D

ISTRIBUTOR

3010

I

NSTALLATION

,

U

SE AND

M

AINTENANCE

ENG

5 / 28

10991838 EN - 0.02 - 04.02.2021

0GENERAL INFORMATIONS

0.1 INTRODU TORY INFORMATION

0.1.1 DEFINITIONS

The definitions are used in this manual as indicated in the following standards and regulations

EN81-20 e EN81-50

Safety regulations for the construction and installation of lifts

UNI EN ISO 14798

Lifts (elevators), escalators and mobile walkways

– Risks assessment and reduction methodology

UNI EN ISO 7010

Graphic symbols: Safety signs and colours

EN12016 e EN12015

Electromagnetic compatibility

CEI EN 61439-1

Low voltage switchgear and control gear assemblies (LV control panels)

0.1.2 MAIN STANDARDS OF REFEREN E

For anything that is not expressly given in this manual, reference should be made to the local standards and

regulations in force, observing in particular:

Directive 2006/42/CE

Machine Directive – in relation to machines, and amending Directive 95/16/CE (recast)

Directive 2014/33/UE

Lifts Directive - on the harmonisation of the laws of the Member States relating to lifts and safety

components for lifts

Directive 2014/35/CE

Low Voltage Directive – on the harmonisation of the laws of the Member States relating to the

making available on the market of electrical equipment designed for use within certain voltage limits

Directive 2004/108/CE

Electromagnetic Compatibility Directive (EMC) – approximation of laws in member States

regarding electromagnetic compatibility, and repealing Directive 89/336/CEE

Rules EN-81 complete series

Safety regulations for the construction and installation of lifts

Refer to the complete series and, in particular to:

EN 81-20

Safety rules for the construction and installation of lifts – Lift for the transport of persons and

goods - Part 20: Passengers and goods passenger lifts

EN 81-50

Safety rules for the construction and installation of lifts – Examinations and tests - Part 50: Design

rules, calculations, examinations and tests of lift components

EN 12015

Electromagnetic compatibility – Product family standard for lifts, escalators and moving walkways

– Emission

EN 12016

Electromagnetic compatibility – Product family standard for lifts, escalators and moving walkways

– Immunity

UNI EN 13015

Maintenance for lifts and escalators: Rules for maintenance instructions

UNI EN ISO 7010

Graphic symbols – Safety signs and colours – Registered safety signs

UNI EN ISO 13857

Machine safety – Safety distance to avoid access to dangerous areas with arms or legs

UNI EN ISO 14121-1

Machine safety – Risks assessment – Part 1: Principles

UNI EN ISO 12100

Safety of machinery - General principles for design - Risk assessment and risk reduction

