Henderson Evolve Glass SIM Kit User manual

Evolve –Glass SIM Kit

DOCUMENT TYPE = FITTING INSTRUCTIONS ORIGINAL LANGUAGE = ENGLISH

Maximum door weight = 40kg per leaf –total system 80kg

Maximum door width 2 x 2mtr Track = 760 - 1058mm (Up to 2035 mm clear opening)

About this document

This document addresses qualified personnel only. The mounting must be done by technically educated,

trained and qualified personnel. Electrical wirings have to be completed by suitably qualified specialists.

These instructions describe how to install the track & sliding door gear –for operation of the drive motor & Wiring detail

for the addition of switches & or sensors please refer the Evolve Motor and Wiring Fitting Instructions supplied

The manufacturer’s specifications must be respected, in especially maximum weight restriction of the door leaf. Any

other use of this product is considered inappropriate use.

It is not guaranteed that this product will work in combination with fittings, motors or other electronic devices

supplied by other manufactures.

The appliance is only to be used with the power supply unit provided.

Before you commence work, please read through these instructions. Please store these instructions in a safe place

and pass them on to any future owners. Damage resulting from non –compliance with these instructions and safety

instructions will void the warranty. PC Henderson nor the motor unit manufacturer will assume liability for any

consequential damage.

Fixings required (Not supplied by PCH)

We recommend that suitable wall fixings and screws with a Safe Working Load of at least 80kg are used.

