EN

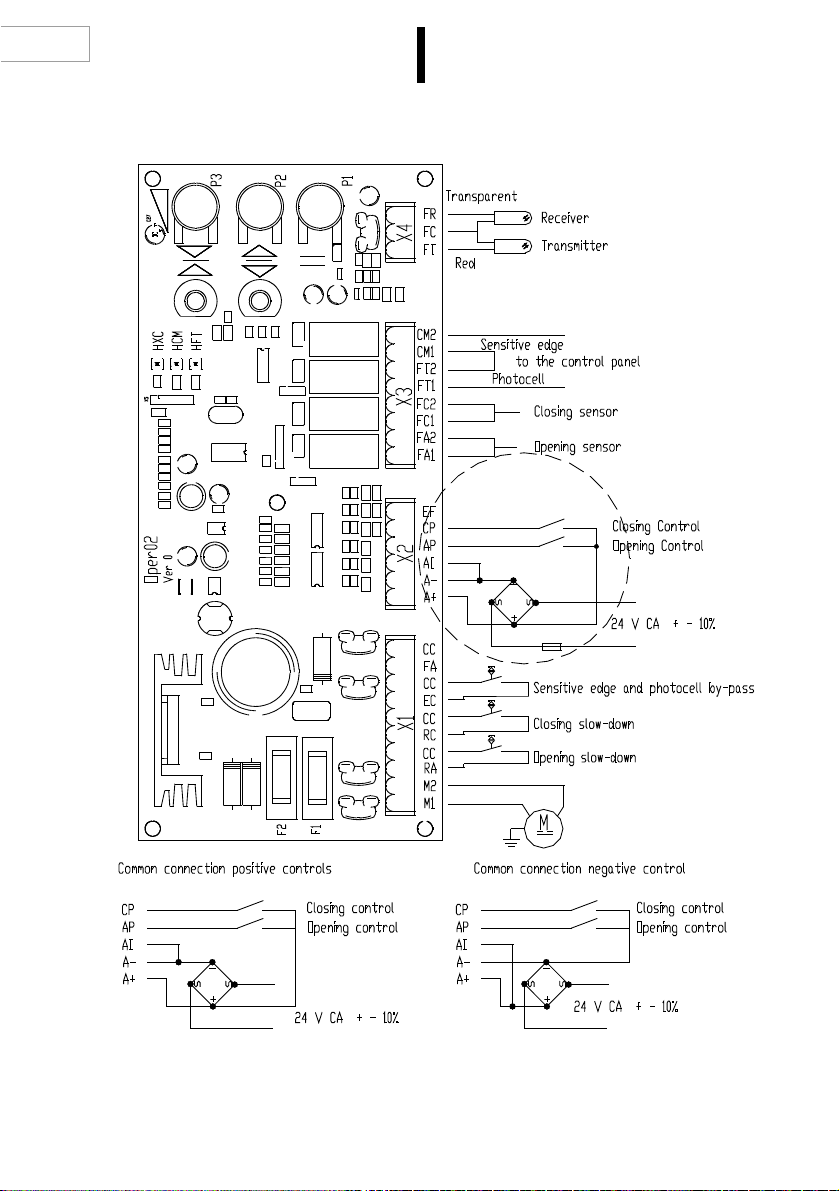

3. 2 CARD CONTROLS

Card OPER02 contains also two push-buttons for the operation in Test mode.

When power supply is connected to the card, if both the push-buttons are kept under pressure

for at least 1 second, the card moves into test mode, thus ignoring the control panel controls.

If the push-buttons are pressed again for 1 second, the card shall resume the standard operating

mode.

Anytime voltage issupplied to the card, itwill set into the standard operation mode, i.e.controlled

from the control panel.

4. OPERATION

The device does not carry out any control autonomously; it will carry out only the controls which

come from the control panel.

The sole exception is the stopping of the doors in case of intervention of either the moving edge

or the photocell.

4.1 DOOR OPENING

Door opening is carried out with the max torque available with no constraint.

The max. speed which can be reached depends upon:

· Trimmer adjustment <I>

· Resisting torque of doors and kinematics

The values ofAcceleration, Deceleration, Opening Slow Speed, Maintaining Current at the End

of Opening are fixed and unchangeable.

The doors open at the established speed until the monostable RAis reached.

Such monostable is to be located in such a way that the slow speed movement is reduced to

the minimum at the end of the deceleration.

If monostable RAis read before the end of the acceleration, as in the case of re-opening of the

doors, the beginning of the deceleration is delayed in compliance with the actual speed of the

doors.

If – in case of door closing - reopening is requested before the RAmonostable is exceeded - la

the reopening shall be carried out at slow speed.

The opening sensor contact (FA1-FA2) opens when the doors are completely open, when the

opening maintaining current is applied.

4.2 DOOR CLOSING

Door closing is carried out with torque control until monostable EC closes.

The doors operate at the established speed until they reach monostable RC. This monostable

is to be adjusted so that – at the end of the deceleration – the movement of the floor doors at

slow speed is reduced to the minimum.

If monostable RC is read before the end of the acceleration, the beginning of the deceleration

is delayed based upon the actual speed of the doors.

16