gpelectric.com | [page 3]

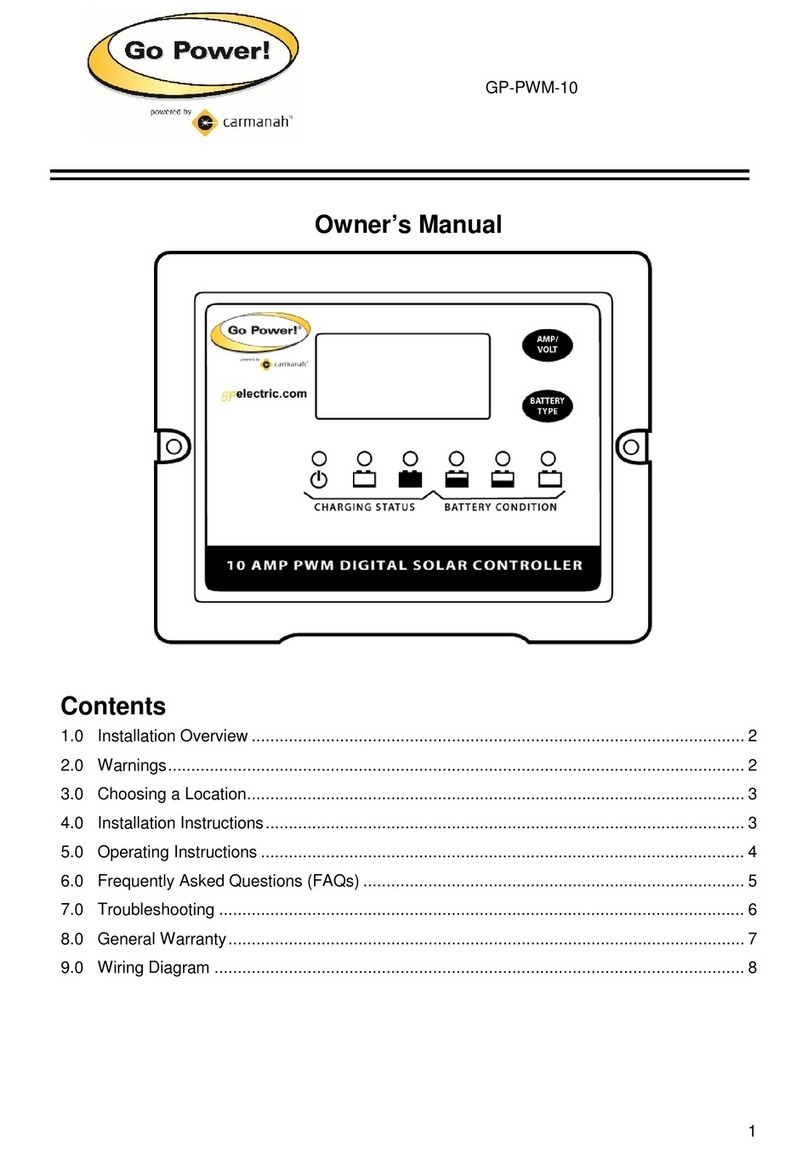

CONTENTS

1. INTRODUCTION.......................................................................................................................5

1.1 SAFETY PRECAUTIONS .................................................................................................................................5

1.2 OVERVIEW.......................................................................................................................................................6

1.3 FEATURES .......................................................................................................................................................6

1.4 APPEARANCE..................................................................................................................................................7

1.5 MPPT TECHNOLOGY INSTRUCTIONS ..........................................................................................................8

1.6 CHARGING STAGE INSTRUCTIONS........................................................................................................... 10

2. INSTALLATION.......................................................................................................................11

2.1 TOOLS AND MATERIALS NEEDED...............................................................................................................11

2.2 INSTALLATION AND WIRING ....................................................................................................................... 12

3. PRODUCT OPERATION AND DISPLAY...............................................................................14

3.1 LED INDICATION........................................................................................................................................... 14

3.1.1 PV INDICATOR ................................................................................................................................... 14

3.1.2 BATTERY INDICATOR........................................................................................................................ 14

3.1.3 LOAD INDICATOR .............................................................................................................................. 15

3.1.4 ERROR INDICATOR........................................................................................................................... 15

3.2 KEYS OPERATION........................................................................................................................................ 15