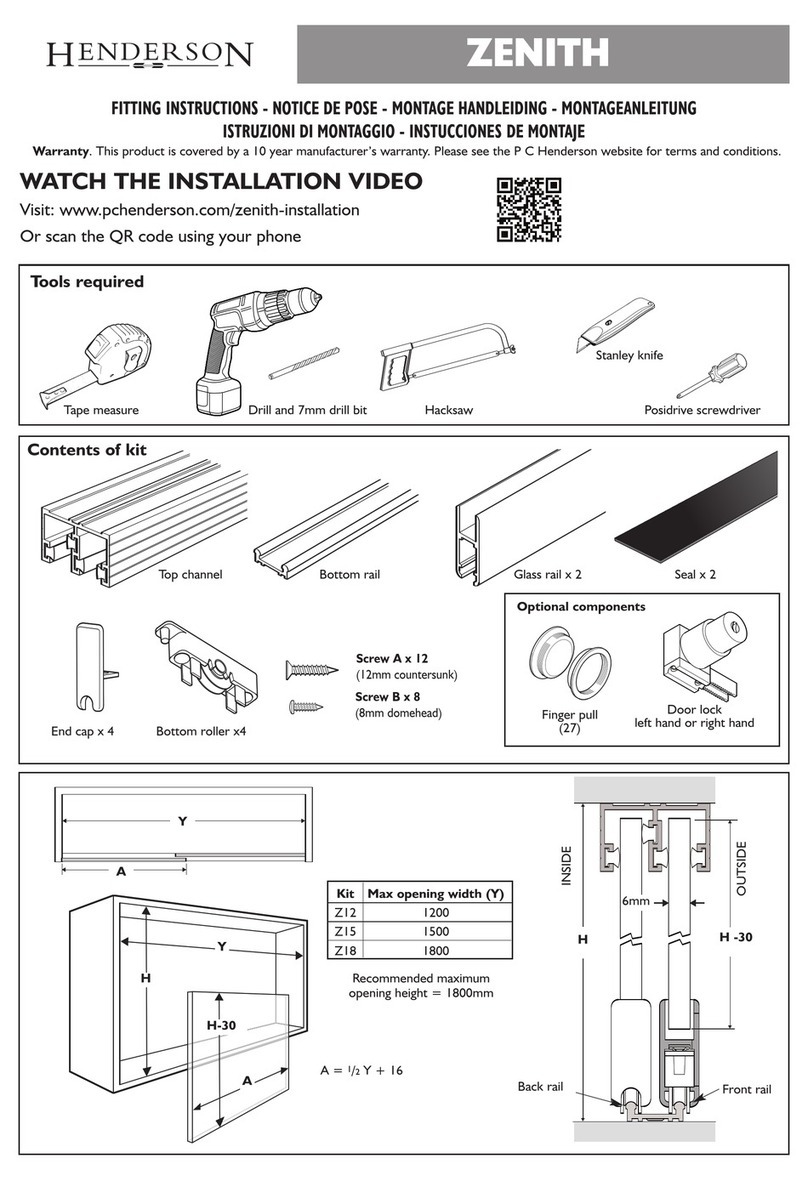

Contents of Kit

80kg

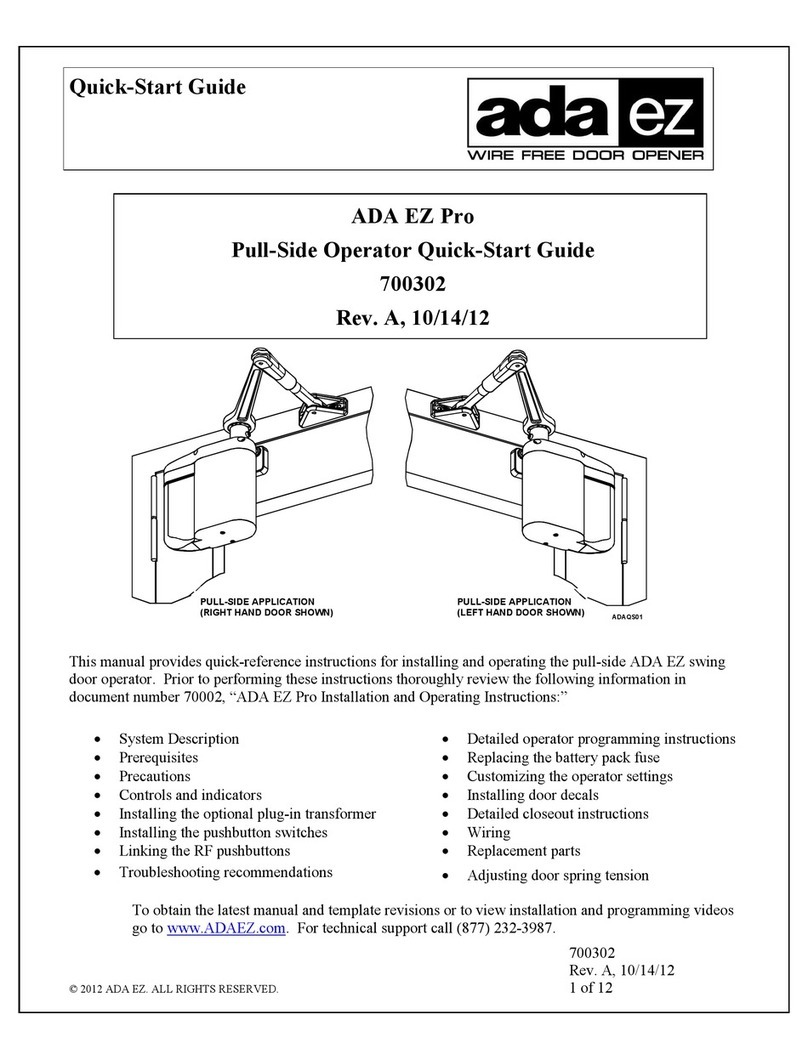

Installations –End elevations

Tools required

Electricians

Screwdriver

Posi Head

Screwdriver

3, 4 & 5mm Allen

keys

Scissors

Torque Wrench

and 6mm bit

Electric Drill &

twist drill

Tape Measure

Spirit Level

3, 10 & 13mm

Spanner

Installation - System layout

CLOSED POSITION

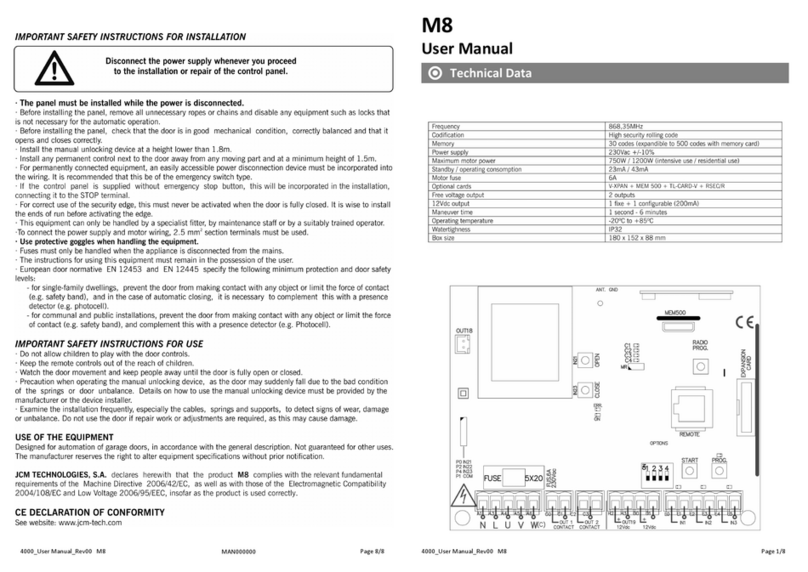

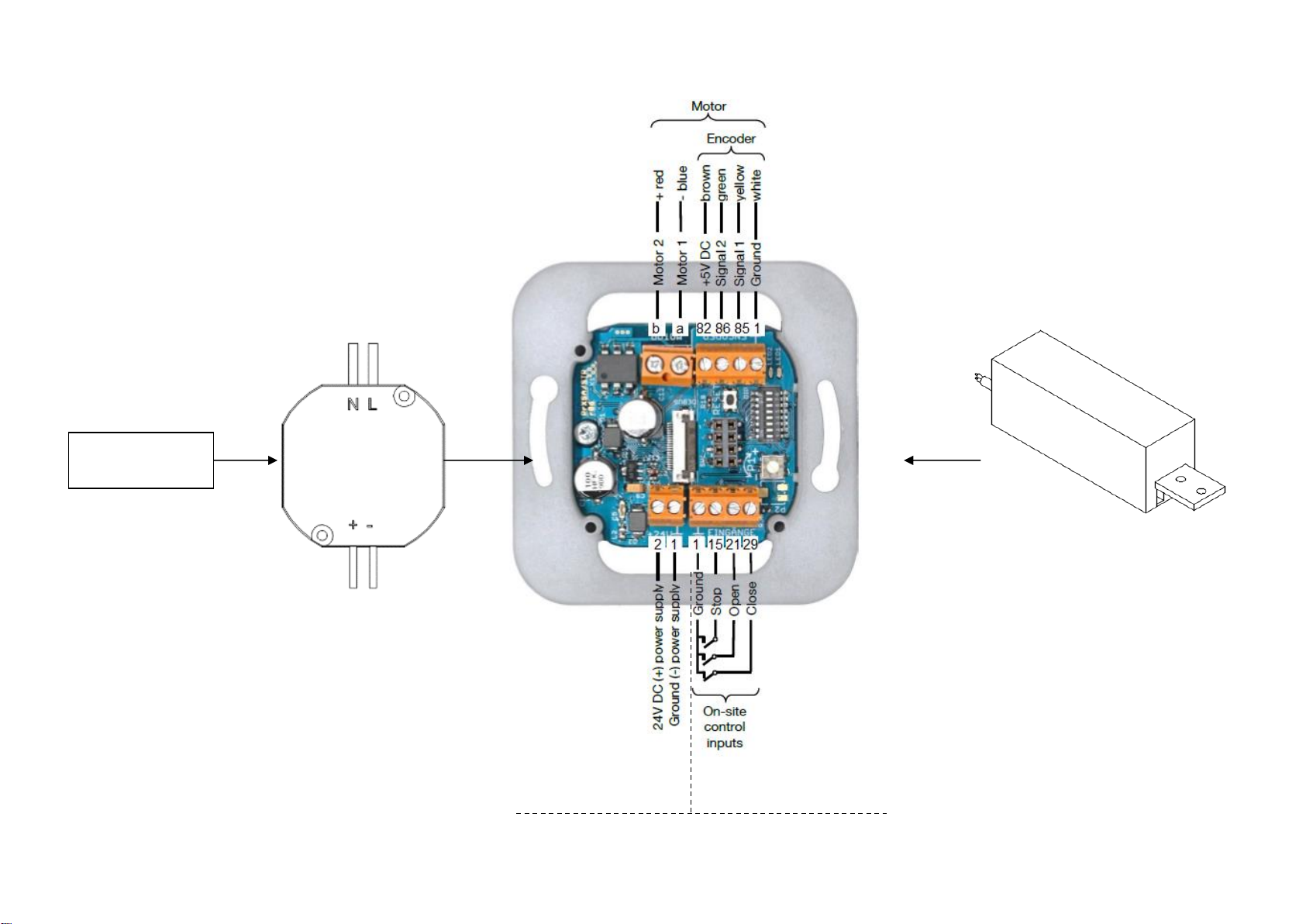

Quick overview –Wiring wall mounted socket

For detailed operation and programming instructions please consult the separate Evolve Motor and Wiring Fitting Instructions supplied

Fused Spur

(Not PCH)