UNI EN ISO 14798

Lifts (elevators), escalators and mobile walkways

– Risks assessment and reduction methodology

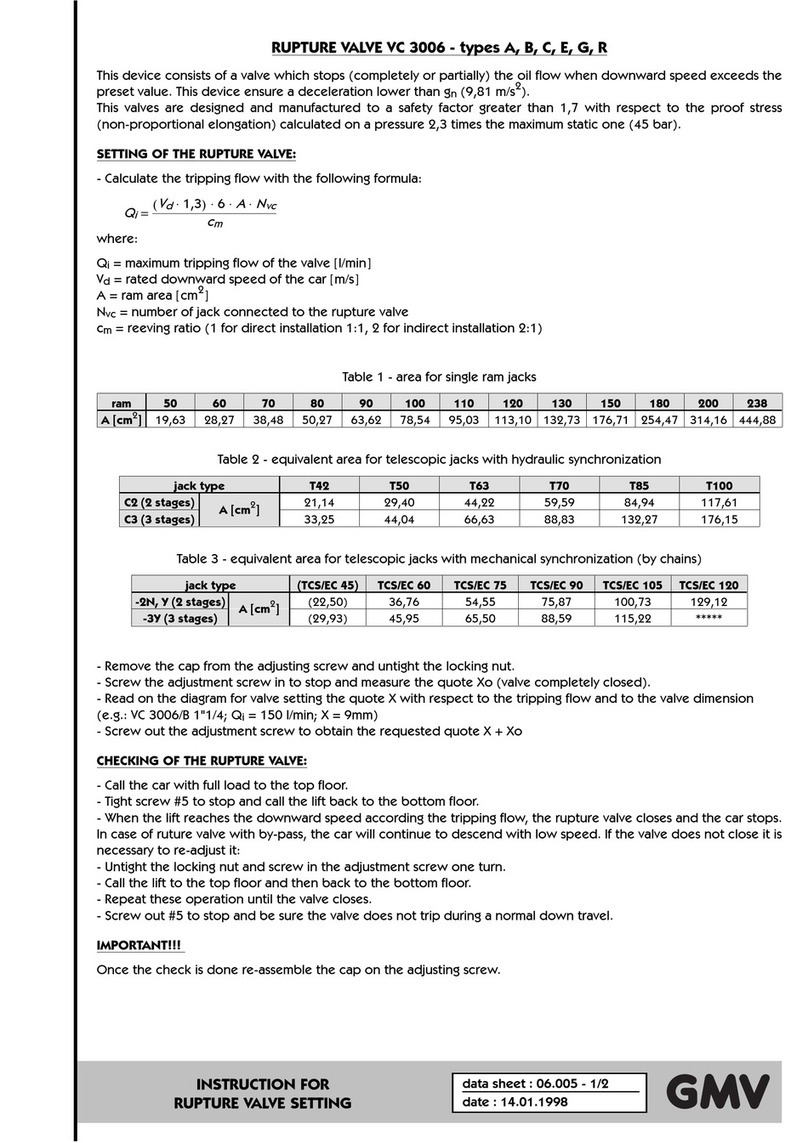

0.1.3 DO UMENTATION FOR INSTALLATION

The documents to use for installation are those required by the applicable standards in force, in particular:

