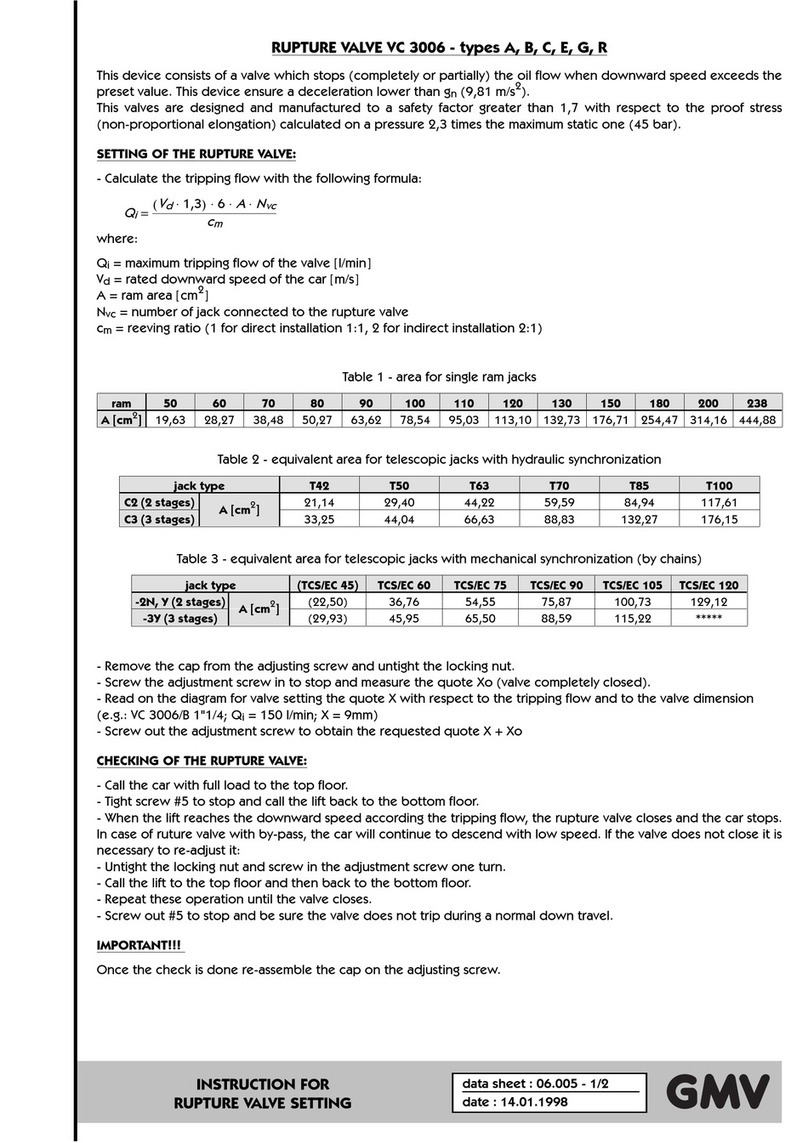

RUPTURE VALVE VC 3006 - types A*,B,R,G,E*

This device consists of a valve which stops (completely or partially) the oil flow when downward speed exceeds the

preset value.Thisdevice ensures a deceleration lower than gn(9,81 m/s2).

These valves are designed and manufactured to a safety factor greater than 1,7 with respect to the proof stress

(non-proportional elongation) calculated on a pressure 2,3 times the maximum static one (45 bar).

SETTING OF THE RUPTURE VALVE :

- Calculate the tripping flow with the following formula:

Qi=

where:

Qi= maximum tripping flow of the valve [l/min]

Vd= rated downward speed of the car [m/s]

A = ram area [cm2]

Nvc = number of jack connected to the rupture valve

cm= reeving ratio (1 for direct installation 1:1,2 for indirect installation 2:1)

- Remove the cap from the adjusting screw and untight the locking nut.

- Screw the adjustment screw in to stop and measure the quote Xo (valve completely closed).

- Read on the diagram for valve setting the quote X with respect to the tripping flow and to the valve dimension

(es: VC 3006/B 1"1/4; Qi = 150 l/min; X = 9mm)

- Screw out the adjustment screw to obtain the requested quote X + Xo.

CHECKING OF THE RUPTURE VALVE:

- Call the car with full load to the top floor.

- Tight screw #5 to stop and call the lift back to the bottom floor.

- When the lift reaches the downward speed according the tripping flow, the rupture valve closes and the car stops

In case of rupture valve with by-pass, the car will continue to descend with low speed. If the valve does not close it is necessary

to re-adjust it:

- Untight the locking nut and screw in the adjustment screw one turn.

- Call the lift to the top floor and then back to the bottom floor.

- Repeat this operation until the valve closes.

- Screw out #5 to stop and be sure the valve does not trip during a normal down travel.

IMPORTANT!!!

Once the check is done re-assemble the cap on the adjusting screw.

(*) not certified

Table 1 - area for single ram jacks

ram HL 55 HL 65HL 75

A [cm2]

28,26 38,46 50,24

ram 50 60 70 80 90 100 110 120 130 140 150 180 200 238

A [cm2]19,63 28,27 38,48 50,27 63,62 78,54 95,03 113,10 132,73 153,94 176,71 254,47 314,16 444,88

Table 2 - equivalent area for telescopic jacks with hydraulic synchronization

jack type T42 T50 T63 T70 T85 T100

C2 (2 stages) A [cm2]21,14 29,40 44,22 59,59 84,94 117,61

C3 (3 stages) 33,25 44,04 66,63 88,83 132,27 176,15

Table 3 - equivalent area for telescopic jacks with mechanical synchronization (by chains)

jack type TCS/EC 60 TCS/EC 75 TCS/EC 90 TCS/EC 105 TCS/EC 120

-2N, Y (2 stages) A [cm2]36,76 54,55 75,87 100,73 129,12

-3Y (3 stages) 45,95 65,50 88,59 115,22 *****

-4Y (4 stages) 56,32 77,64 102,50 ***** *****

V(d13)6AN

vc

⋅⋅⋅,⋅ cm

--------------------------------------------------------

INSTRUCTION FOR

RUPTURE VALVE SETTING

table :

date : 06.005

revision :

page : D19/01/1998

1/3

09/11/2017