Motor Unit

24V Transformer

Wall mounted control device inputs

Transformer input

Remote sensor or

additional switch input

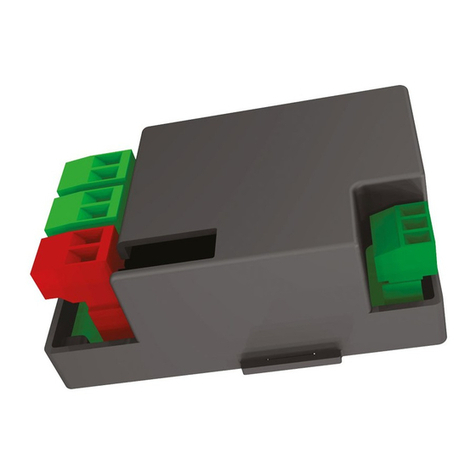

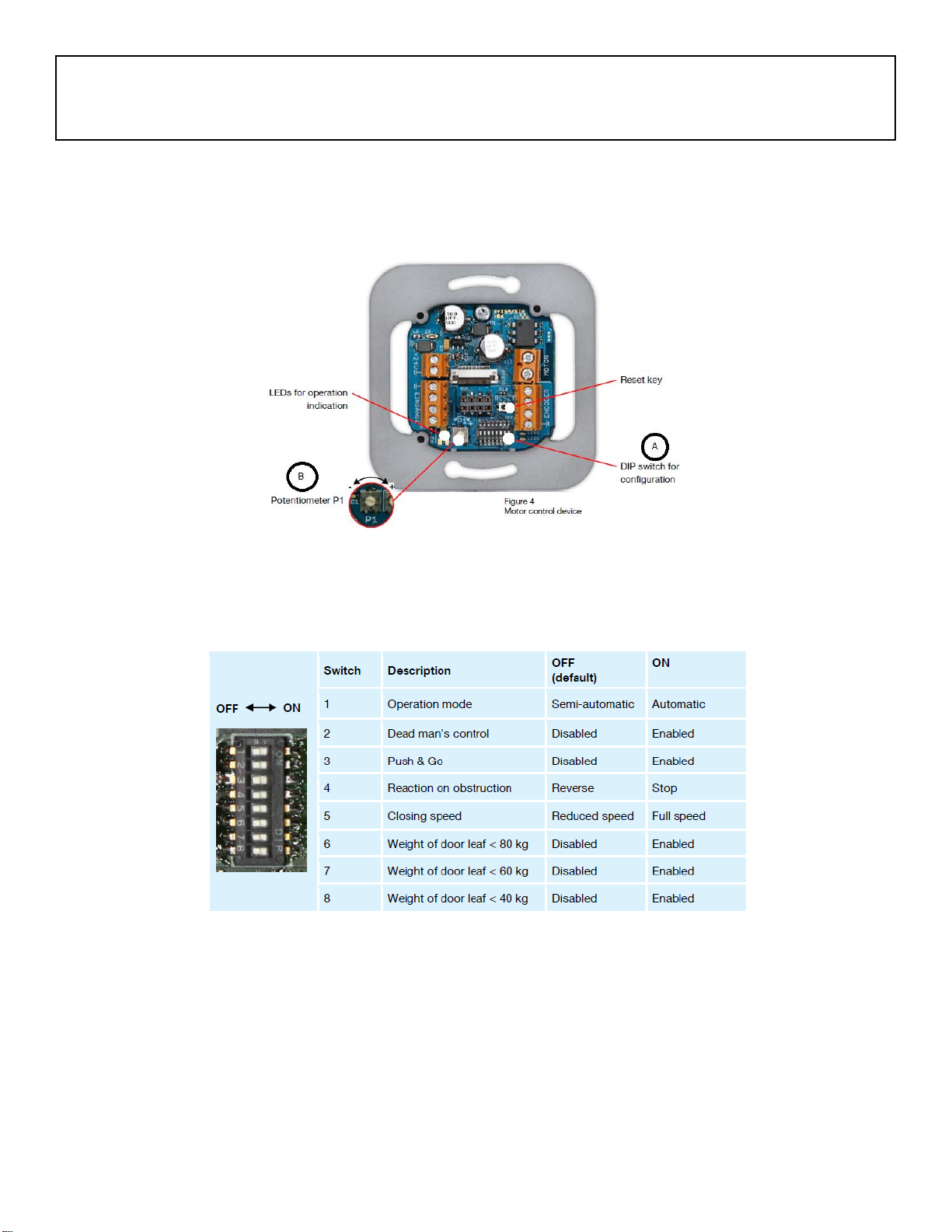

Initial Configuration

The configuration is set via the potentiometer P1, the DIP switch and the reset button. The function of these

elements is described in the following section.

Changes to configuration will only take effect once the configuration mode has been selected, modified and

then exited.

A –Configuration of DIP switches - Set desired parameters, while power is off.

B –Potentiometer Detail –Automatic closing delay time

To prolong automatic closing delay time –Turn potentiometer Clockwise

To reduce the automatic closing delay time –Turn potentiometer Anti clockwise

NOTICE: Potentiometer have a right and left stop point –which must not be overtightened. Adjust

potentiometer slightly with an appropriate tool. Damage to control device may result in malfunction.

Quick overview –Wiring wall mounted socket

For detailed operation and programming instructions please consult the Evolve Motor and Wiring Fitting Instructions

supplied

1. Operation mode semi- automatic / automatic

When semi-automatic mode is set the drive will not close automatically. The potentiometer is without function.

When the automatic mode is set the drive closes automatically.

2. Dead man’s control:

When dead man’s control is activated the drive will only operate, as long as an input is applied.

Switch 1 is inactive, when dead man’s control is selected.

3. Push & go:

With push & go enabled the drive starts to move, as soon as the door leaf is pushed manually.

4. Reaction on obstruction:

When reverse is set the drive stops and starts to move in the opposite direction, as soon as an obstruction is detected.

Otherwise it will stop until a new command is given. This is only possible in semi-automatic mode).

5. Closing speed:

By default the closing speed is slower than the opening speed. The closing speed can be set as fast as the opening speed, by

setting this switch to ON>

6. To 8. Maximum door speed

The maximum speed has to be set via these switches.

Maximum speed is dependent on the door leaf weight according to DIN EN 18650.

6: Weight of door leaf up to 80 kg > Maximum speed is 20cm/s

7: Weight of door leaf up to 80 kg > Maximum speed is 23cm/s

8: Weight of door leaf up to 80 kg > Maximum speed is 26cm/s

When no switch is activated, the lowest speed is set (20 cm/s).

When more than one switches are activated, a reduced speed is set (12 cm/s).

Perform Reset

Switch power supply on.

Control device in delivery status or after power cut:

Red LED blinks continuously twice with a short break of 1.5sec.

Press RESET for about 2 seconds.

Red LED blinks continuously.

Check driving direction of motor with control keys:

When pressing OPEN, door has to open and when pressing CLOSE, door has to close.

→ when driving direction is wrong:

Swap motor cables (terminals MA and MB), check driving direction again.

Move door in middle position by pressing and holding the control keys.

Press RESET for about 2 seconds.

Red LED lights up permanently,

green LED lights up during motor activity.

Door moves in the open position,

Door moves in the closed position,

Door moves in the open position.

LED’s go out.

Check functionality

Test, if the door shows desired behavior.

In case of malfunction check electrical connections and configurations.

→for electrical connections refer to chapter 5.3 of the Evolve Motor and Wiring Fitting Instructions supplied

→for configuration refer to chapter 6.1 of the Evolve Motor and Wiring Fitting Instructions supplied

→Repeat initial operation, if necessary.

Initial operation is completed, when function is correct.

Quick overview –Wiring wall mounted socket

For detailed operation and programming instructions please consult the separate Evolve Motor and Wiring Fitting Instructions

