gpelectric.com | [page 7]

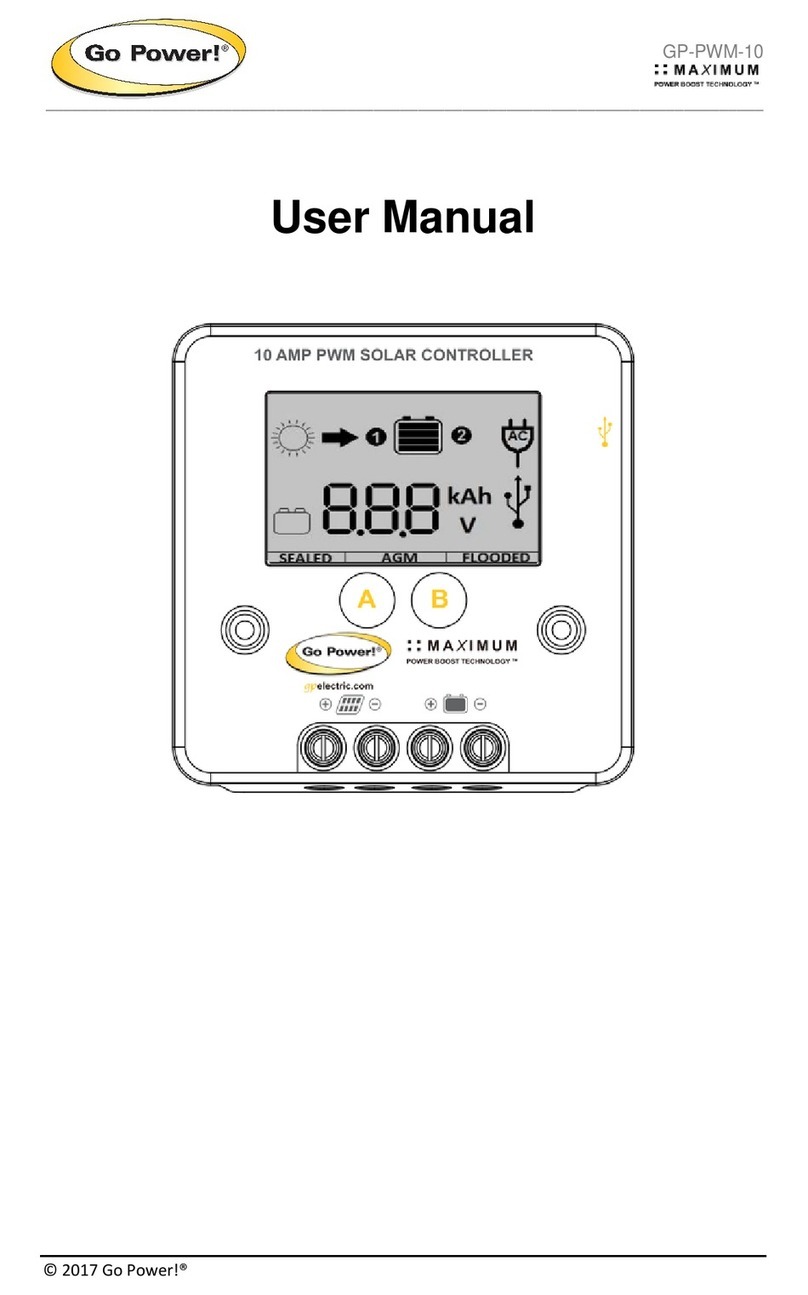

The GP-PWM-10-SQ is designed to be mounted against a wall, out of the way but easily visible.

The GP-PWM-10-SQ should be:

• Mounted as close to the battery as possible

• Mounted on a vertical surface to optimize cooling of the unit

• Indoors, protected from the weather

Solar should connect directly to the controller. Positive and negative battery connections must connect directly from the controller to

the batteries. Use of a positive or negative distribution bus is allowed between the controller and battery as long as it is properly sized,

electrically safe and an adequate wire size is maintained. Note: In a RV, the most common controller location is above the refrigerator.

The wire from the solar array most commonly enters the RV through the fridge vent on the roof..

4. INSTALLATION INSTRUCTIONS

1. Select wire type and gauge. If this GP-PWM-10-SQ was purchased as part of a Go Power! Solar Power Kit, appropriate wire

type, gauge and length is provided. Please continue to Section 5, “Operating Instructions.” If the GP-PWM-10-SQ was purchased

separately, follow the instructions included here. Wire type is recommended to be a stranded aluminum UV resistant wire. Wire

fatigue and the likelihood of a loose connection are greatly reduced in stranded wire compared to solid wire. Wire gauge should

be able to sustain rated current as well as minimizing voltage drop.

