output current in series. If modules are connected in

series, the total voltage is equal to the sum of the individual module voltages.

Only connect modules or series combinations of modules with the same voltage in parallel. If

modules are connected in parallel, the total current is equal to the sum of individual module or series

combination currents.

Always use the same type of module within a particular photovoltaic system.

If the sum of short circuit currents of the parallel connected modules passes over the reverse current

string diodes or fuses have to be used in each string of modules connected in parallel. These string

diodes or fuses have to be qualified for the maximum expected current and voltage. The fuse rating

value is also corresponding to the maximum reverse current that a module can withstand. The

reverse current value can be found on the product label, in the product datasheet or chapter 9 of

installation manual. Observe the instructions and safety precautions for all other components used

in the system, including wiring and cables, connectors, DC-breakers, inverters, etc.

9

Use appropriate safety equipment (insulated tools, dielectric gloves and shoes, etc) approved for use

on electrical installations.

4.2 Configuration

Under normal conditions, a photovoltaic module is likely to experience conditions that produce more

current and/or voltage than reported at Standard Test Conditions (STC: 1000 W/m2, AM 1.5, and 25°C

cell temperature) or Bifacial Standard Test Conditions (BSTC: 1167 W/m2, AM 1.5, and 25°C cell

temperature). The short-circuit current (ISC) should be multiplied by a factor of 1.25 and the open-

circuit voltage (VOC) should be multiplied by a factor of up to 1.25 based on the lowest and highest

ambient temperature recorded for the installation location when determining component voltage

ratings, conductor current ratings, fuse sizes, and size of controls connected to the PV output.

Voltages are additive when PV modules are connected directly in series, and module currents are

additive when PV modules are connected directly in parallel. PV modules with different electrical

characteristics must not be connected directly in series. The use of suitable third-party electronic

devices connected to PV modules may enable different electrical connections and must be installed

according to the manufacturer’s specified instructions.

The maximum voltage of serial interconnection of the modules must be less than the maximum

certified module‘s system voltage. Also, the maximum input voltage of the inverter and of the other

electrical devices in the system must be taken into account. The open circuit voltage of the array

string needs to be calculated at the lowest expected ambient temperature for the location. The

maximal system voltage for module is indicated in the modules datasheet.

Accordingly for Pro or Bifacial series modules, the values of ISC and VOC under STC or BSTC marked

on this module should be multiplied by a factor of 1,25 when determining component voltage ratings,

conductor current ratings, fuse sizes, and size of controls connected to the PV output. In the USA,

refer to Section 690-8 of the National Electrical Code (NEC) for an additional multiplying factor of 125

percent (80 percent de-rating) which may be applicable.

10

4.3 Overcurrent protection device (OCPD)

When the potential reverse current of a PV string exceeds the rated SoliTek PV module series fuse

rating (values indicated at the module datasheet) an overcurrent protection device (OCPD) must be

used (IEC 61730-1 clause 12.3). An overcurrent protection device is required for each series string if

more than two series are connected in parallel. In this case, it is needed to use one fuse per string

rated at 1.25 x Isc or higher (Isc is the PV module’s short circuit current at STC). A PV fuse on each PV

string will protect the PV modules and conductors from overcurrent faults and help minimize any

safety hazards. The PV fuse will also isolate the faulted PV string so the balance of the PV system can

continue to generate electricity.

Fuse amp rating ≥ 1.25 x Isc

Select next higher standard rating at the catalogue of available PV Fuses.

Isc = Short-circuit current of one module at Standard Test Conditions (STC);

Considering the values of Isc of SoliTek modules, the right value of the PV Fuses to be used at the

installation is 20 A. SoliTek recommends using PV fuses in both the positive and negative conductors.

4.4 Cable & wiring

SoliTek PV modules are provided with two standard, sunlight resistant output cables that are

terminated with PV connectors ready for most installations. The positive (+) terminal has a male

connector while the negative (-) terminal has a female connector. The module wiring is intended for

series connections [i.e. male (+) to female (-) interconnections], but can also be used to connect

suitable third-party electrical devices that may have alternative wiring configurations so long as the

manufacturer’s instructions are followed.