supplied

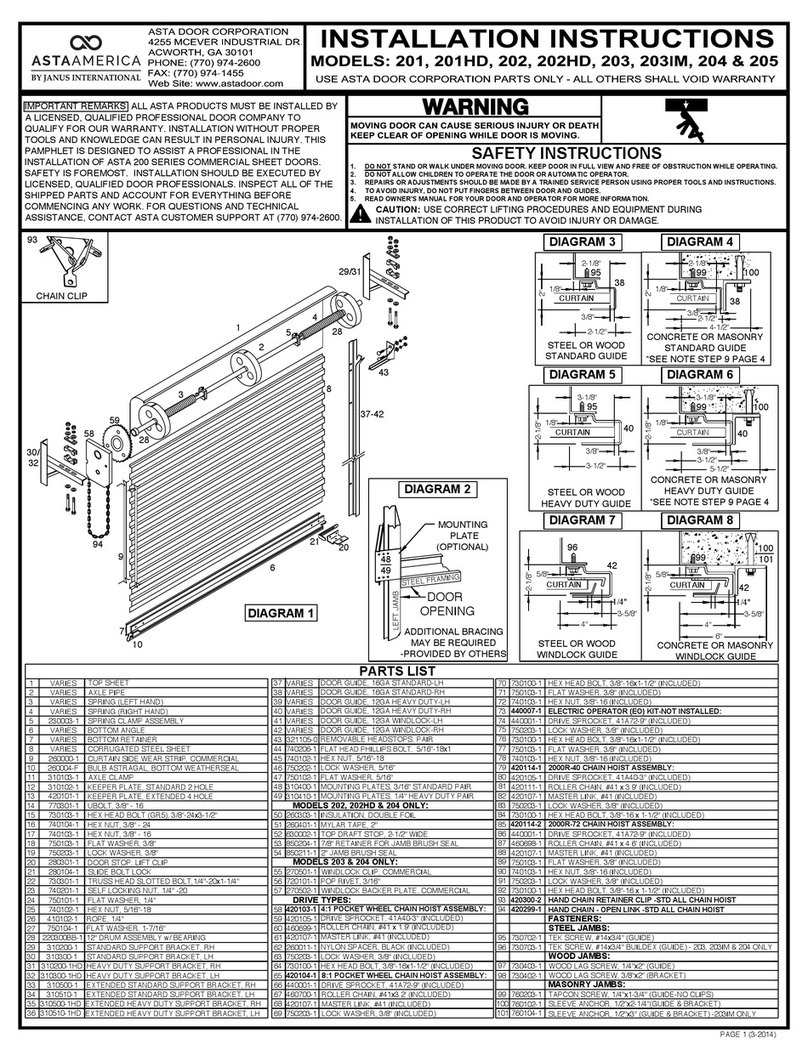

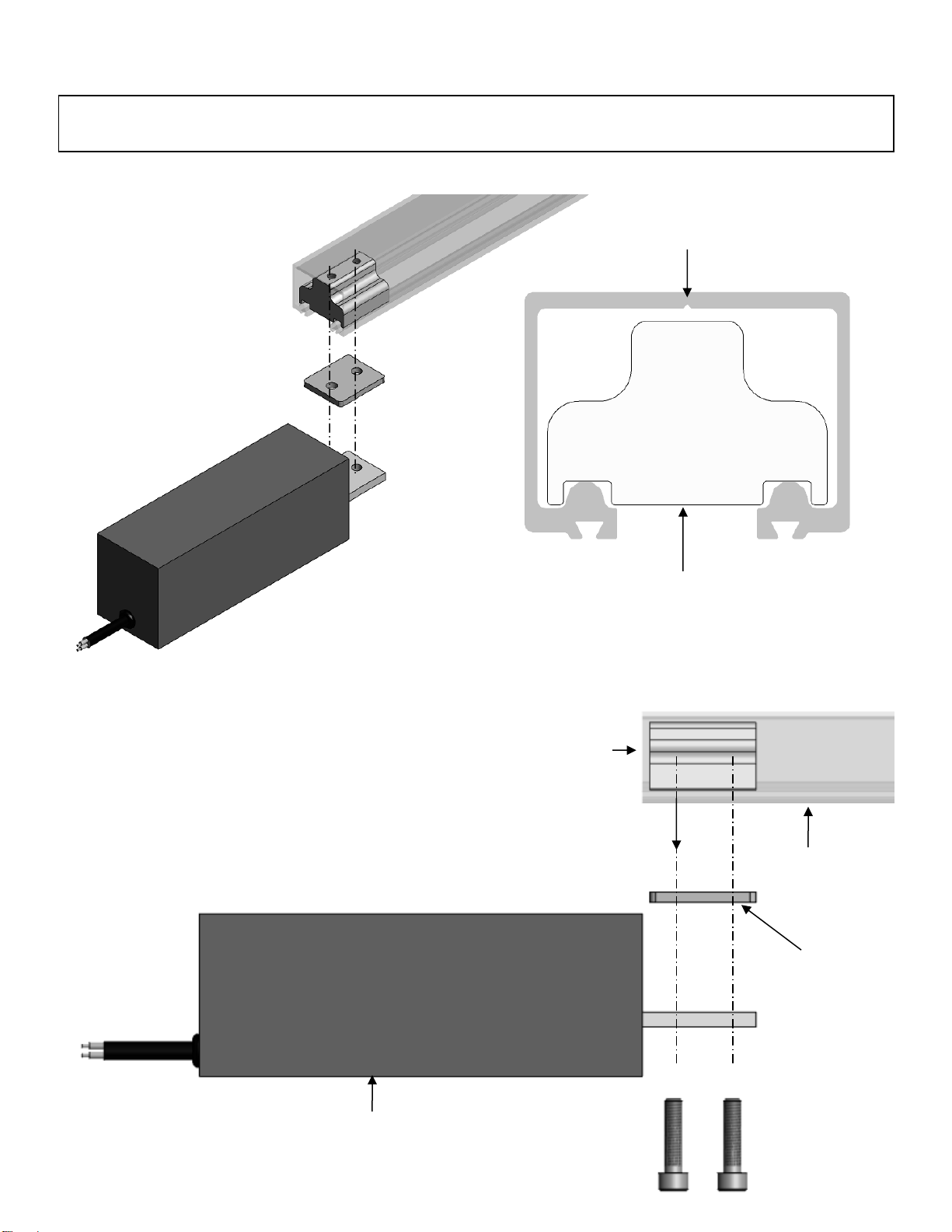

1. Secure motor unit to track by inserting block into track and tightening bolts to clamp over

bottom of track

Track

Connector block

Connector Block

Spacer

Track

Motor

M6x25 Bolts

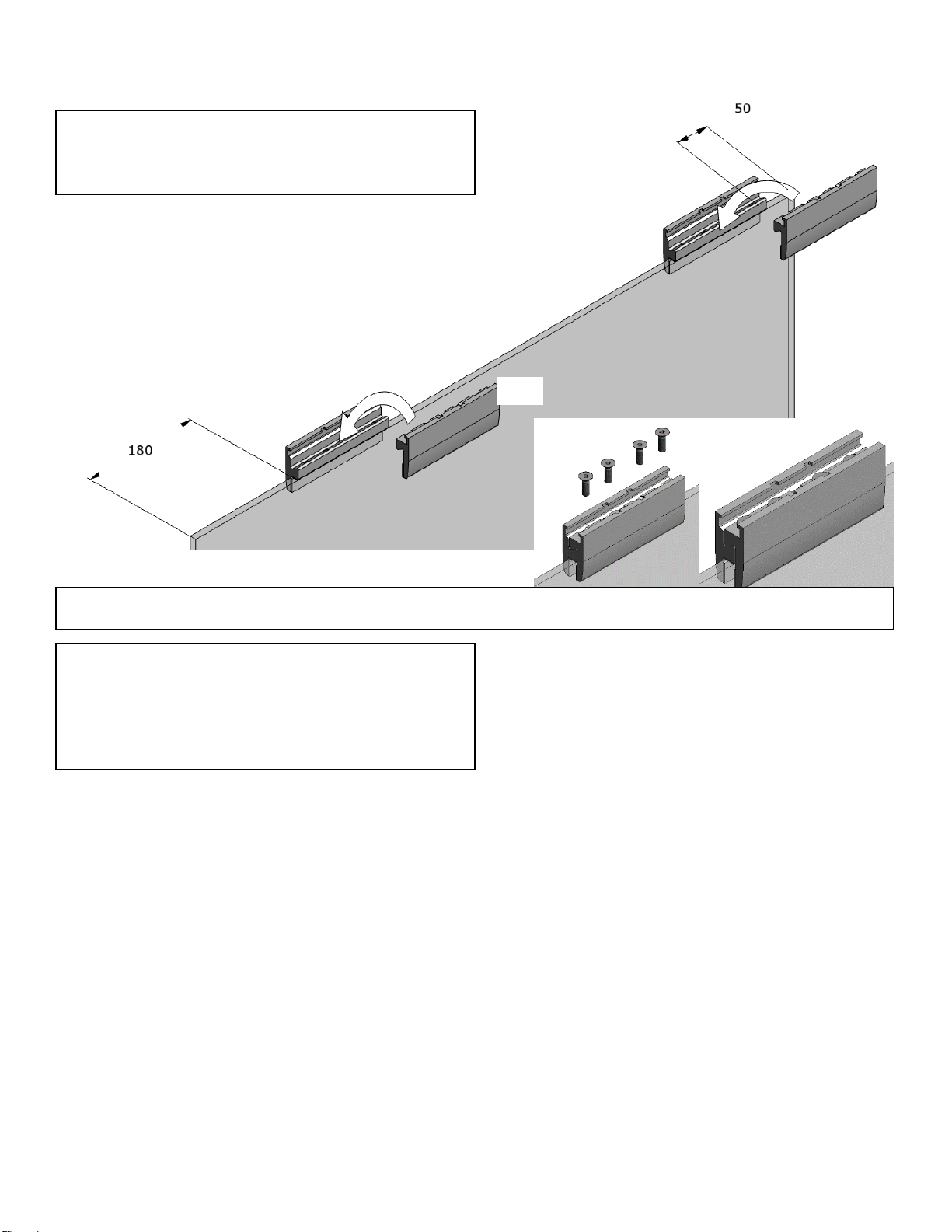

180mm Offset to

accommodate door under

motor unit

2. Door and hardware preparation (overview)

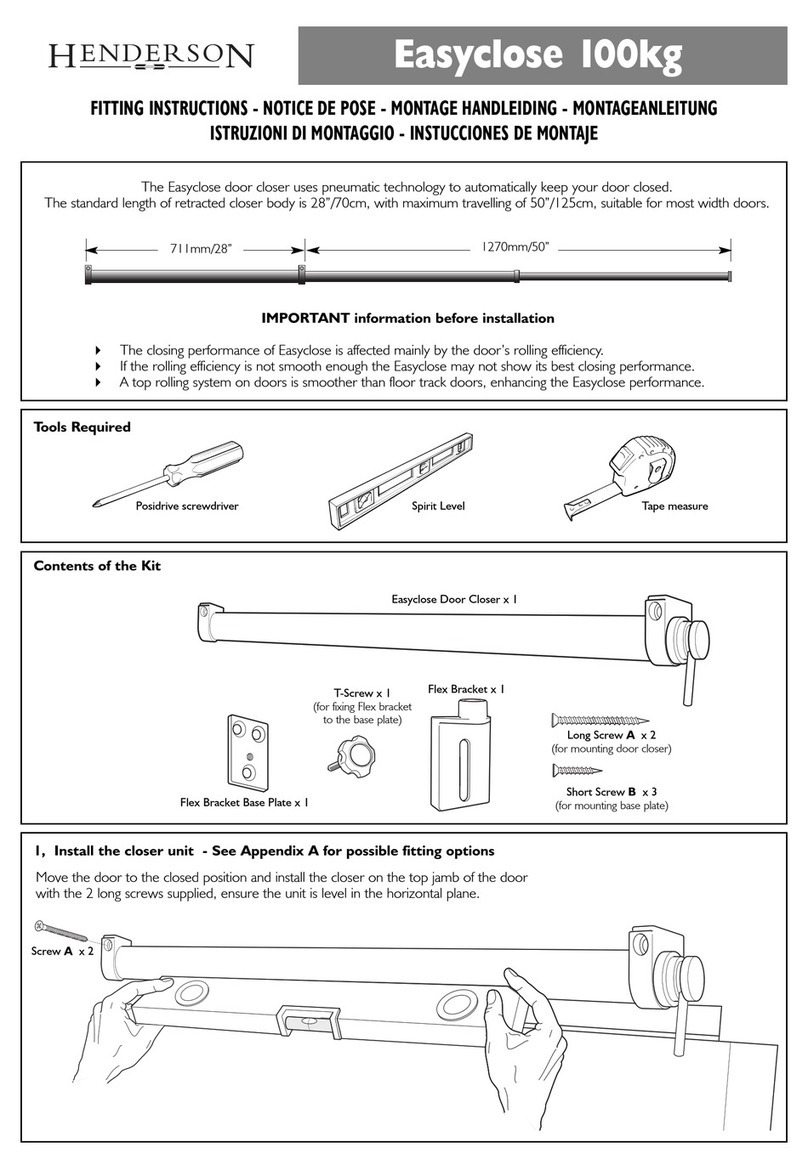

3. Attach glass clamps (Panel positioned under motor highlighted)

4. Attach belt clamp location clamp centrally (ensure correct belt clamp orientation see panel 2)

a. Position first half of glass clamp