Suggested Minimum Wire Gauge

(Cable length 25 ft. max. from solar array to battery bank)

80 Watt Solar Module #12 Wire Gauge

95 Watt Solar Module #10 Wire Gauge

170 Watt Solar Module #10 Wire Gauge

190 Watt Solar Module #10 Wire Gauge

For other applications, please refer to standard wire guide.

Identify the polarity (pos. and neg.) on the cable used for the battery and solar module. Use colored wires or mark the

wire ends with tags. Although the GP-PWM-10-SQ is protected, a reverse polarity contact may damage the unit

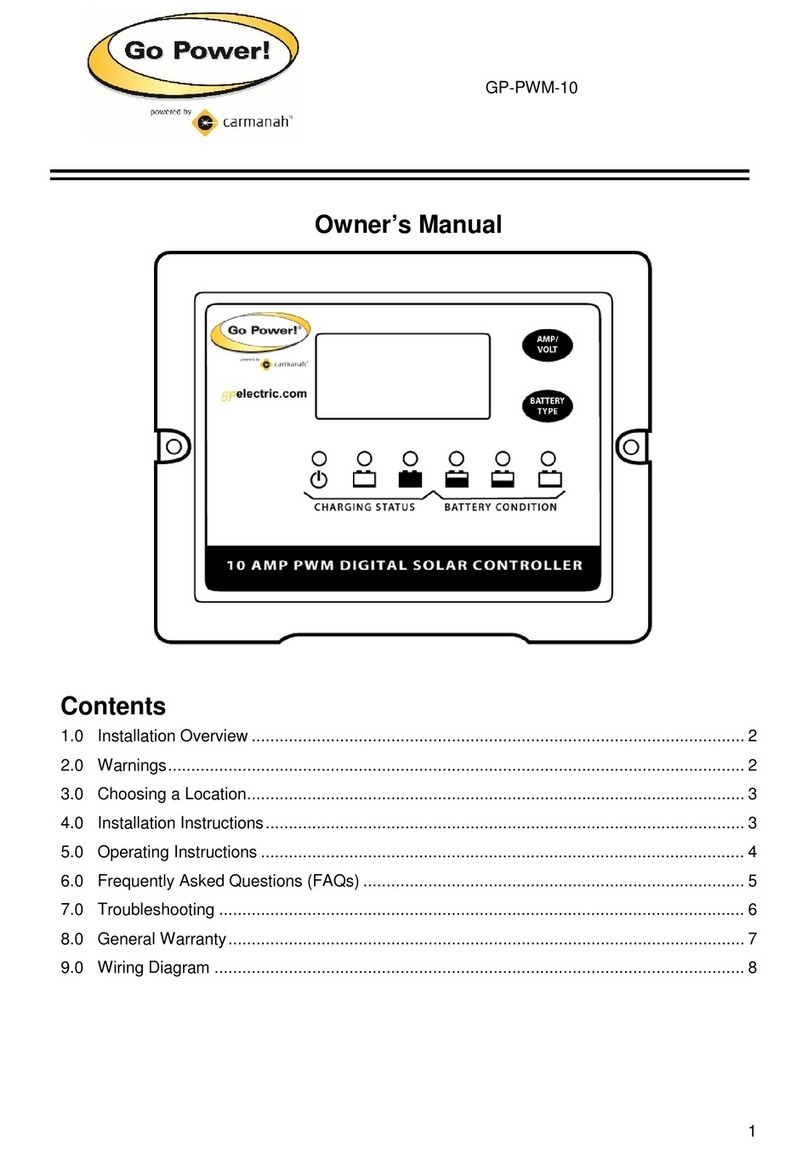

2. Wiring the GP-PWM-10-SQ. Wire the GP-PWM-10-SQ according to the wiring schematic in Section 8. Run wires from the solar

array and the batteries to the location of the GP-PWM-10-SQ. Keep the solar array covered with an opaque material until all wiring

iscompleted.Torqueallterminalscrewsto16inchpounds(1.8N.m).Connectthebatterywiringtothecontrollerrstandthen

connect the battery wiring to the battery

Use appropriate circuit protection on any conductor attached to a battery.

With battery power attached, the controller should power up and display information. Connect the solar wiring to the controller

and remove the opaque material from the solar array. The negative solar array and battery wiring must be connected directly to

the controller for proper operation. Do not connect the negative solar array or negative battery controller wiring to the chassis

of the vehicle.

3. Mounting the GP-PWM-10-SQ. Mount the GP-PWM-10-SQ to the wall using the included two mounting screws. After 30 days

of operation, re-torque all terminal screws to ensure the wires are properly secured to the controller. Congratulations, your GP-

PWM-10-SQ should now be operational. If the battery power is low and the solar array is producing power, your battery should

begin to charge.

You must set the battery type on the GP-PWM-10-SQ before you begin to use the controller. See section 5.2

3. CHOOSING A LOCATION