Use field wiring with suitable cross-sectional areas that are approved for use at the maximum short-

circuit current of the PV module. All wiring must be double insulated, cross-linked cables with a

minimum rating of 1,8 kV (over 1500 V voltage) and minimum rated temperature of 90 ˚C. Wire size

11

not less than 4 mm². The insulation type should be appropriate for the type of installation method

used and must meet IEC 61730 and Safety Class II requirements.

Insulation level: 1,8 kV (conductor-conductor);

Temperature: -40°C up to +90°C at least;

Construction of conductor: tinned stranded copper wire with copper purity greater than 99,9%;

Primary insulation: cross-linked polyethylene (XLPE), sunlight and moisture resistant, flame

retardant. Suitable for conduit and raceways installed underground;

Insulation (jacket): thermoplastic, sunlight resistant, flame retardant, water resistant.

Minimum cable outer diameter with insulation – 5,2 mm.

Minimum conductor cross-section – 4 mm².

SoliTek recommends installers use only sunlight resistant cables qualified for direct current (DC)

wiring in PV systems. Cables should be fixed to the mounting structure in such a way that mechanical

damage of the cable and/or the module is avoided. Do not apply stress to the cables. For fixing, use

appropriate means, such as sunlight resistant cable ties and/or wire management clips. While the

cables are sunlight resistant and waterproof, where possible, avoid direct sunlight exposure and

water immersion of the cables.

Standard length of cables from the junction boxes is 1,2 m. It is intended that two panels would

interconnect in the system.

4.5 Grounding

Functional grounding is not foreseen for SOLID modules. If it is performed, local electric codes and

regulations must be observed and used grounding means have to be isolated from live parts by

reinforced insulation. Safety grounding must be performed accordingly.

4.5.1 SOLID Framed series modules grounding

For SOLID Framed series of PV panels grounding has to be assured by connecting module frame to

the grounding structure. Observe all local electric codes and regulations. A bolted connection is

required, it incorporates:

12

A screw size of M4 or greater;

A star washer under the screw head or a serrated screw must penetrate nonconductive

coatings like anodized frame;

Screw and star washer has to be made of stainless steel;

Grounding screw has to go through all the connecting elements and protrude outside by two

threads.

Devices listed and identified for grounding metallic frames of PV modules are permitted to ground

the exposed metallic frames of the module to grounded mounting structures.

In any case the grounding screws or other parts have to be used separately from mounting parts of

the module.

Grounding resistance of grounding structure shall be reached according to local regulations,

Eurocodes or other legal normative references.

4.5.2 SOLID Pro and bifacial series grounding

Due to that SoliTek SOLID Pro and Bifacial modules are frameless, no module grounding is required.

Other PV plant equipment should be grounded according to the local and national electrical codes.

4.6 Connectors

Connectors for SoliTek PV panels are MC4 compatible. Keep MC4 compatible connectors dry and

clean, and ensure that connector caps are hand tight before connecting the modules. Do not attempt

making an electrical connection with wet, soiled, or otherwise faulty connectors. Avoid sunlight

exposure and water immersion of the connectors. Avoid connectors resting on the ground or roof

surface. Do not disconnect under load. Faulty connections can result in arcs and electrical shock.

Check that all electrical connections are securely fastened. Make sure that all locking connectors are

fully engaged and locked.

4.7 Bypass diodes

The PV module’s junction box contains 3 bypass diodes (one in each part of split junction box;

Schottky type) connected in parallel with the PV cell strings. In the case of partial shading (hot-spot

13

effect), the diodes bypass the current generated by the non-shaded cells, thereby limiting module

heating and performance losses.

Bypass diodes are not overcurrent protection devices. Bypass diodes divert current from the cell

strings in the event of partial shading. The characteristics of these diodes:

Voltage rating – 50 V;

Current rating – 20 A.

5 Fire class rating

SoliTek SOLID module has been approved by the IEC fire test and achieved Flammability Class A. Fire

test was performed at the inclination of 127 mm per 300 mm (as prescribed in the point A.2.5 of IEC

61730-2).