b. Locate second half of glass clamp over knee of first

c. Secure glass clamp with screws

d. Attach spacer block with screws to top of clamp

e. Attach belt clamp with screws on to top of spacer

a. Position first half of glass clamp

b. Locate second half of glass clamp over knee of first

c. Secure glass clamp with screws

a.

b.

c.

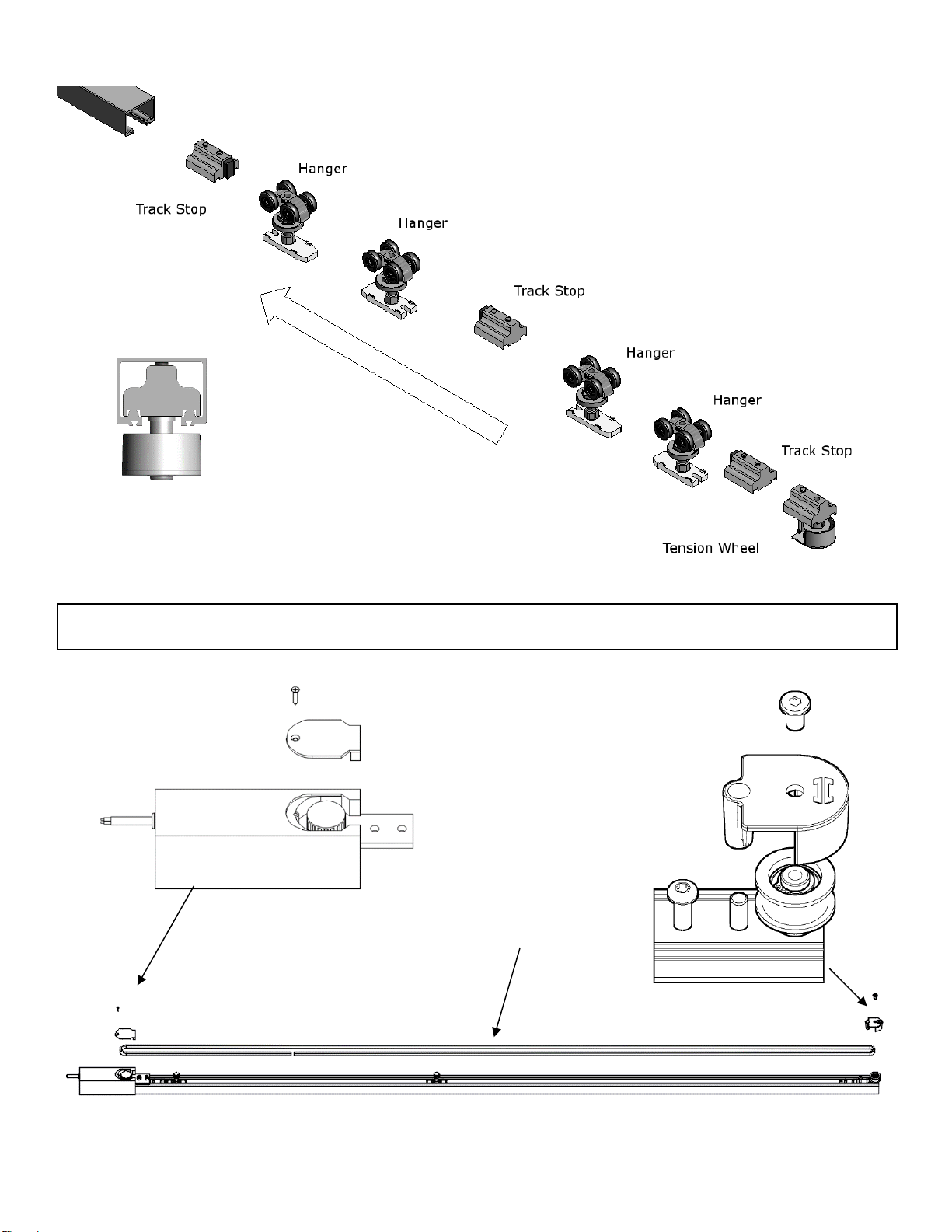

7. Insert track components

5. Secure track in face fixing installation –

spacing between brackets is 600mm MAX

(Use suitable wall anchors –NOT PCH)

6. Secure track soffit fix installation –spacing

between brackets is 600mm MAX

(Use suitable wall anchors –NOT PCH)

1/SS bracket

Fit suitable wall anchors

a.

d.

c.

b.

e.