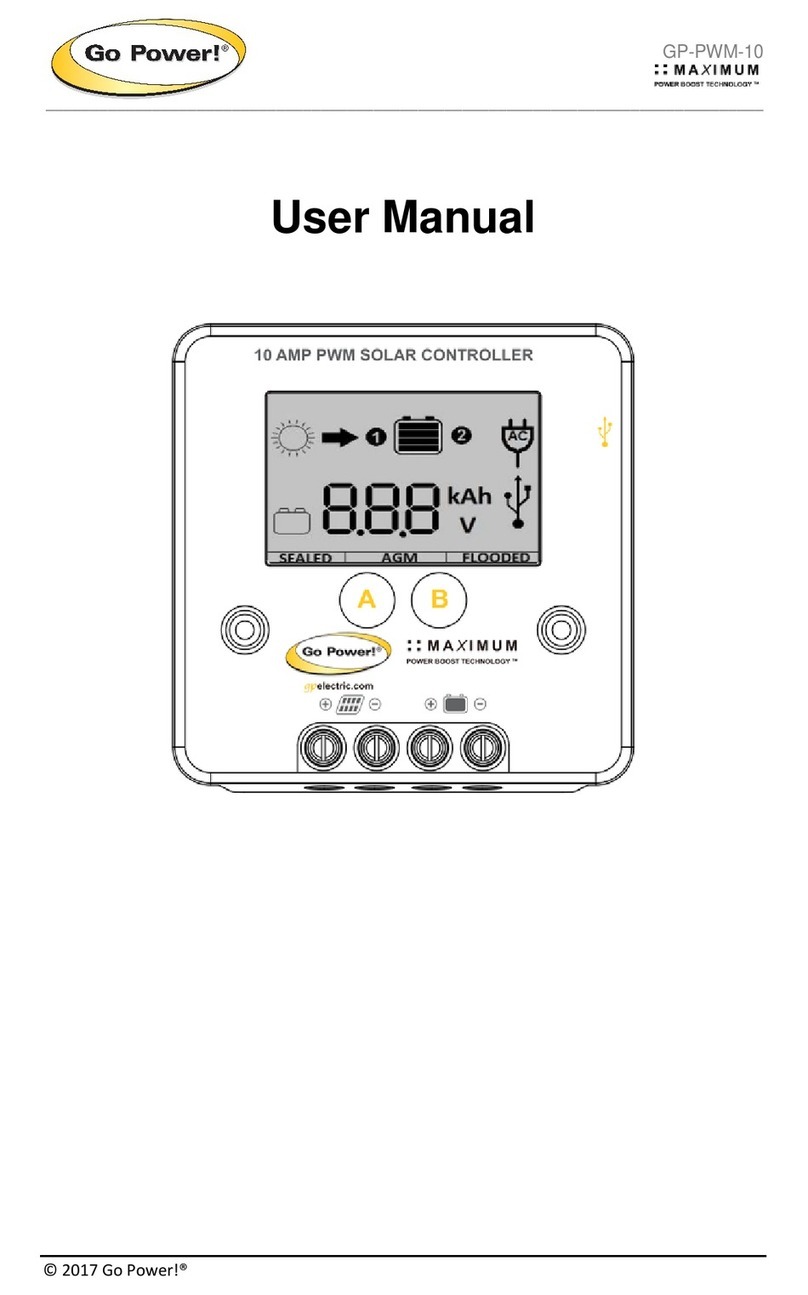

3.3 LCD STARTUP AND MAIN INTERFACE ....................................................................................................... 15

3.3.1 STARTUP INTERFACE....................................................................................................................... 16

3.3.2 MAIN INTERFACE .............................................................................................................................. 16

3.4 LOAD MODE SETTING INTERFACE............................................................................................................ 17

3.4.1 LOAD MODE INTRODUCTION .......................................................................................................... 17

3.4.2 LOAD MODE ADJUSTMENT.............................................................................................................. 17

3.4.3 MANUAL MODE ON/OFF PAGE ........................................................................................................ 17

3.5 SYSTEM PARAMETER SETTINGS .............................................................................................................. 18

4. SYSTEM MAINTENANCE......................................................................................................19

4.1 ABNORMALITY DISPLAY AND WARNINGS................................................................................................. 19

5. TECHNICAL PARAMETERS..................................................................................................20

5.1 ELECTRICAL PARAMETERS......................................................................................................................... 20

5.2 BATTERY TYPE DEFAULT PARAMETERS ................................................................................................... 21

6. CONVERSION EFFICIENCY CURVE....................................................................................21

6.1 12V SYSTEMS............................................................................................................................................... 21

6.2 24V SYSTEMS............................................................................................................................................... 22

7. PRODUCT DIMENSIONS.......................................................................................................22

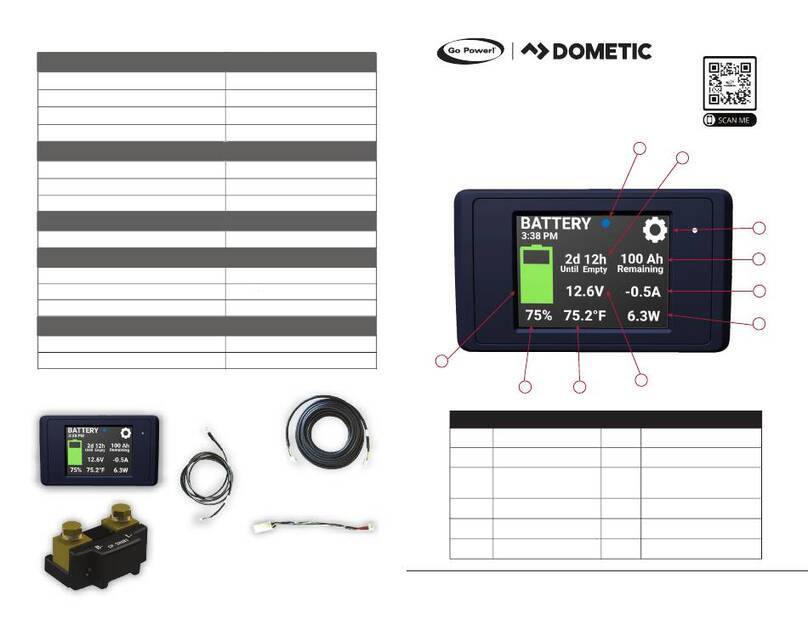

8. BLUETOOTH®DONGLES......................................................................................................23

8.1 PRODUCT INFORMATION ........................................................................................................................... 23

8.2 MAIN FEATURES .......................................................................................................................................... 23

8.3 LED STATUS ................................................................................................................................................. 23

8.4 APPLICABLE TYPE ...................................................................................................................................... 23

8.5 PRODUCT FEATURES ................................................................................................................................. 24

8.6 PRODUCT DIMENSIONS ............................................................................................................................. 24

8.7 SYSTEM WIRING DIAGRAM ....................................................................................................................... 25

8.8 SPECIFICATIONS ......................................................................................................................................... 25

www.earth911.com/recycling-center-search-guides