6 Mechanical mounting

All mechanical pressure values indicated in this manual are design figures, this means that test values

are 1,5 times greater, for instance if the modules are declared to withstand 1600 Pa pressure, it

means they were tested at 2400 Pa pressure.

6.1 Mounting rails

Please observe the safety regulations and installation instructions included with the mounting rail. If

necessary please contact the supplier directly for further information.

The modules must be safely set onto the mounting rail. The whole rail supporting the photovoltaic

system must be strong enough to resist potential mechanical pressures caused either by wind or

snow, in accordance with local, regional and state safety (and other associated) standards.

Make sure that the mounting rail will not deform or affect the modules when it expands as a result

of thermal expansion.

14

The mounting rail must be made of durable, anti-corrosive and UV-resistant materials.

6.2 Mounting with clamps

SoliTek has tested its modules with Alumero CLICK 6.8 clamps. Use at minimum 4 clamps to fix

modules on the mounting rails. Modules clamps metal parts should not come into contact with the

front or back glass. When choosing this type of clamp-mounting method, use at least four clamps on

each module; two clamps should be attached on each long side. Depending on local wind and snow

loads, additional clamps may be required to ensure that modules can bear the load.

Applied torque should refer to mechanical design standard according to the bolt customer is using.

It is recommended to use only certificated equipment for the PV plant installation.

Alumero CLICK 6.8 clamps tightening torque should be at least 15 Nm, but not greater than 20 Nm.

Usually 15 Nm is reached when two aluminum profiles touch each other. When using other mounting

clamps please refer to manufacturers recommendations.

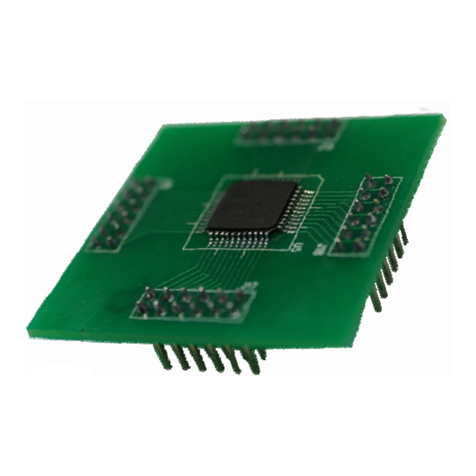

Table 1. Laminated, CLICK 6.8 type, clamp details

Product Visualization Length options: Material / surface

Laminate

middle

clamp

CLICK 6.8

1. 150mm

2. 200mm

EN AW 6063/ T66;

EPDM; mill finish / black

Laminate

end clamp

CLICK 6.8

1. 150mm

2. 200mm

EN AW 6063/ T66;

EPDM; mill finish / black

15

Figure 1. Recommended clamp dimensions for the SoliTek PV Glass-Glass modules

16

6.3 SOLID Pro P(M).60 and Bifacial B.60 mounting

6.3.1 Transversal rails

• 1600 Pa wind load / 1600 Pa snow load • 1600 Pa wind load / 3600 Pa snow load

Figure 2. 6.3 SOLID Pro P(M).60 mounting with four fixing points and transversal rails.

Using four fixing points with clamps on 60 cell regular size modules allows to achieve 1600 Pa of wind

loadings and 3600 Pa of snow loads if Alumero CLICK 6.8 200 mm clamps are used. If 100 mm clamps

are used 1600 Pa of wind and snow loads can be achieved. Using four fixing points with 100 m length

clamps in portrait configuration is not recommended due to risk of panels sliding out of clamp

gaskets. It is normal that at loadings higher than 1600 Pa panels will touch the transversal rails. Please

make sure that the rail surface is smooth, because even the smallest sharp edge can cause fast

mechanical failure. If the rail surface is not smooth, sharp edges occur, it is recommended to use rail

gaskets to even the touching surface.

17

• 1600 Pa wind load / 5330 Pa snow load

Figure 3. SOLID Pro P(M).60 and Bifacial B.60 mounting with eight fixing points and transversal rails.