Toothed belt

Tension wheel

arrangement in track

8. Remove covers to allow toothed belt to be attached

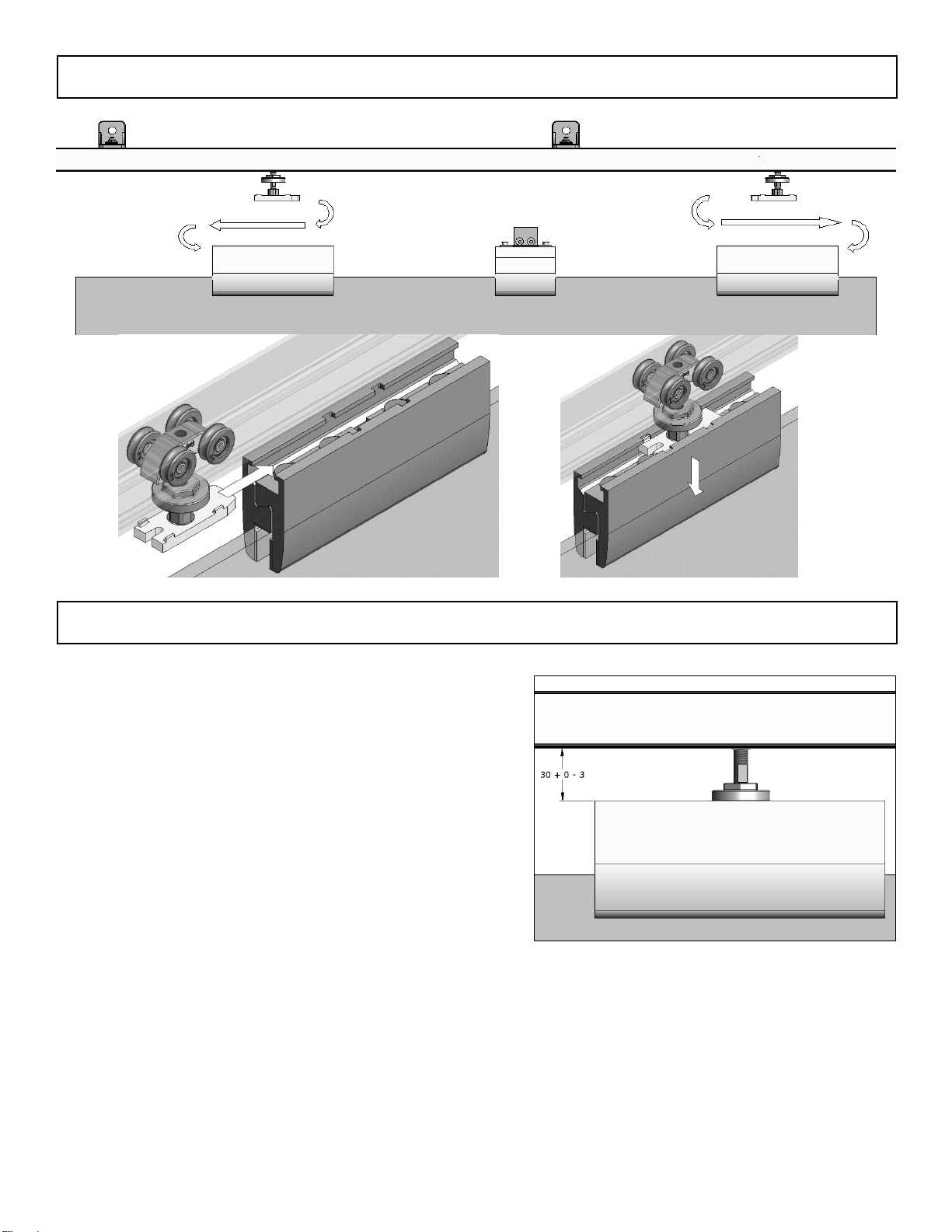

9. Hang glass door

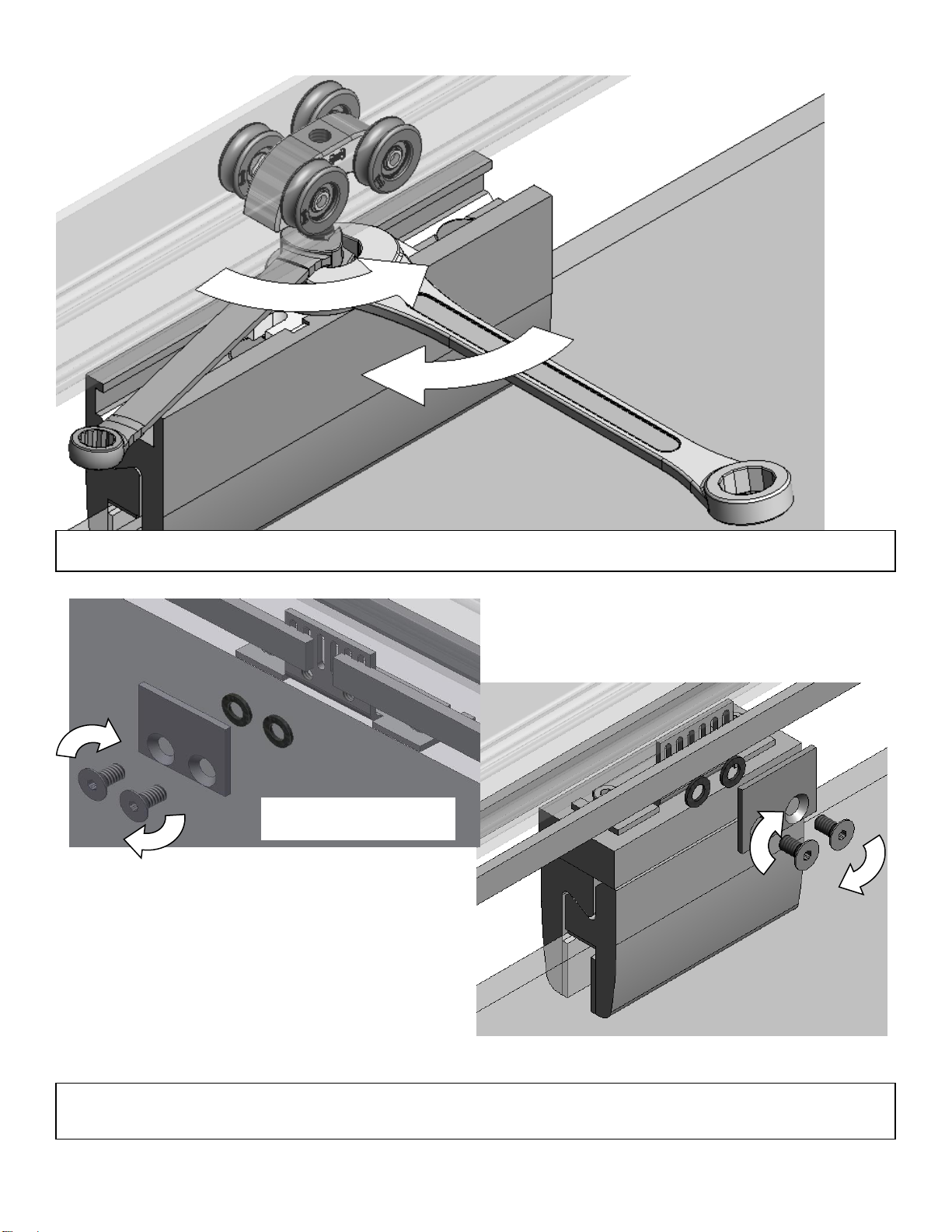

10. Set door height

12. Tension toothed belt –Push tension wheel assembly so that the belt is torte and secure

assembly in position by tightening the M6 grub screw

11. Loosen belt clamp –Cut belt to length –Tighten to secure belt

Tighten to clamp belt

14. Set track stops to limit travel

Tighten

once

position

set

13. Fit Door Guide using spirit level

Adjust door stop if required before

fixing to ensure door is vertical

Please Note

The original language of these instructions are English.

The airborne noise of the system under normal operating conditions

does not exceed 70dB (A).

General Safety Precautions

This installation is intended for professionally competent personnel

only.

Installation, Electrical connections and adjustments must be performed

in accordance with Good Working Methods and in compliance with

applicable regulations. Before installing the product, carefully read the

instructions. Bad Installation could be hazardous.

The packaging material (plastic, polystyrene, etc.) should not be

discarded in the environment or left within the reach of children, as

these are a potential source of hazard.

Before installing the product, make sure it is in perfect condition.