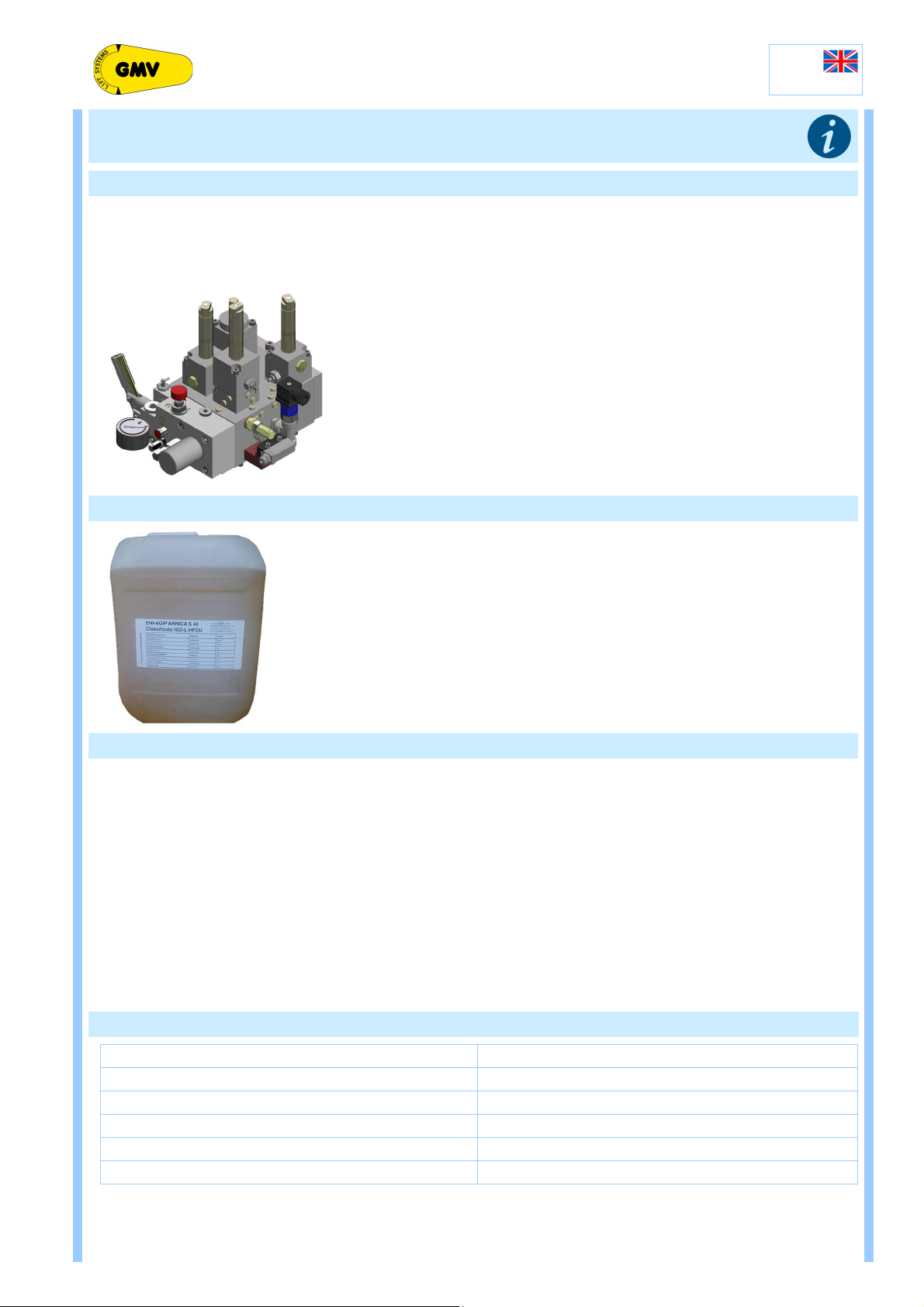

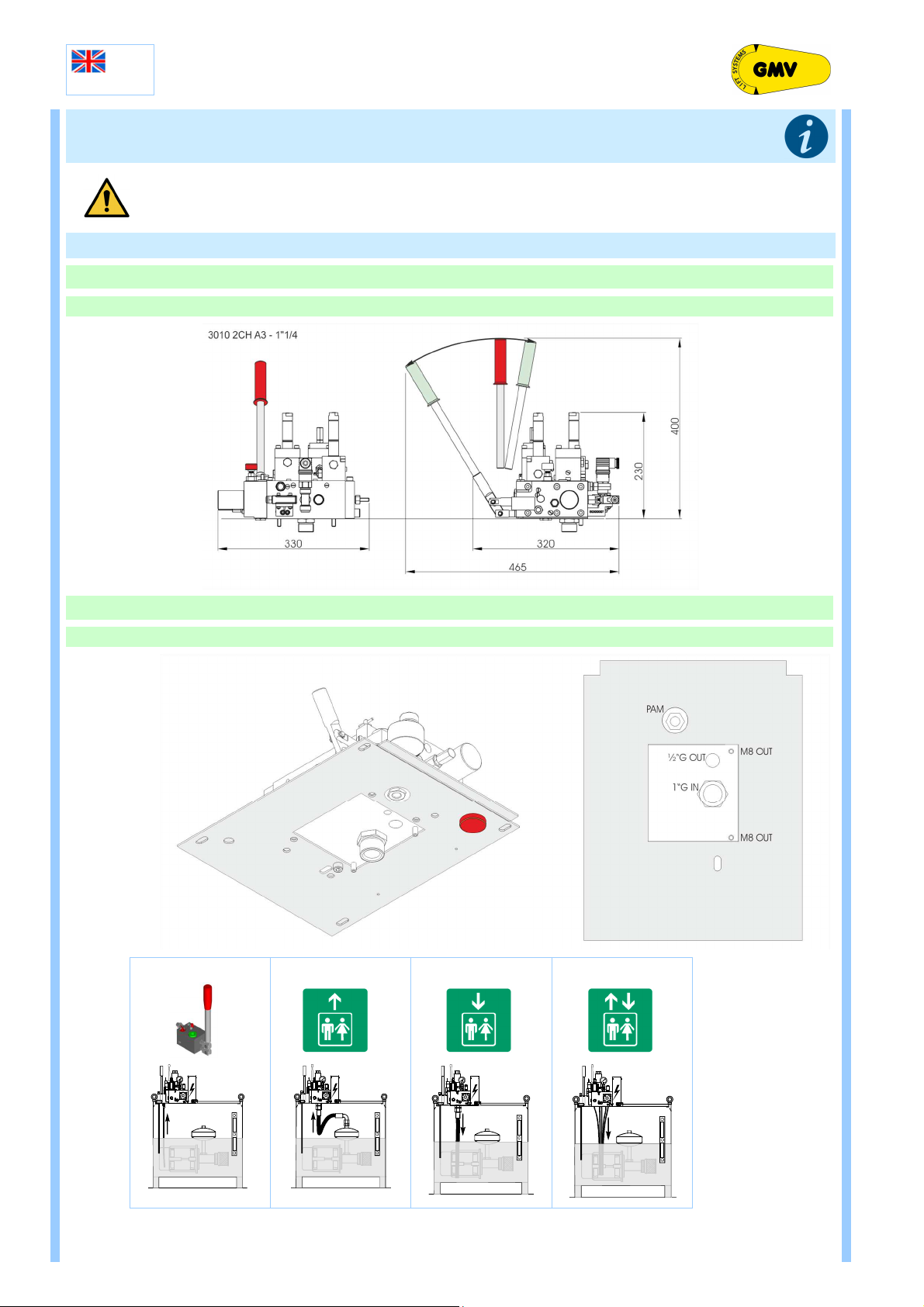

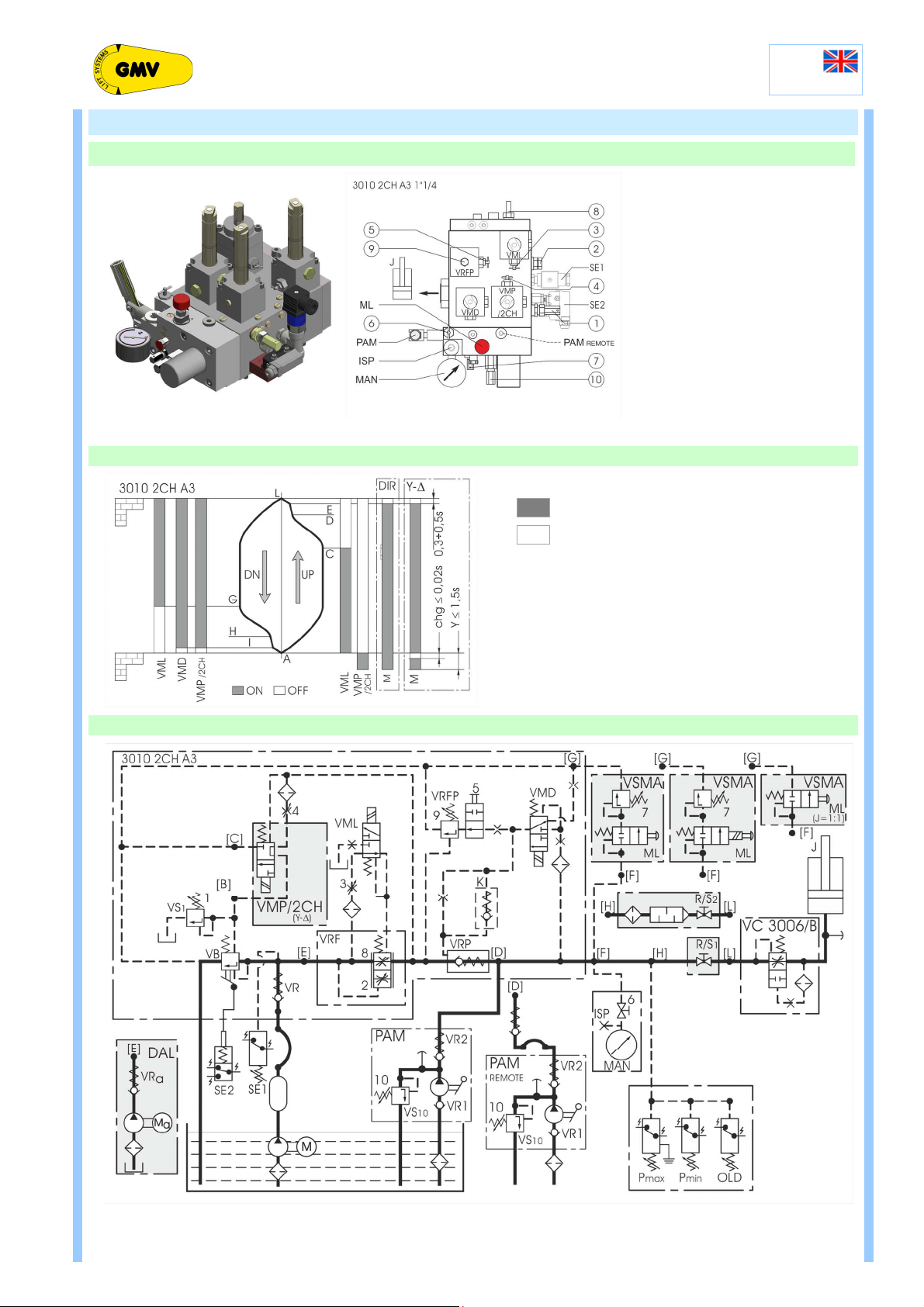

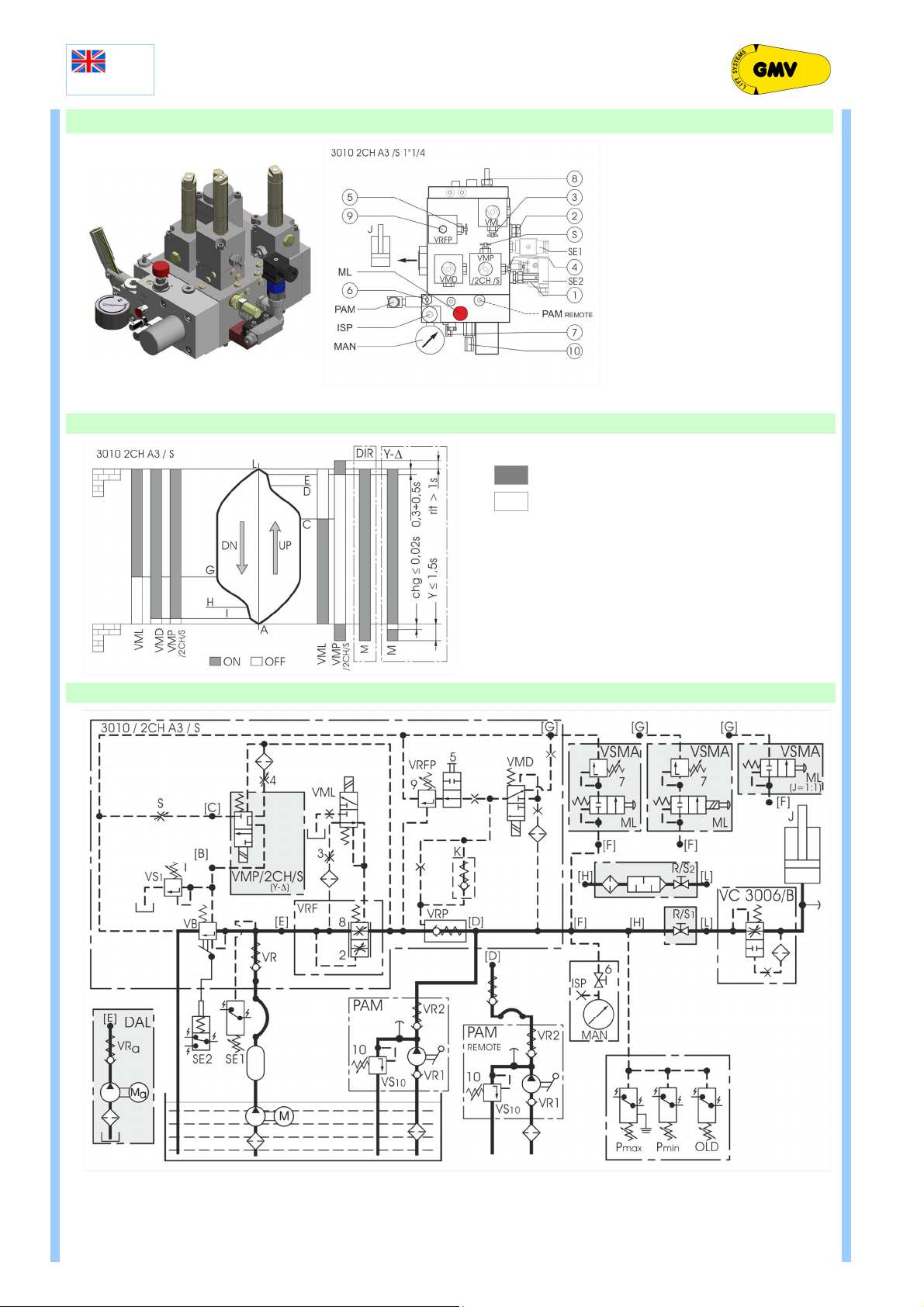

HYDRAULIC DIAGRAMS AND

INSTRUCTIONS OF THE

HYDRAULIC PART AND

RUPTURE VALVE

W

IRING DIAGRAMS AND

I

NSTRUCTIONS OF THE

ELECTRICAL PART AND

CONTROL PANEL

.

T

HIS MANUAL

All the documentation for a correct and safe installation, must be stored by the installation responsible.

Please remember that this documentation is considered part of the plant and must be complete, well stored

and unabridged in every part.

In order to maintain the readability, the documentation shouldn’t be damaged and shouldn’t have missing

parts. Moreover, do not tear or deteriorate sheets during consulting, if printed, the sheets must not be torn

or deteriorated during the consultation.