Using four Alumero CLICK 6.8 200 mm clamps allows for the panel to achieve 5330 Pa of snow loads

and 1600 Pa of wind loads.

It is normal that at loadings higher than 1600 Pa panels will touch the transversal rails. Please make

sure that the rail surface is smooth, because even the smallest sharp edge can cause fast mechanical

failure. If the rail surface is not smooth, sharp edges occur, it is recommended to use rail gaskets to

even the touching surface.

18

6.4 BLACKSTAR (SOLID Framed) B(M).60mounting

6.4.1 Mounting with clamps

Clamping on the long side of module frame allows for the panel to withstand 3600 Pa of snow load

and 1600 Pa of wind loads.

Figure 4. SOLID Framed P(M).60 mounting with clamps

6.4.2 Mounting with bolts

The module must be attached and supported by four M8 stainless steel bolts through the indicated

mounting holes (Figure 1) on the transversal bars. Torque on the clamp bolt has to be in range of 8-

10 Nm. Transversal bars positioning is shown in Figure 11, 6.6.1. section.

If additional mounting points are required depending on the local wind and snow loads then

mounting solution with clamping hardware has to be chosen.

19

Figure 5. Mounting using bolts on the transversal bars.

Mounting with bolts can be done only through dedicated predrilled holes in the frame

Drilling new holes is forbidden and will void the warranty.

7 Maintenance

In order to ensure optimum module performance, SoliTek recommends the following: If necessary,

the glass front of the module can be cleaned with water and a soft sponge or cloth. A mild, non-

abrasive detergent can be used to remove more stubborn stains. Check the electrical and mechanical

connections periodically and make sure they are clean, safe, complete and secure. In the event of a

problem, consult with a licensed/qualified person.

20

8 Specifications

Table 2. SOLID Bifacial B.60, BLACKSTAR (SOLID Framed) B.60 parameters table.

Parameter \ Model SOLID Bifacial B.60 BLACKSTAR (SOLID Framed)

B.60

Test conditions STC STC

Nominal power 350 W 360 W

Electrical Data @STC

Maximum Power (Pmax) , W 350 360

Voltage at Maximum Power

(Vmpp) , V 33,79 34,44

Current at Maximum Power

(Impp) , A 10,37 10,48

Open Circuit Voltage (Voc) , V 39,66 40,11

Short Circuit Current (Isc) , A 11,01

11,08

Thermal Data

Operating Temperature Range - 40

o

C ÷ 85

o

C - 40

o

C ÷ 85

o

C

Temperature Coefficient of Pmax -0,47%/°C -0,47%/°C

Temperature Coefficient of Voc -0,35%/°C -0,35%/°C

Temperature Coefficient of Isc +0,04% /° C +0,04% /° C

Size & weight data

Length, mm

1778±5

1782

Width, mm

1057±5

1061

Thickness, mm 7,1 35

Weight, kg 30 24

Mounting method

Reference to chapter 6.3 6.4

Other

Maximum reverse current, A 20

Fire class (IEC 61730) A

Maximum system voltage, V 1500

The electrical characteristics are within of the indicated values of ISC (

ϕISC)

±3%, VOC (

ϕVOC)

±3,5%, and

PMPP (

ϕPmax)

±5%, under Standard Test Conditions (STC) (irradiance of 1000 W/m², AM 1.5 spectrum,

and a cell temperature of 25°C / 77°F) and Bifacial Standard Test Conditions (BSTC) (irradiance of

1000 W/m², AM 1.5 spectrum, and a cell temperature of 25°C / 77°F).

All SoliTek SOLID PV panels correspond to electrical safety class II.

Table of contents

Other SoliTek Control Unit manuals

Popular Control Unit manuals by other brands

Parker

Parker D1FV EE Series Brief Operation Manual

Siemens

Siemens SITRANS F M MAGFLO series operating manual

Honeywell

Honeywell SM120 installation instructions

Raytheon Electronics

Raytheon Electronics AUTOHELM Z235 Bidata Round Service manual

CAME

CAME 806XG-0080 manual

resideo

resideo Braukmann D16 installation instructions