Do not install the product, make sure it is in perfect condition. Do not

install the product in an explosive environment and atmosphere; gas or

inflammable fumes are a serious risk hazard. Before installing the

system, ensure all structural changes relating to safety clearances and

protection or segregation of all areas where there is a risk of being

crushed, cut or dragged, and danger areas in general.

Make sure the existing structure is up to standard in terms of strength

and stability.

Each installation must clearly show the identification details of the

motorized door or gate.

Apply hazard area notices required by applicable regulations.

The electricity supply must be isolated at tis source before attempting

installation or maintenance.

Disclaimer

PC Henderson nor the motor unit manufacturer take responsibility for

failure to use Good Working Methods in building the frames to be

motorized or for any deformation occurring during use. PC Henderson

and the motor declines all responsibility in the event of component

parts being fitted that are not compatible with the safe and correct

operation.

For repairs or replacements of products only original spare parts must

be used.

Installer responsibility

The installer should provide technical documentation once the

installation is complete, this should include.

- EC declaration of conformity with machinery directive

- Installation manual

- Maintenance / Trouble shooting guide (supplied in the drive

unit manufacturer operation manual)

- The installer is responsible for affixing final CE mark upon

the installation.

668775 –LVL02 –JUNE 2019

Tighten to position stops

Manufacturers Declaration of Incorporation

Manufacturer: PC Henderson Ltd

Durham road

Bowburn

Durham

DH6 5EN

Telephone: 0191 3777345

Fax: 0191 3773166

Hereby declares that the electromechanical automatic door operating

system. Evolve

Evolve Glass

Evolve SIM

Are intended to be incorporated into machinery or to be assembled

with other machinery to constitute machinery covered by directive

2006/42/EC

It is in conformity with the provisions of the following directives.

Electromagnetic Directive 2004/108/EC

Low Voltage Directive 2006/95/EC

The technical file is maintained at:

PC Henderson Ltd

Durham road

Bowburn

Durham

DH6 5EN

The authorized representative located within the community is

Fergus Pickard

Product Development Director

PC Henderson Ltd

Durham Road

Bowburn

Durham

DH6 5EN

The above named undertakes to transmit in response to a reasoned

request by national authorities, relevant information on the partly

completed machinery.

Fergus Pickard, Product Development Director

Bowburn, Durham

19/10/17

Avoid operating in the proximity of moving mechanical parts

Do not entre the field of danger of the motorised door while in

motion.

Do not obstruct the motion of the motorised door as this may

cause a situation of danger.

Do not lean against of hang on the barrier when it is moving.

Do not allow children to play or stay within the field of action of

the motorised door.

Keep remote control or any other control devices out of reach

of children, In order to avoid possible involuntary activation of

the motorised door.

In the case of breakdown or malfunction of the product,

disconnect form the mains, do not attempt to repair or

intervene directly & contact only qualified personnel.

Failure to comply with the above may create a situation of

danger.

All cleaning maintenance or repair work must be carried out by

qualified personnel.

In order to guarantee that the system works efficiently and

correctly it is indispensable to comply with the manufacturers

indications thus having a periodic maintenance of motorised

door carrier out by qualified personnel. In particular regular

checks are recommended on order to verify that the safety

devices are operating correctly.

All installation, maintained and repair work must be

documented and made available to the end user

Operating Instructions for Evolve Automation Sliding Door System

Release Operation

In the event of malfunction or these is no mains power, move the door manually.

General Safety Precautions

The following precautions are an integral & essential part of the product and must be supplied to the end user. Read them carefully

as they contain important indications for the safe installation, use and maintenance. These instructions must be kept and forwarded

to all possible future users of the system. This product must be used only for that which it has been expressly designed; any other

use is to be considered improper and therefore dangerous.

The manufacturer cannot be held responsible for possible damage caused by improper erroneous or unreasonable use.

Installer

Installer training available upon request, please note this attracts a fee.

EC Declaration of Conformity –Machinery Directive 200642/CE Schedule II Part 2

Manufacturer:

PC Henderson Ltd

Address:

Durham Road, Bowburn, Durham, DH6 5EN

Name and address of authorized Installer:

Hereby Declare:

Installation at: (Installation address)

Conforms to Directive:

States that it fulfils the application portion of the following standard

Date & Location of signature:

Signature of the person legally responsibility:

This completed document forms part of the European conformity (CE marking) - to be completed by installer and

forwarded to end user.

Evolve –80kg

Evolve –SIM Kit

Evolve - Glass

2006/42/CE –Machinery directive

Must be kept for ten years from installation date.

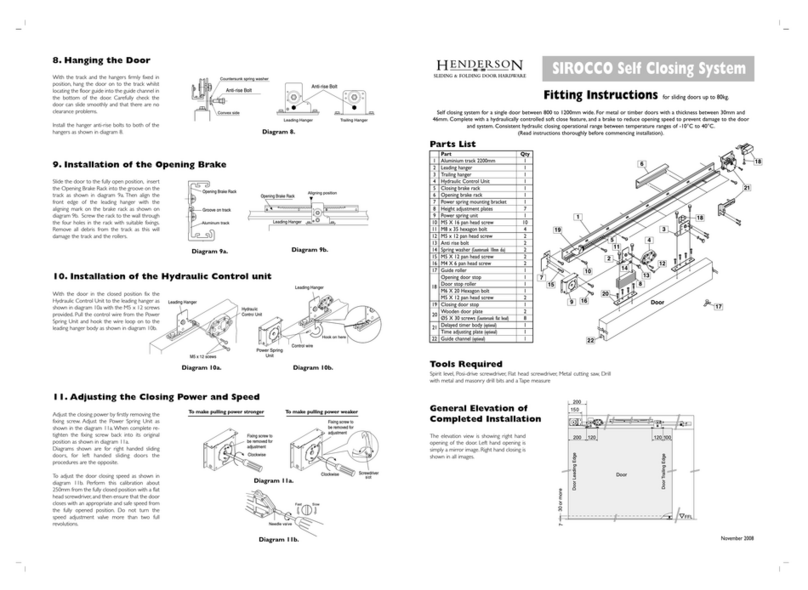

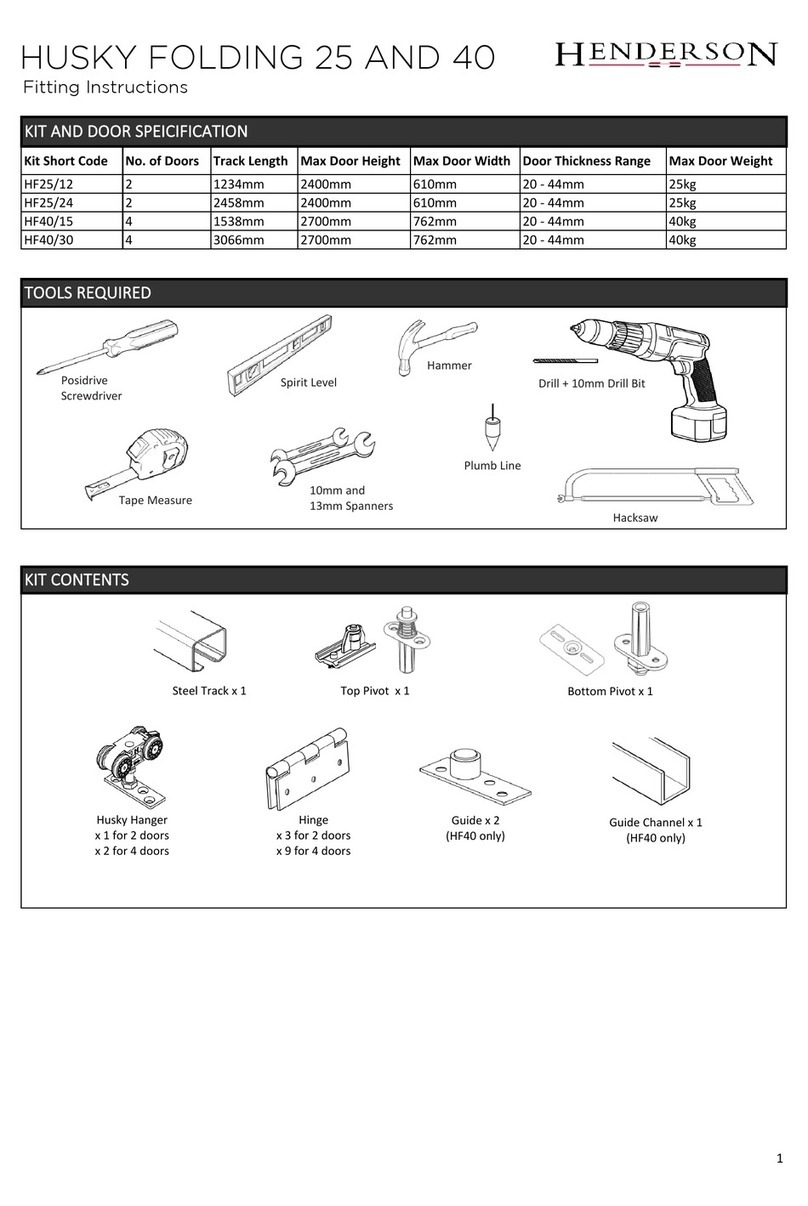

This manual suits for next models

1

Table of contents

Other Henderson Door Opening System manuals

Henderson

Henderson HUSKY 100 User manual

Henderson

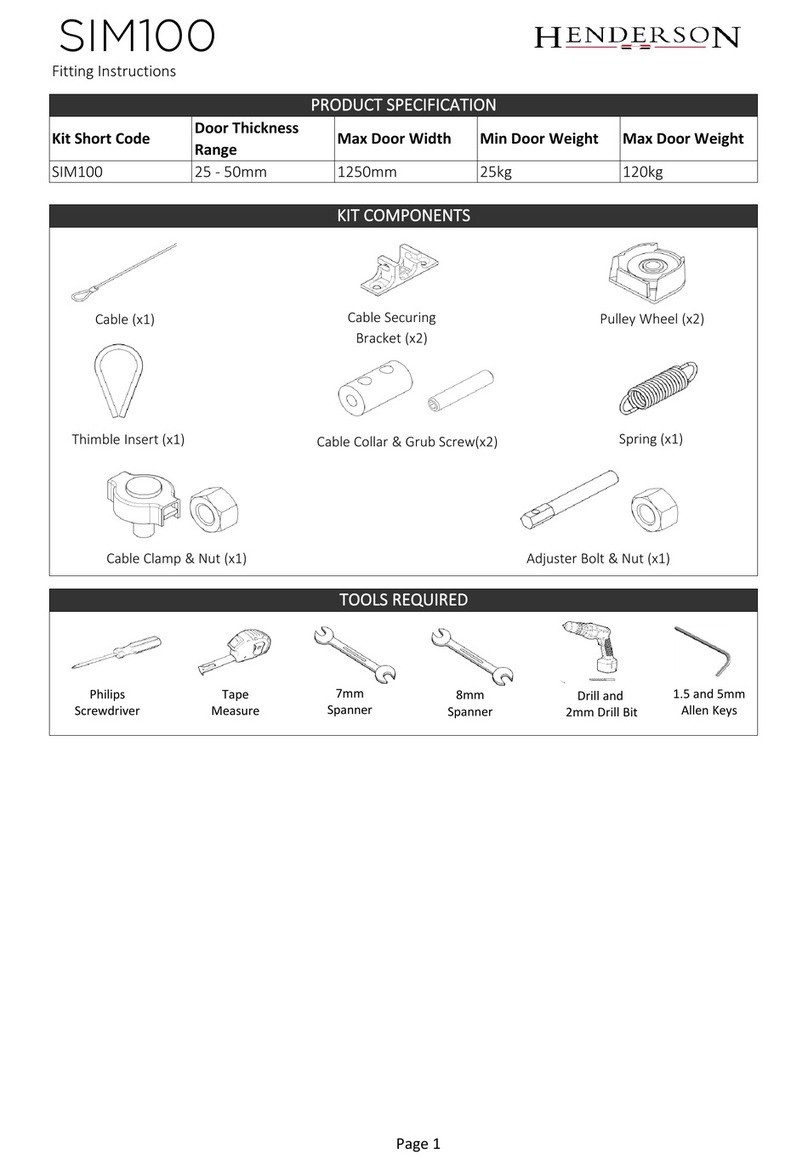

Henderson SIM100 User manual

Henderson

Henderson Easyclose User manual

Henderson

Henderson SIROCCO User manual

Henderson

Henderson EVOLVE POCKET DOOR PRO Series User manual

Henderson

Henderson HUSKY Folding 25 Series User manual

Henderson

Henderson HUSKY 50 User manual

Henderson

Henderson Bifold User manual

Henderson

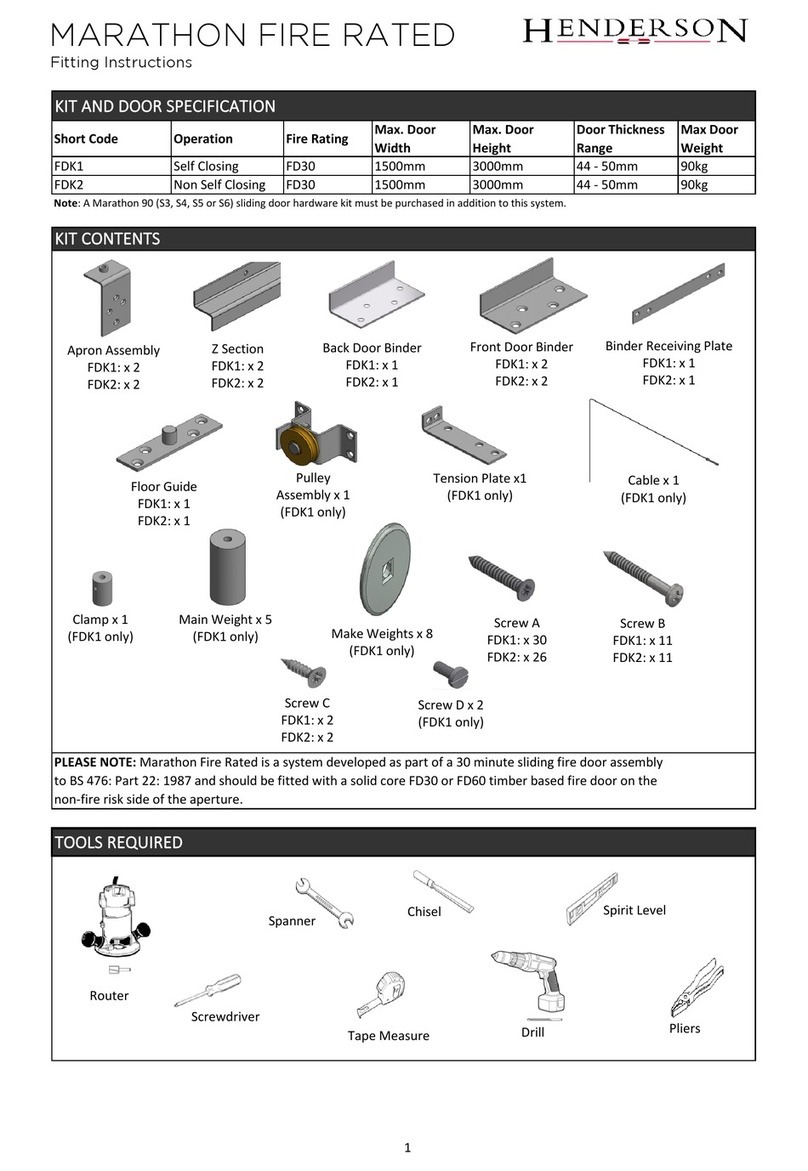

Henderson MARATHON FDK1 User manual

Henderson

Henderson SIM100 User manual